Cable shaft and cables applied into cable shaft

A technology for cable shafts and shafts, applied in the direction of insulating cables, cables, circuits, etc., can solve problems such as short-circuit fire, aging, etc., and achieve the effect of reducing the temperature of flue gas and inhibiting the spread of fire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

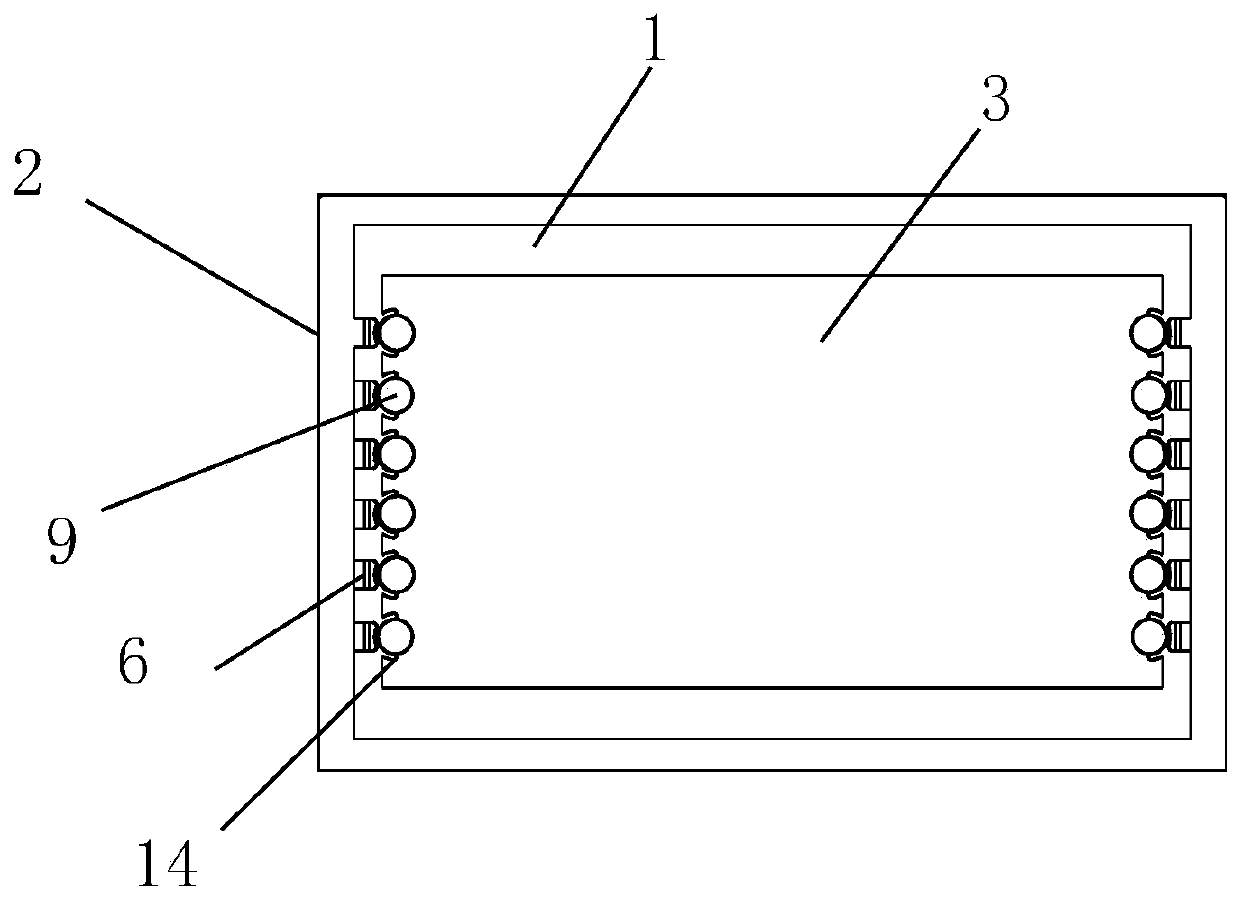

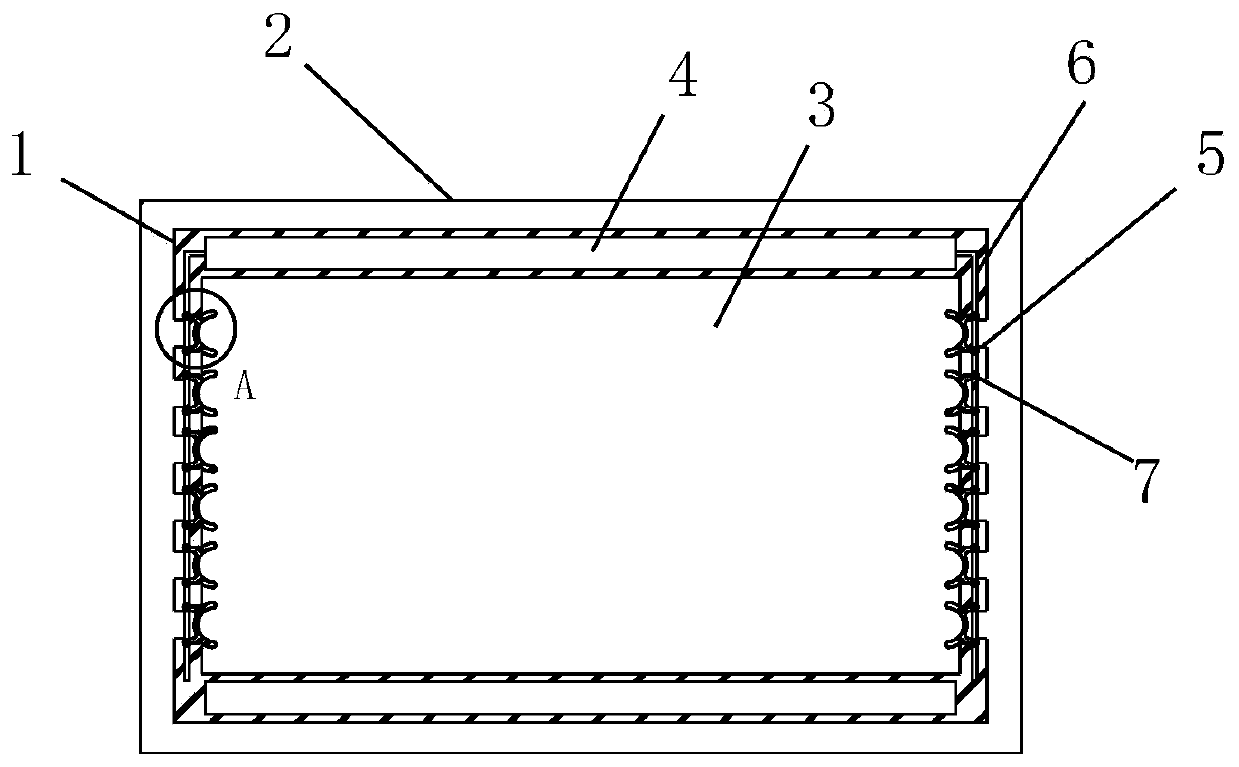

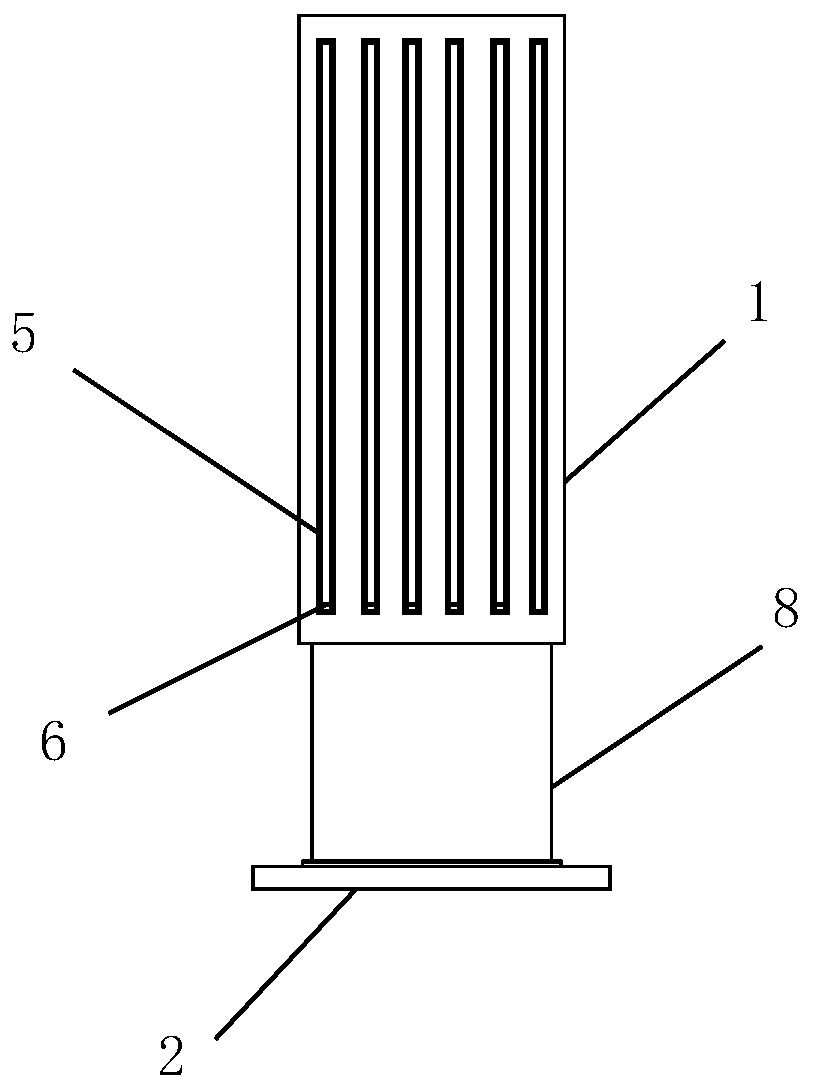

[0018] Such as Figure 1-Figure 5 As shown, a cable shaft includes a shaft main body, the shaft main body includes a base 2, two sealing support plates 8 and a shaft box 1, a shaft cavity 3 is provided in the middle of the shaft box 1, and the two sides of the shaft cavity 3 are provided with More than one cable clamp 14, each cable clamp 14 has an arc-shaped clamping cavity, the opening end of the clamping cavity is provided with an arc-shaped limit opening, and each arc-shaped clamping cavity is equipped with Enter a cable 9 and limit the position through the arc-shaped limit port. The cables 9 are all arranged perpendicular to the horizontal plane. An open slot 5 is provided on the outer surface of the shaft box facing each clamping cavity. The bottom surface of the open slot 5 is Set up a cooling groove 13, the cooling groove 13 and the opening groove 5 are all extended along the height direction of the shaft main body, and the cable 9 part is buckled in the cooling groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com