A method for determining the yield point of w/o waxy crude oil emulsion

A determination method and emulsion technology, applied in the direction of using a stable shear force to test the strength of materials, instruments, measuring devices, etc., can solve the problem that the yield point is not easy to read accurately, and achieve the effect of enriching research progress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

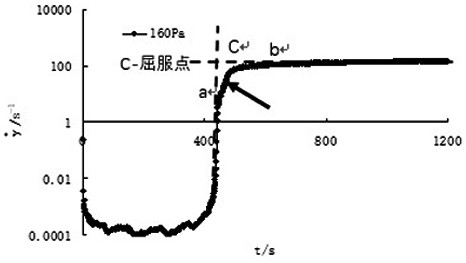

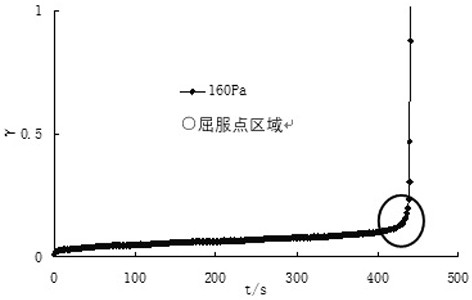

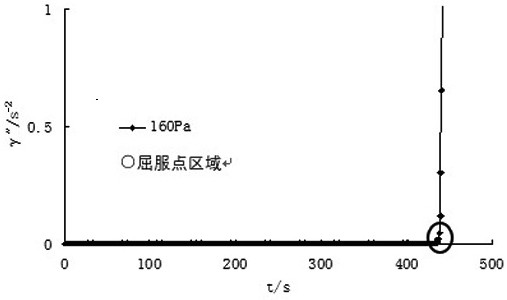

[0038] The method for determining the yield point of W / O waxy crude oil emulsion under the experimental condition of 34℃ under the loading condition of linear increase of stress, includes the following steps:

[0039] 1. The preparation of the waxy crude oil experimental sample, that is, the pretreatment, the specific operations are as follows:

[0040] After the crude oil samples are taken from the production site and transported to the laboratory in sealed oil drums, the crude oil is fully stirred, and then packed into appropriate grinding-mouth bottles to be sealed and stored as experimental oil samples with the same composition; Put it in a water bath, let it stand and heat to 80°C, and keep it at a constant temperature for 2 hours, then take out the experimental oil sample and let it stand at room temperature, cool it naturally, and store it in a place where the ambient temperature changes little for more than 48 hours, as the base oil sample prepared by the emulsion .

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dew point | aaaaa | aaaaa |

| yield stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com