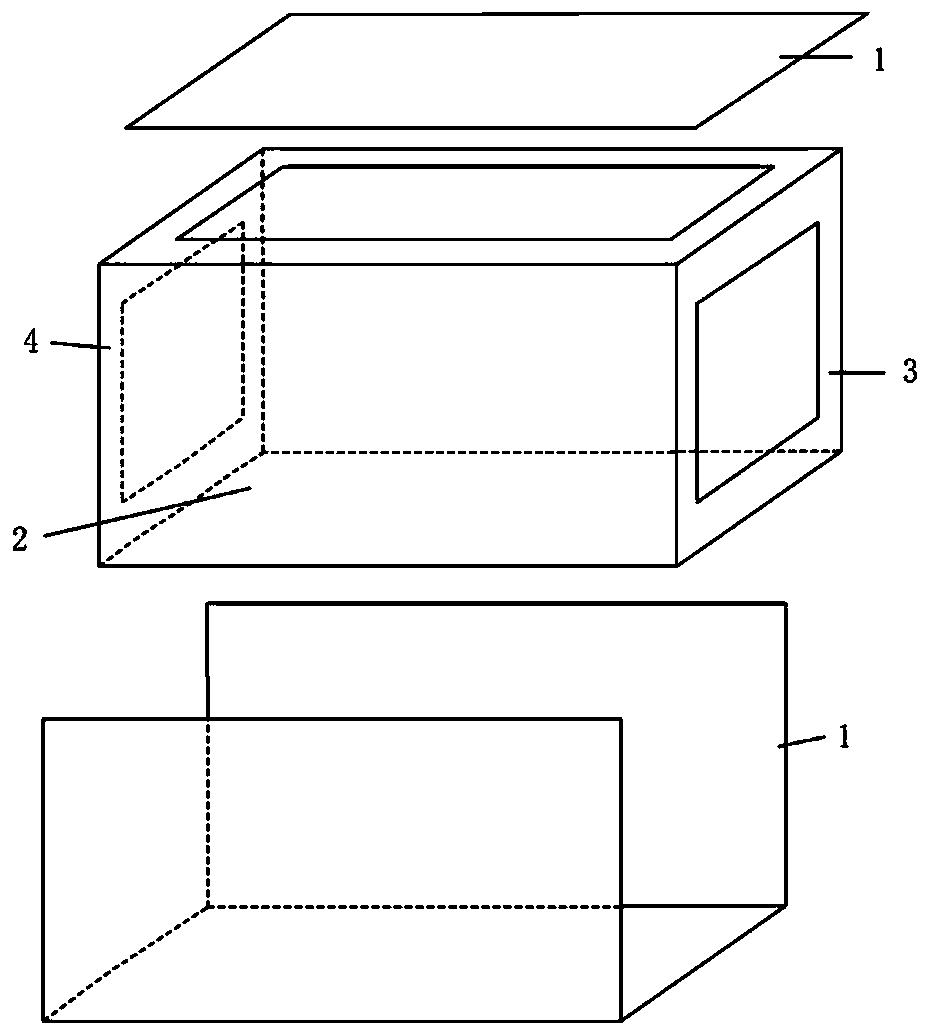

Sealing method and device suitable for large three-way loading permeameter

A technology of sealing device and permeation instrument, which is applied in the field of experimental theory, can solve problems such as danger, discounting of test results, and spraying in the gap between the upper cover and the lower instrument body, so as to ensure sealing, ensure rationality, and meet seepage The effect of research needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1, a kind of high-pressure penetration test sealing method, has adopted described sealing method, comprises the steps:

[0032] Step 1: Return all push plates of the instrument to their original positions;

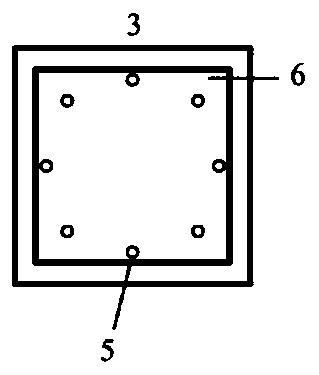

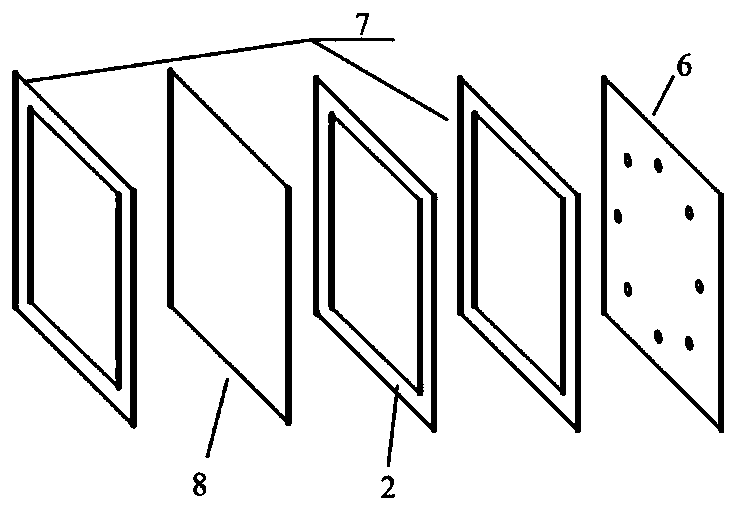

[0033] Step 2: Glue a circular rubber sheet around the water inlet hole of the water inlet push plate and the water outlet hole of the water outlet plate, and place a rubber sheet inside the test chamber. The rubber sheet covers the front, bottom and rear sides of the instrument ( Except for the water inlet surface, water outlet surface and top), the specific size and model of the rubber sheet is determined by the calculated peak shear strength and the thickness of the rubber sheet allowed by the instrument;

[0034] Step 3: Put in the custom-made water bladder, place the geotextile and the rubber sheet in sequence on the water inlet side of the bladder body, and place the rubber sheet on the water outlet side;

[0035]Step 4: Fill the test soil sample f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com