Pressing system for instrument processing

A technology of instruments and workbenches, which is applied in the field of pressing systems for instrument processing, can solve the problems of high manufacturing and use costs, time-consuming and labor-intensive use of pressing devices, and achieve the goal of reducing manufacturing and use costs, reducing the number of uses, and reducing the amount of use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

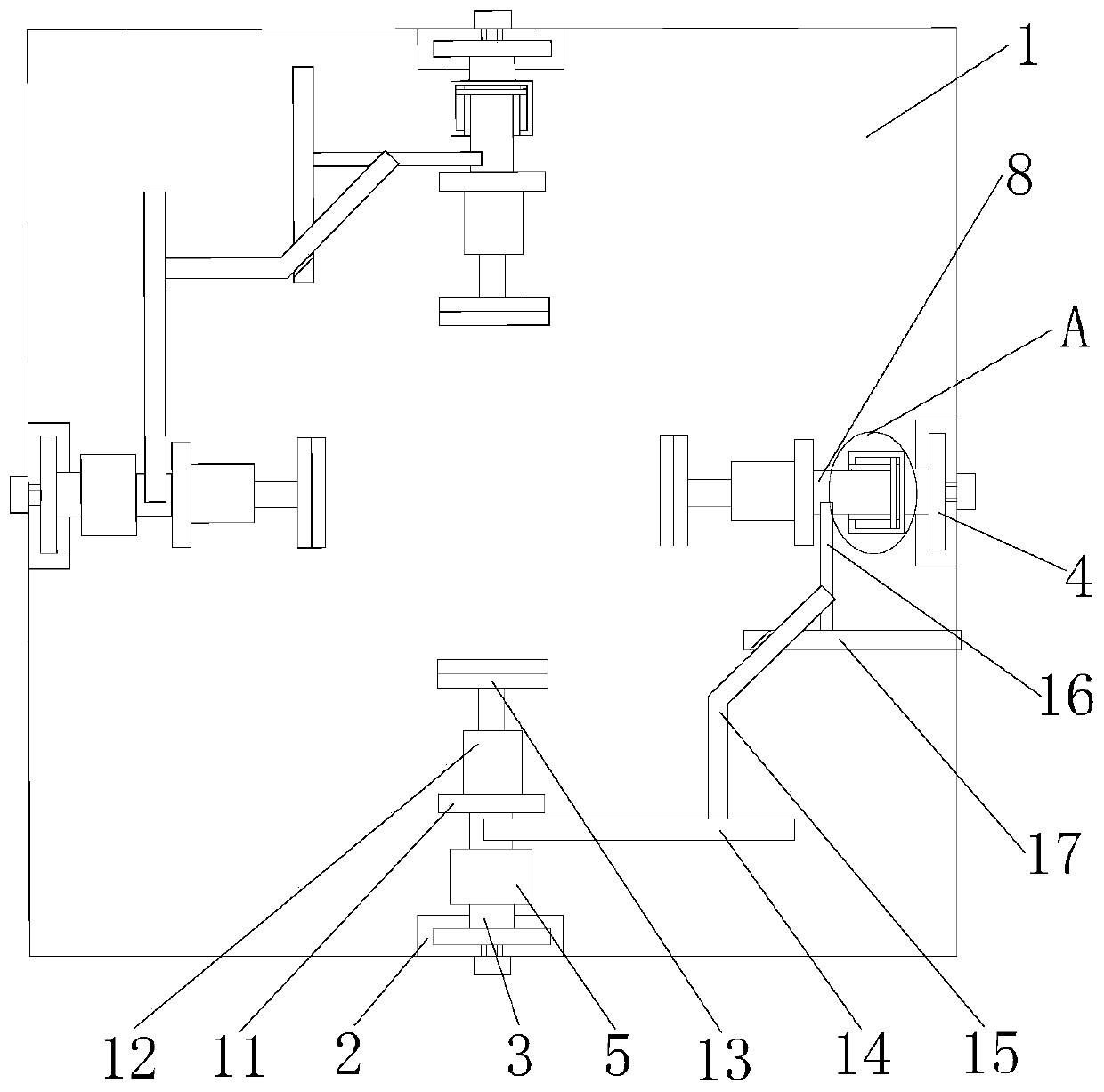

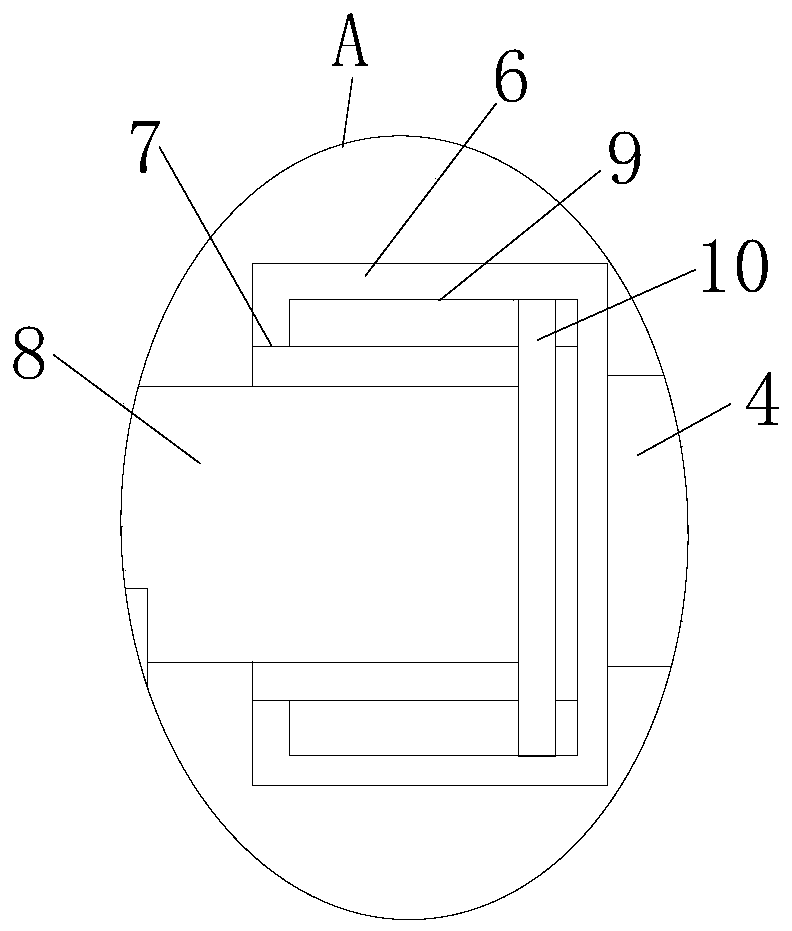

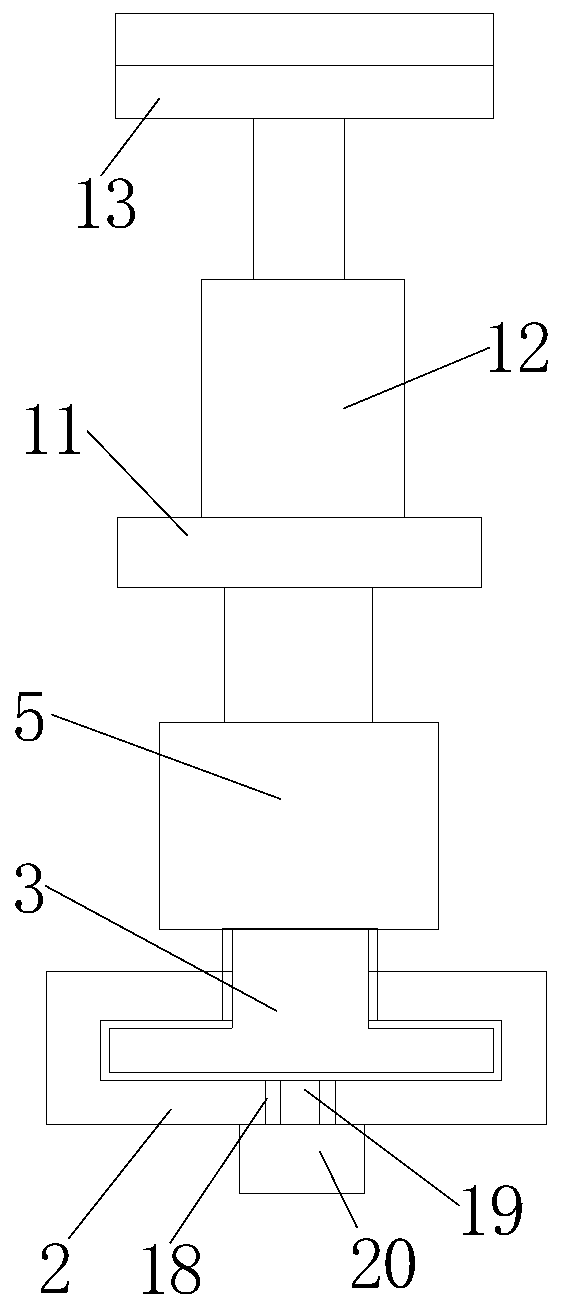

[0027] refer to Figure 1-5 , a pressing system for instrument processing, including a workbench 1, the four sides of the workbench 1 are provided with sliding sleeves 2, and the adjacent two sliding sleeves 2 are respectively provided with a first slider 3 and a second slider 4 , one side of the first slider 3 and the second slider 4 are respectively fixed with a cylinder 5 and a mounting block 6, and one side of the cylinder 5 and the mounting block 6 is provided with a supporting base 11, and one side of the supporting base 11 is provided with Elastic mechanism 12, one side of elastic mechanism 12 is provided with pressing plate 13, and one side of first slide block 3 and second slide block 4 is all fixedly installed with clamp bar 19, and one side of adjacent two sliding sleeves 2 is all opened There is a card slot 18, and one end of the two card bars 19 runs through the two card slots 18 respectively and is movably socketed with a card block 20. One side of the card block...

Embodiment 2

[0038] refer to Figure 1-5 , a pressing system for instrument processing, including a workbench 1, the four sides of the workbench 1 are provided with sliding sleeves 2, and the adjacent two sliding sleeves 2 are respectively provided with a first slider 3 and a second slider 4 One side of the first slider 3 and the second slider 4 are respectively fixedly installed with a cylinder 5 and a mounting block 6 by welding, and one side of the cylinder 5 and the mounting block 6 is provided with a support seat 11, and one side of the support seat 11 An elastic mechanism 12 is provided, and one side of the elastic mechanism 12 is provided with a pressing plate 13, and one side of the first slider 3 and the second slider 4 is fixedly installed with a clamping rod 19 by welding, and the adjacent two sliding sleeves 2 One side is provided with draw-in groove 18, and one end of two draw-in rods 19 runs through two draw-in grooves 18 respectively and is both movably socketed with clamp b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com