Cleaning system of central air-conditioning air outlet pipeline

A central air-conditioning and cleaning system technology, applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of dust carry-over, poor cleaning effect, etc., and achieve the effect of convenient and safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

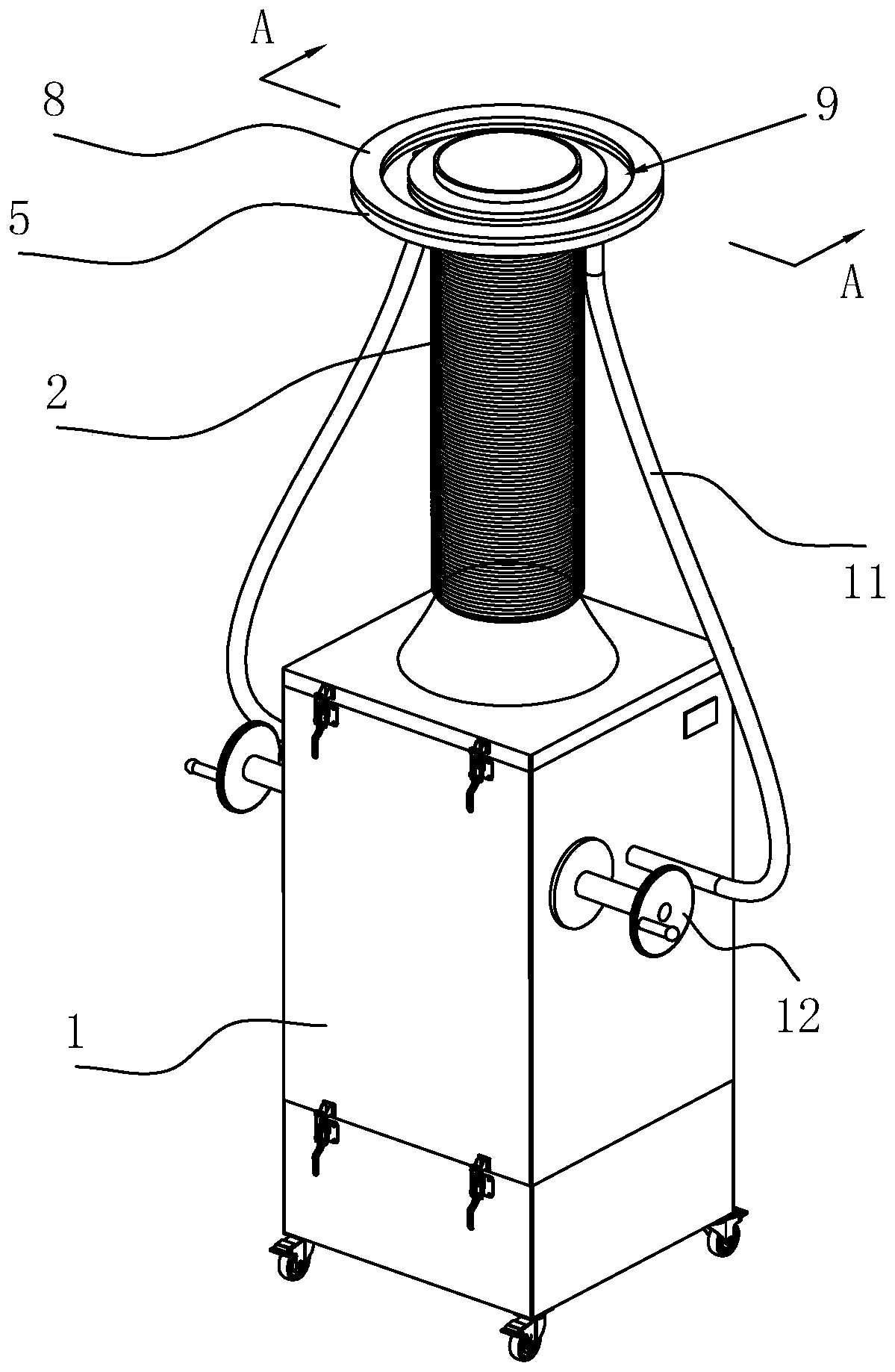

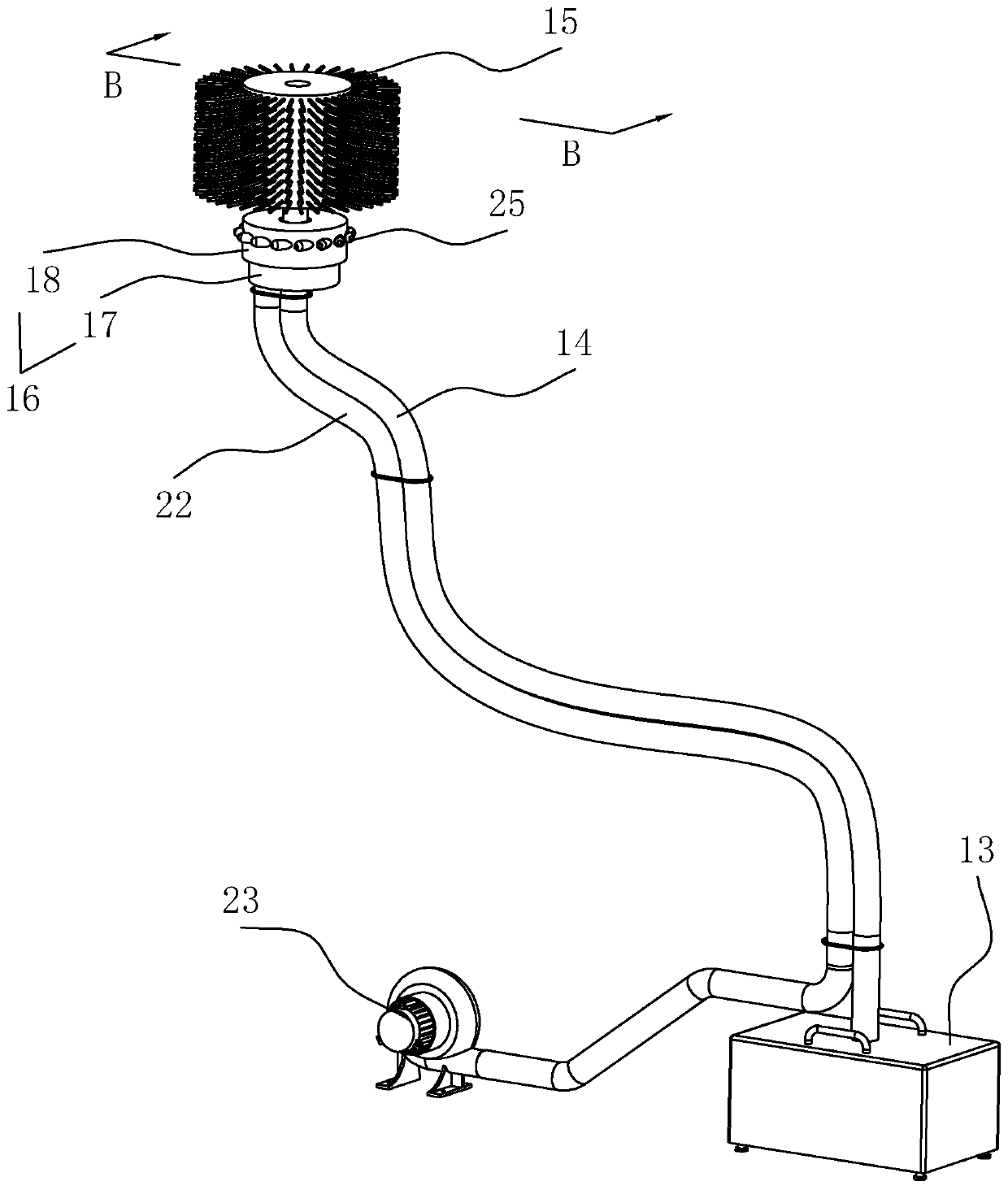

[0035] refer to figure 1 , is a central air-conditioning air outlet duct cleaning system disclosed in the present invention, including a flexible shaft 14 machine for vibrating and dusting the inner wall of the air outlet duct and a dust collector installed under the air outlet of the air duct for extracting dust in the air duct machine.

[0036] refer to figure 1 , a dust collector, comprising a blower body 1 and a blower hose 2 connected to the top of the blower body 1, and a blower motor (not shown) connected with the blower hose 2 is arranged in the blower body 1 .

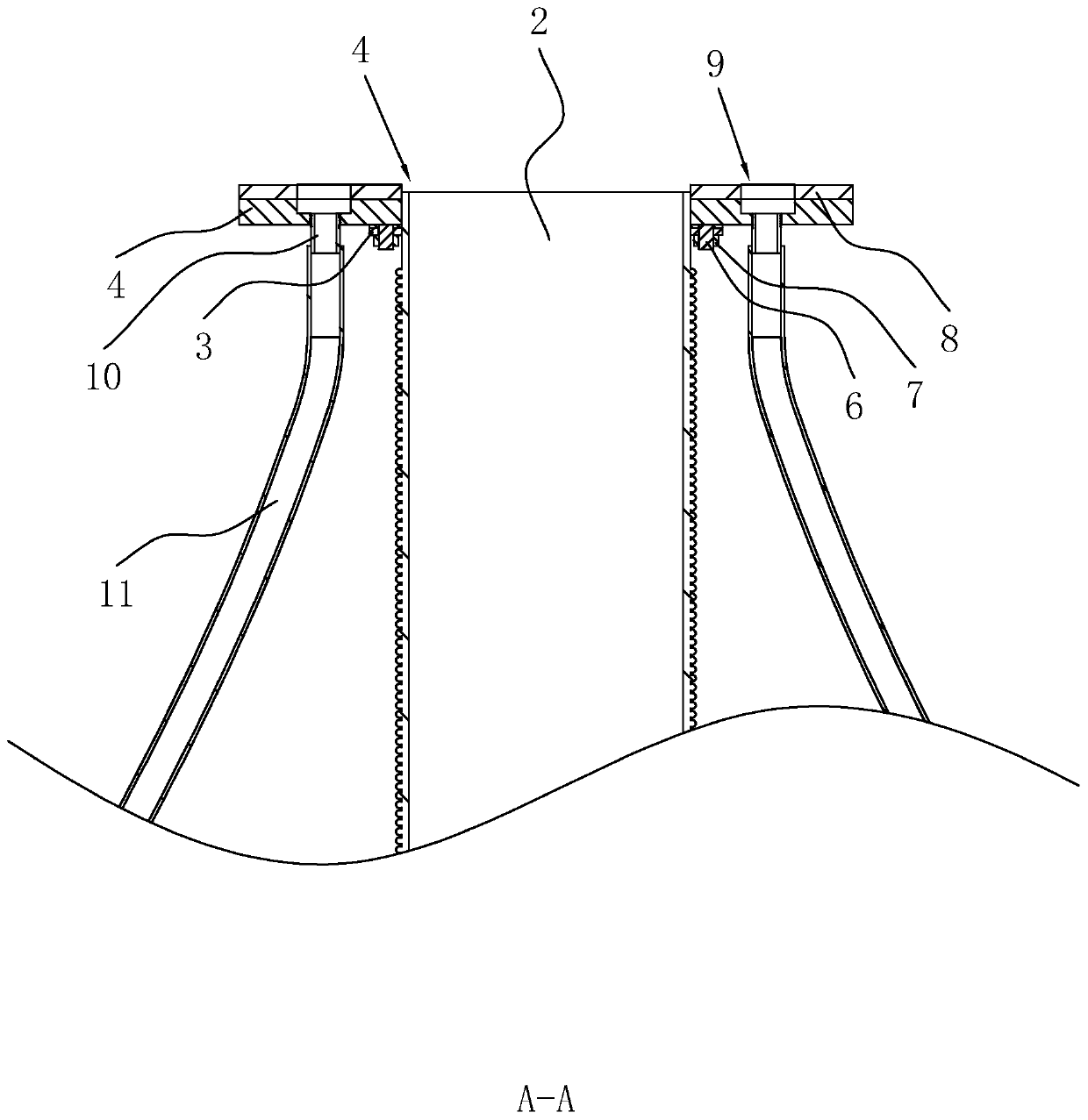

[0037] refer to figure 1 and figure 2 The end of the exhaust hose 2 away from the exhaust body 1 is hooped and fixed with a ring-shaped mounting plate 3 on the outer wall, and on the side of the installation plate 3 away from the exhaust body 1, a device for connecting the exhaust hose 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com