Deposited metal of stainless steel welding rod for fast reactor

A technology of deposited metal and stainless steel, which is applied in the field of deposited metal, can solve problems such as insufficient strength, low impact toughness, and failure to meet the technical requirements for welding of fast stack metal pumps, etc., and achieves no intergranular corrosion tendency and stable comprehensive mechanical properties and the effect of corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0013] Specific Embodiment 1: In this embodiment, a deposited metal of a stainless steel electrode for fast stacking, the mass fraction of the chemical composition of the deposited metal is C: 0.04% to 0.08%, Si: 0.30% to 0.90%, and Mn: 1.00 %~2.50%, P≤0.025%, S≤0.020%, Cr: 17.00%~20.00%, Ni: 11.00%~14.00%, Mo: 2.00%~3.00%, N: 0.02%~0.12%, the balance is Fe, and the ferrite content is 3FN~7FN.

[0014] The beneficial effect of this implementation mode:

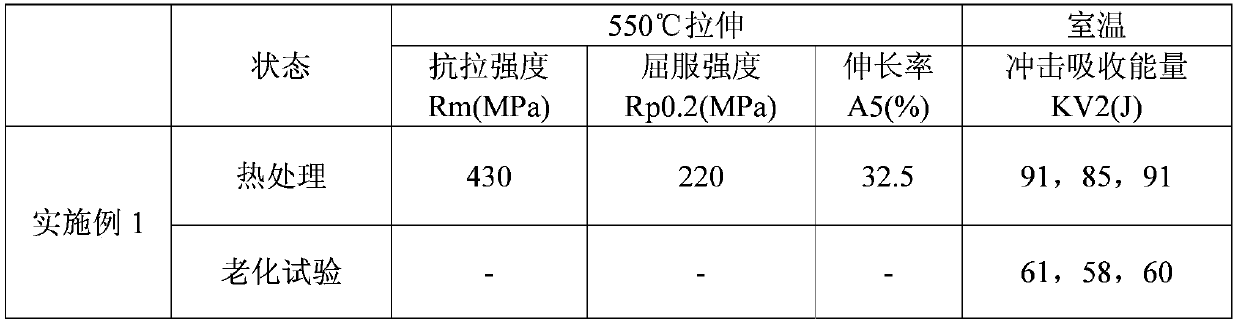

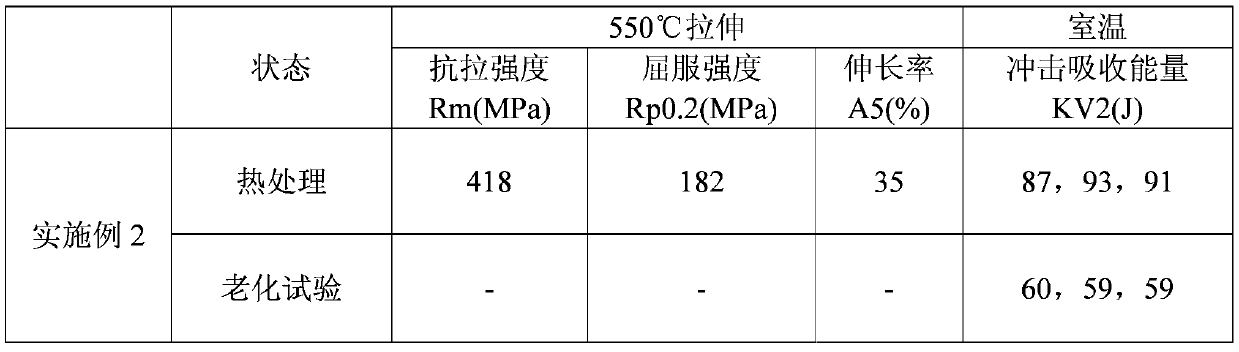

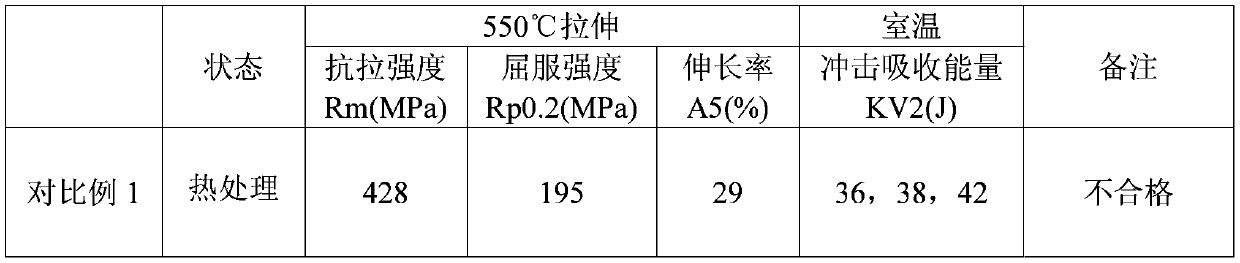

[0015] 1. The deposited metal of a stainless steel electrode for fast stacking in this embodiment has high tensile strength at 550°C after heat treatment at 975°C×2h (Rm≥402MPa), room temperature impact KV2 can be stably greater than 60J, after aging test ( Impact energy KV after 975℃×2h+750℃×100h) 2 More than 25J, it has good and stable comprehensive mechanical properties and corrosion resistance, and has no intergranular corrosion tendency, which fully meets the technical requirements of fast reactor metal pump welding.

...

specific Embodiment approach 2

[0018] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is: the mass fraction of the chemical composition of the deposited metal is C: 0.05%-0.07%, Si: 0.30%-0.90%, Mn: 1.00%-2.50 %, P≤0.020%, S≤0.015%, Cr: 17.00%~20.00%, Ni: 11.00%~14.00%, Mo: 2.00%~3.00%, N: 0.02%~0.12%, the balance is Fe, and The ferrite content is 4FN~6FN.

[0019] Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0020] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the mass fraction of the chemical composition of the deposited metal is C: 0.050%, Si: 0.44%, Mn: 2.10%, P: 0.018%, S: 0.006%, Cr: 18.97%, Ni: 11.56%, Mo: 2.49%, N: 0.065%, the balance is Fe, and the ferrite content is 5.5FN.

[0021] Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impact energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com