Hub positioning clamp

A technology for positioning fixtures and hubs, applied in manufacturing tools, workpiece clamping devices, etc., can solve problems such as being easily scratched and unable to solve the hub, and achieve the effect of improving the success rate of tire loading, simple structure and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

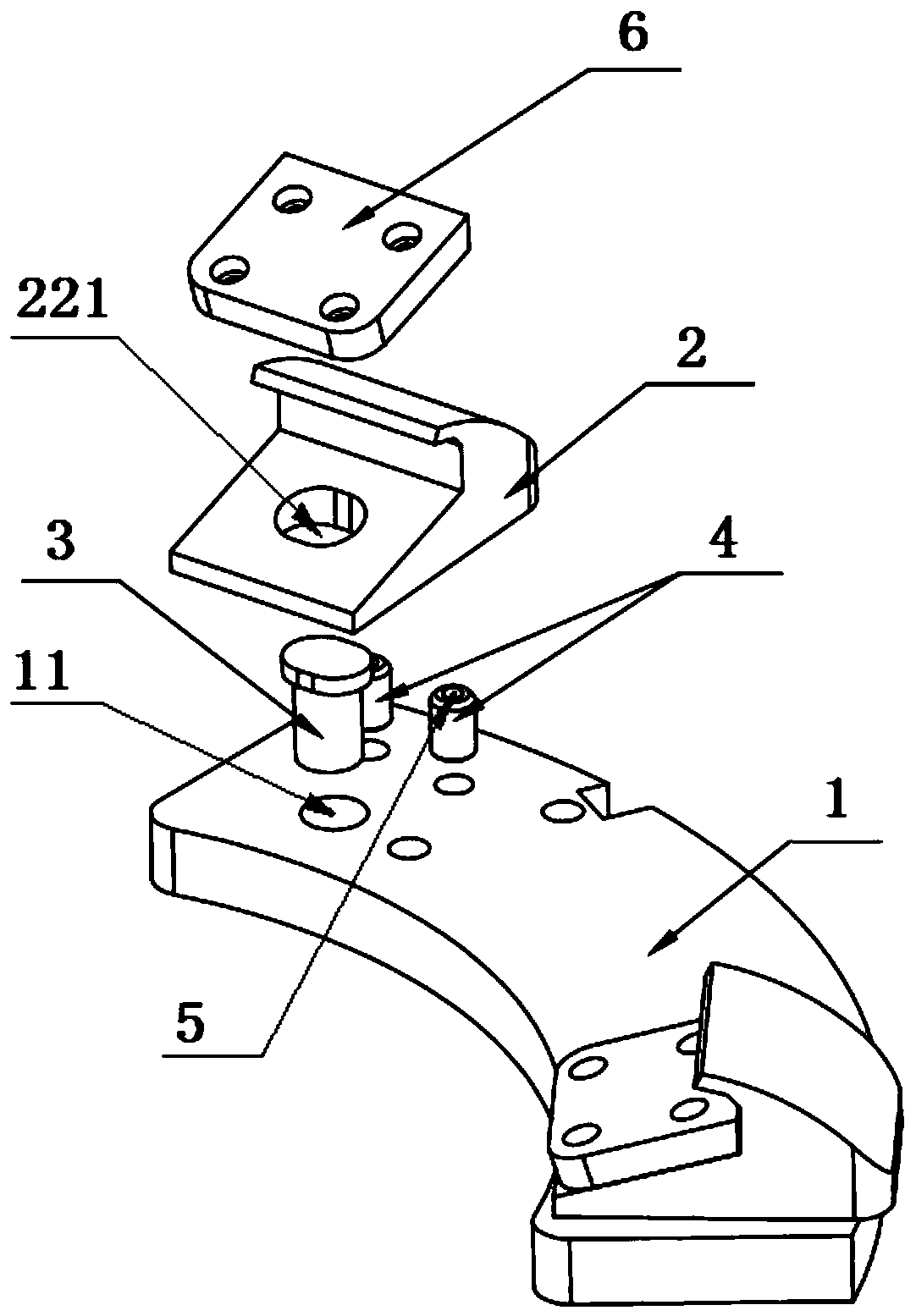

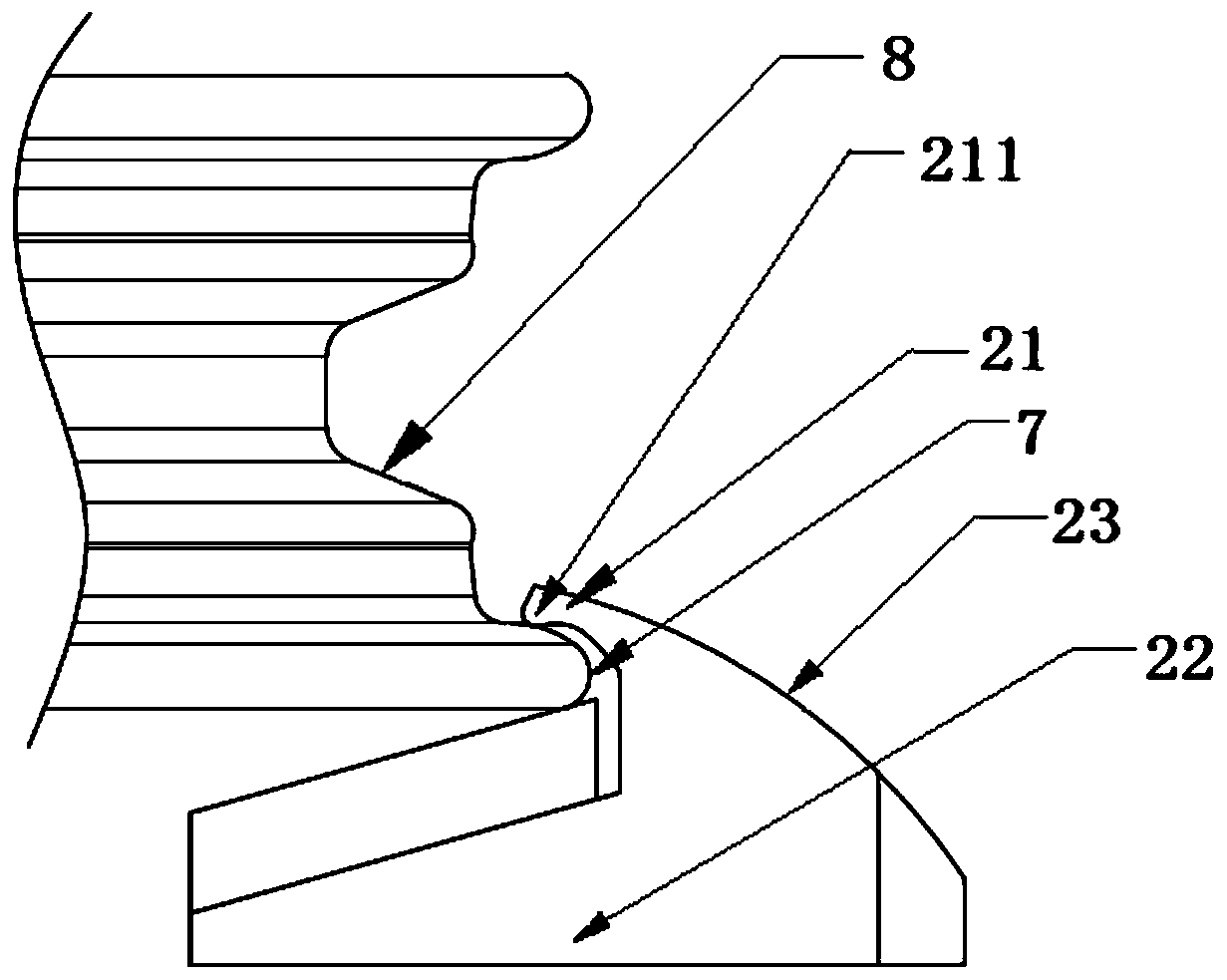

[0032] Such as figure 1 As shown, a hub positioning jig includes a jig base 1 and two jig jaws 2 installed at both ends of the jig base 1. The jig jaw 2 includes a support end 22, a jaw tail 23 connected to the support end 22, and a jaw that is connected to the clamp. The clamping end 21 connected to the claw tail 23 is provided with an arc-shaped protrusion 211 on the top of the clamping end 21, a first hole 221 is provided on the supporting end 22, and a second hole 11 is respectively provided at both ends of the clamp base 1. , the first pin 3 passes through the first hole 221 and the second hole 11 to install the clamp claw 2 on the clamp base 1 , and the clamp claw 2 rotates on the clamp base 1 with the first pin 3 as the axis.

[0033] Two second pins 4 are arranged on the outside of the first pin 3, and a ball 5 is arranged on the top of the second pin 4. touch. The second pin 4 is used for assisting the universal rotation of the clamp claw 2 on the clamp base 1. Due ...

Embodiment 2

[0040] The difference between this embodiment and Embodiment 1 is that the positioning of a hub is jointly completed by three hub positioning jigs. The above three hub positioning fixtures are evenly engaged on the hub, and the angle between any two adjacent hub positioning fixtures is 120°.

Embodiment 3

[0042] The difference between this embodiment and Embodiment 1 is that the positioning of a hub is jointly completed by four hub positioning jigs. The above four hub positioning fixtures are evenly engaged on the hub, and the angle between any two adjacent hub positioning fixtures is 90°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com