Double-side polishing device for steel plate rust removal

A steel plate, double-sided technology, used in grinding drives, grinding machines, grinding feed movements, etc., can solve problems such as low work efficiency, and achieve the effect of wide application range and novel design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

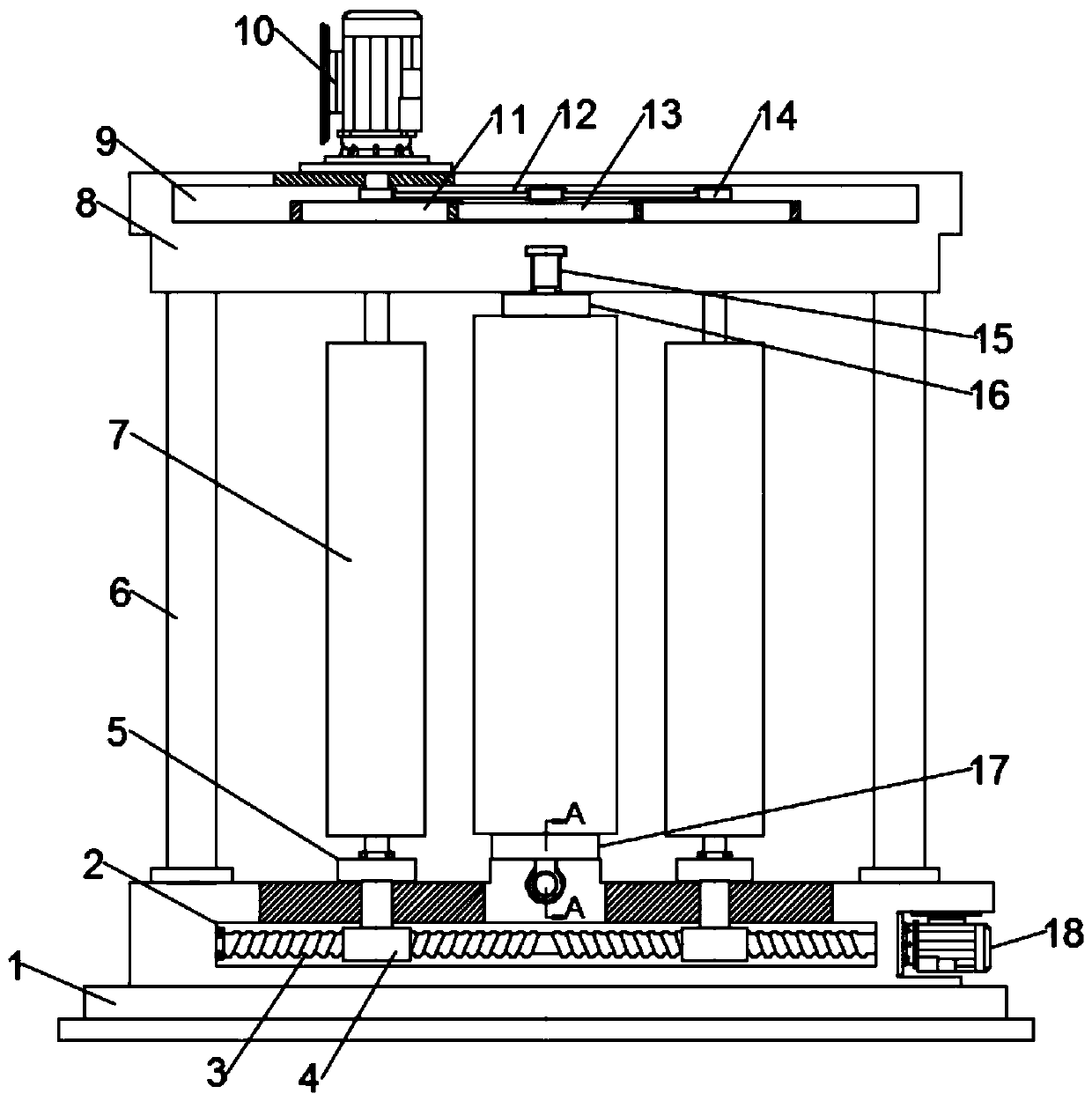

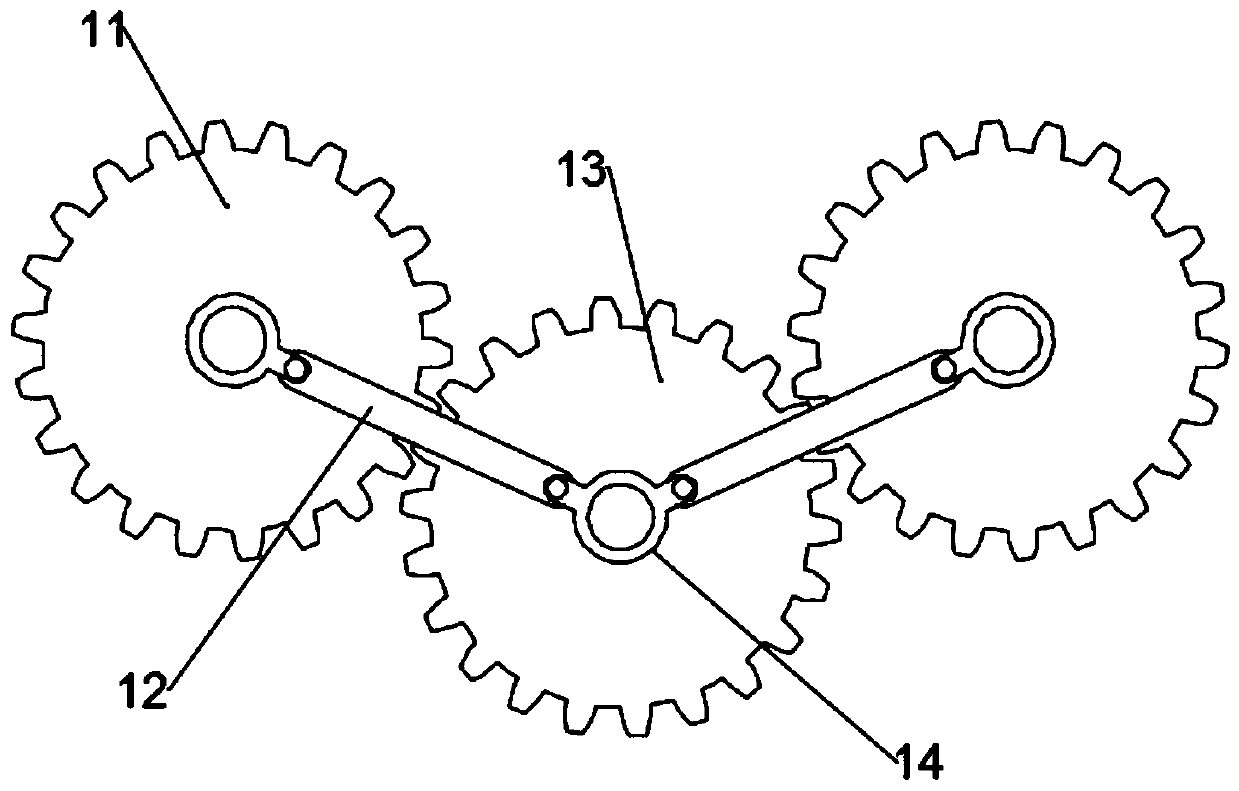

[0023] see Figure 1~4 , in an embodiment of the present invention, a double-sided grinding device for derusting steel plates includes a base 1 and a top plate 8 fixed to the base 1 through a bracket 6; two grinding rollers are arranged between the base 1 and the top plate 8 7. The lower ends of the two grinding rollers 7 are respectively rotated and installed on two receiving blocks 5, and the two receiving blocks 5 are connected with the driving assembly arranged on the base 1. When the driving assembly is working, the receiving blocks 5 are driven to move towards each other or vice versa. movement, so as to realize the adjustment of the distance between the two grinding rollers 7, realize the derusting treatment of different steel plates, and have a wide range of applications. The output shaft of 10 is fixedly connected, and the rotating shaft of the grinding roller 7 located inside the transmission chamber 9 is rotationally connected with the rotating shaft on the other gr...

Embodiment 2

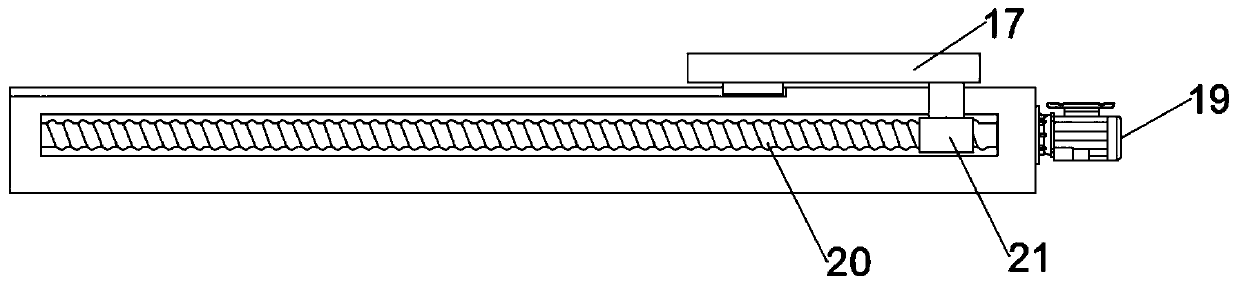

[0029] see Figure 5 , in the specific implementation process of the present invention, in order to ensure the stability of the steel plate during the conveying process, the present invention also proposes another embodiment to improve the present application, specifically, the upper end side of the second extrusion plate 17 An extension plate is provided, and the extension plate is perpendicular to the second extruding plate 17. After the steel plate is installed, the extension plate abuts against one side of the steel plate, so that when the steel plate is transported, the extension plate plays a role of limiting and pushing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com