Ultrasonic detecting device and detecting method for automobile resin tailgate

A detection device, ultrasonic technology, applied in the direction of measuring device, using sound wave/ultrasonic wave/infrasonic wave to analyze solid, fluid tightness test, etc. It can solve the problems of not being able to see the leakage intuitively, time-consuming and laborious, air pressure leakage, etc., to achieve a solution Clean up time-consuming and labor-intensive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

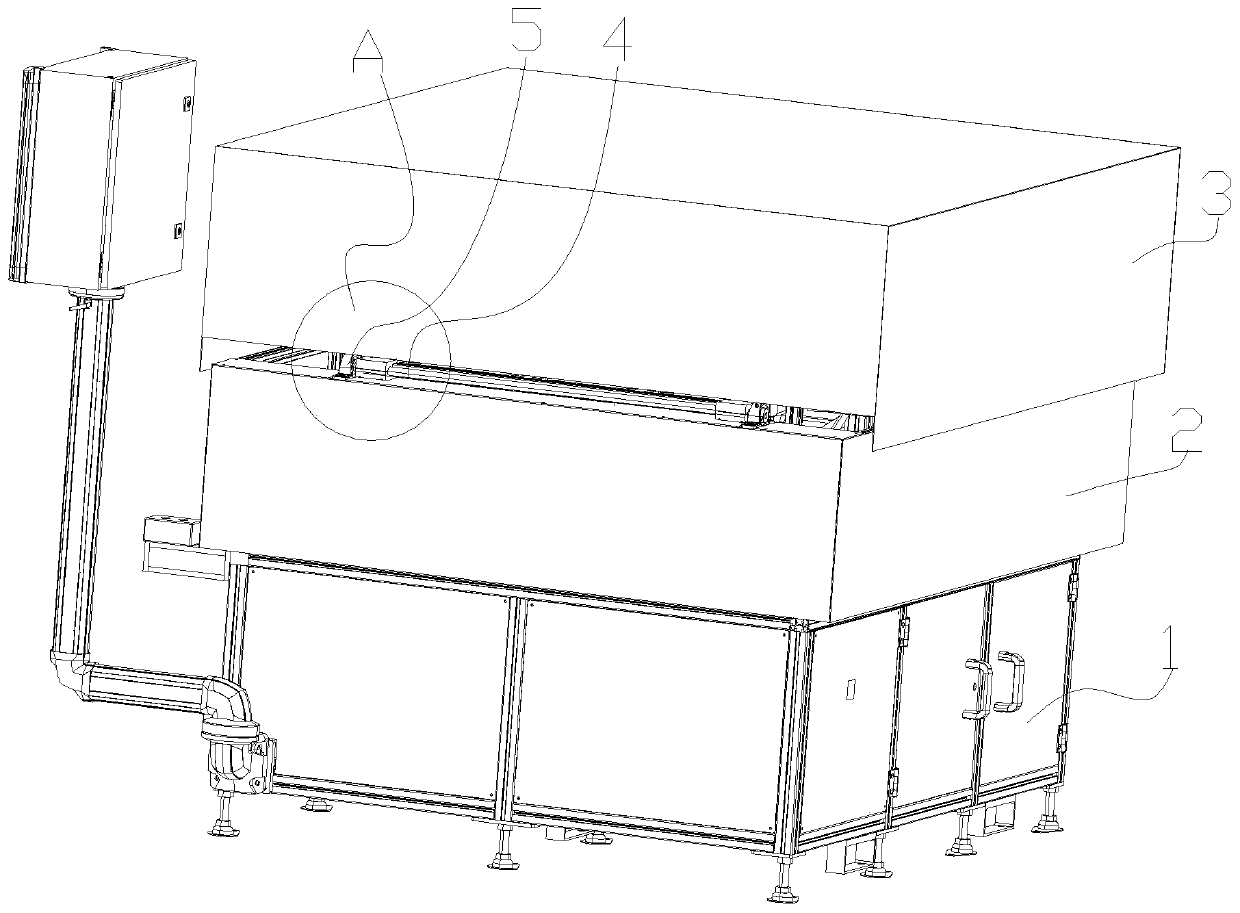

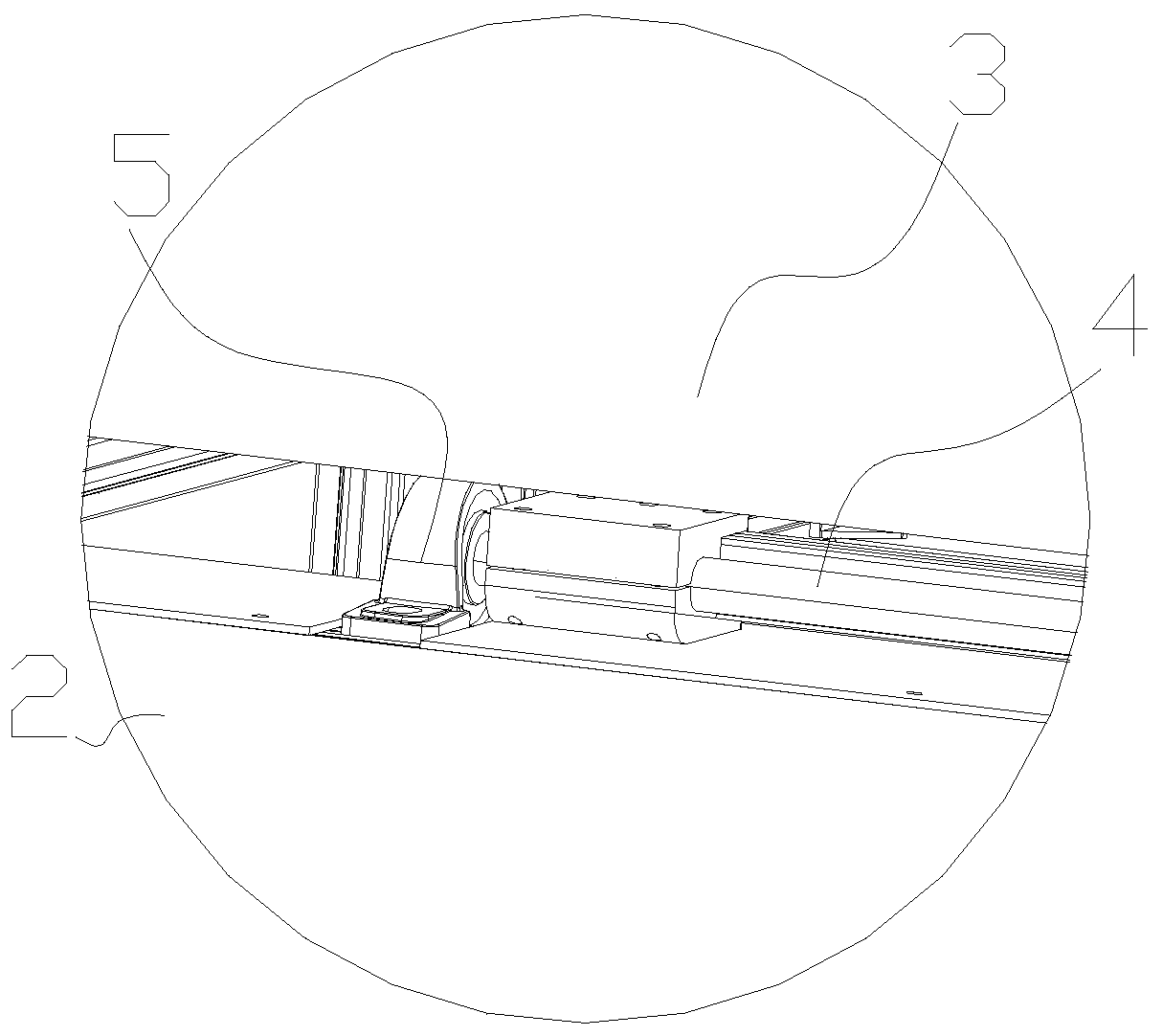

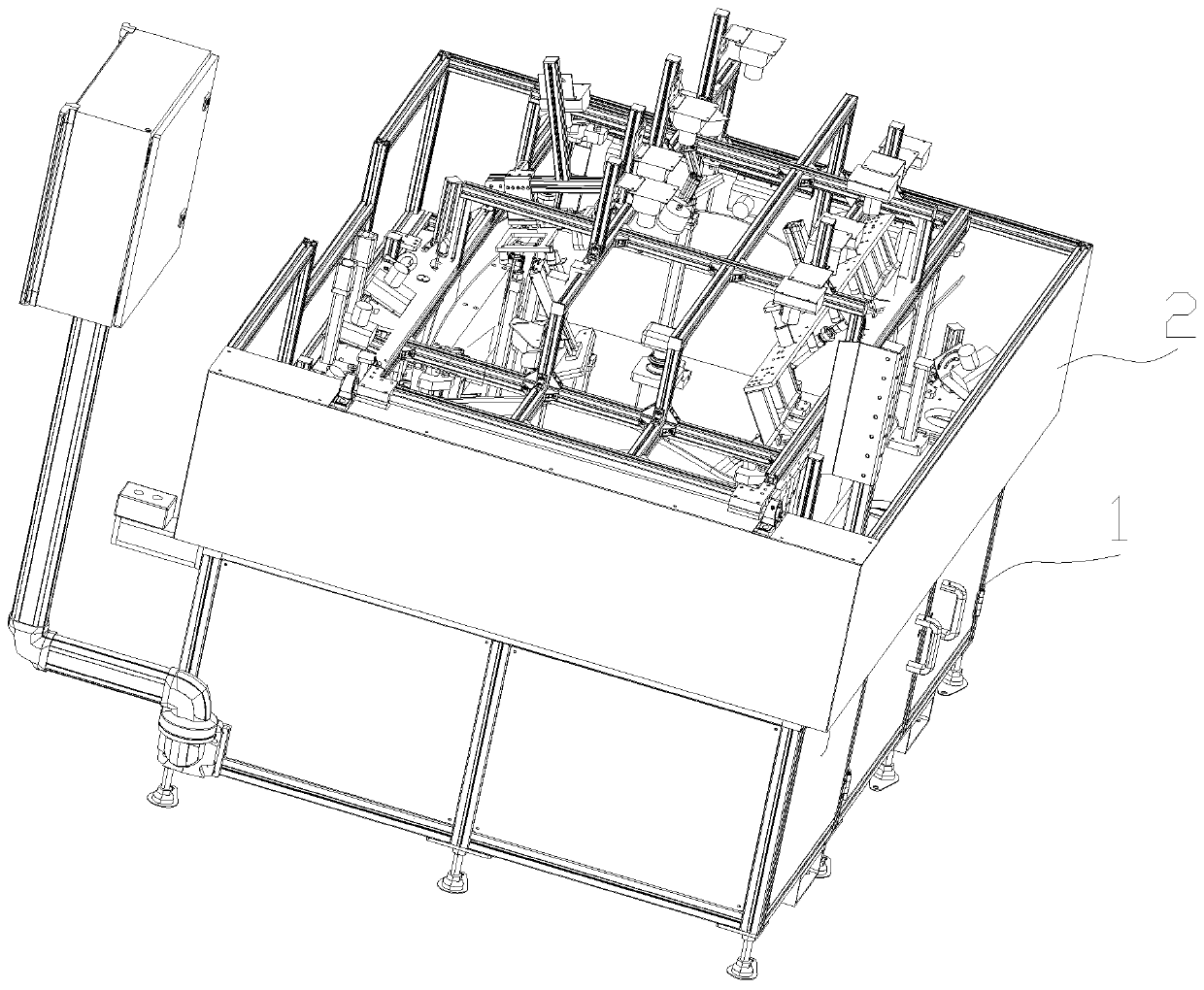

[0033] refer to Figure 1 to Figure 13 A kind of automobile resin tailgate ultrasonic detection device shown, comprises electric cabinet 1 and is located at the detection box body of electric cabinet 1 top, and detection box body is equipped with ultrasonic detection device inside, and described detection box consists of lower box body 2 and upper The lower box body 2 is horizontally installed on the upper end of the electrical cabinet 1, the upper cover plate 3 is hinged on the upper end of the lower box body 2, the side end of the upper cover plate 3 is provided with a horizontally arranged rotating shaft 4, and the lower box body 2 The upper end of one of the side plates is provided with an upper cover plate installation hinge seat 5, and the upper cover plate 3 is rotationally connected with the upper cover plate installation hinge seat 5 through a rotating shaft 4. The ultrasonic detection device is composed of an ultrasonic transmitter and an ultrasonic connection device....

Embodiment 2

[0038] refer to Figure 1 to Figure 13 A kind of automobile resin tailgate ultrasonic detection device shown, comprises electric cabinet 1 and is located at the detection box body of electric cabinet 1 top, and detection box body is equipped with ultrasonic detection device inside, and described detection box consists of lower box body 2 and upper The lower box body 2 is horizontally installed on the upper end of the electrical cabinet 1, the upper cover plate 3 is hinged on the upper end of the lower box body 2, the side end of the upper cover plate 3 is provided with a horizontally arranged rotating shaft 4, and the lower box body 2 The upper end of one of the side plates is provided with an upper cover plate installation hinge seat 5, and the upper cover plate 3 is rotationally connected with the upper cover plate installation hinge seat 5 through a rotating shaft 4. The ultrasonic detection device is composed of an ultrasonic transmitter and an ultrasonic connection device....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com