Clutch mechanism for imprinting device of printing machine

A clutch mechanism and printing machine technology, applied in printing machines, rotary printing machines, printing, etc., can solve the problems of processing influence, film effective length change, waste generation, etc., and achieve the effect of avoiding waste and avoiding influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

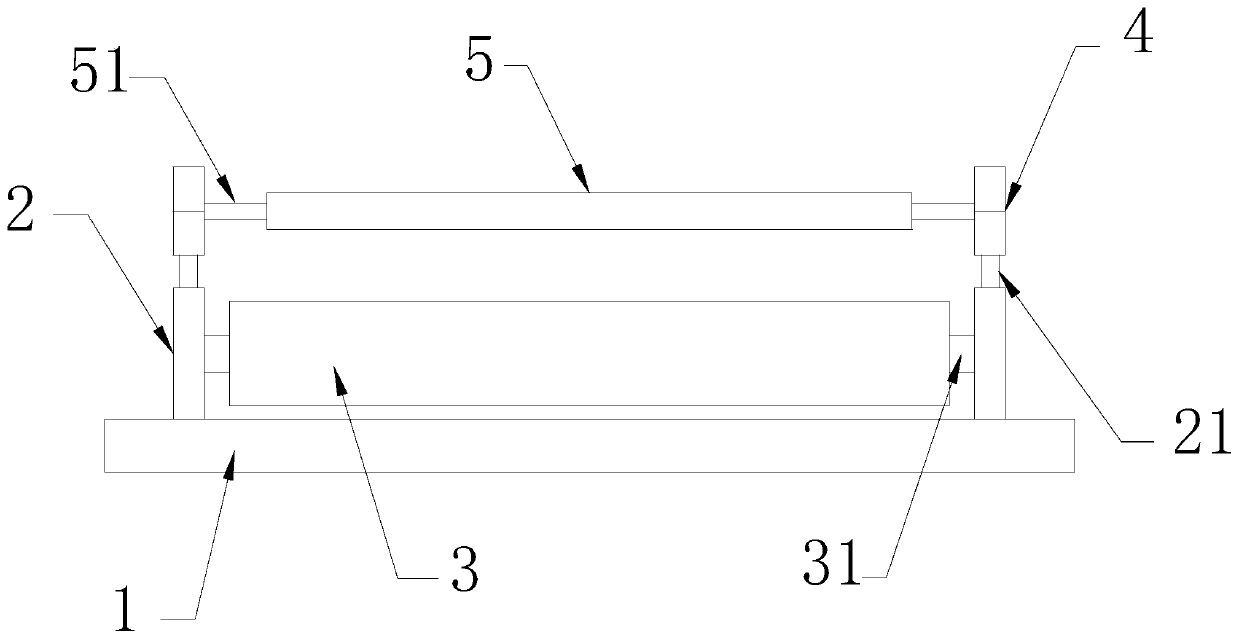

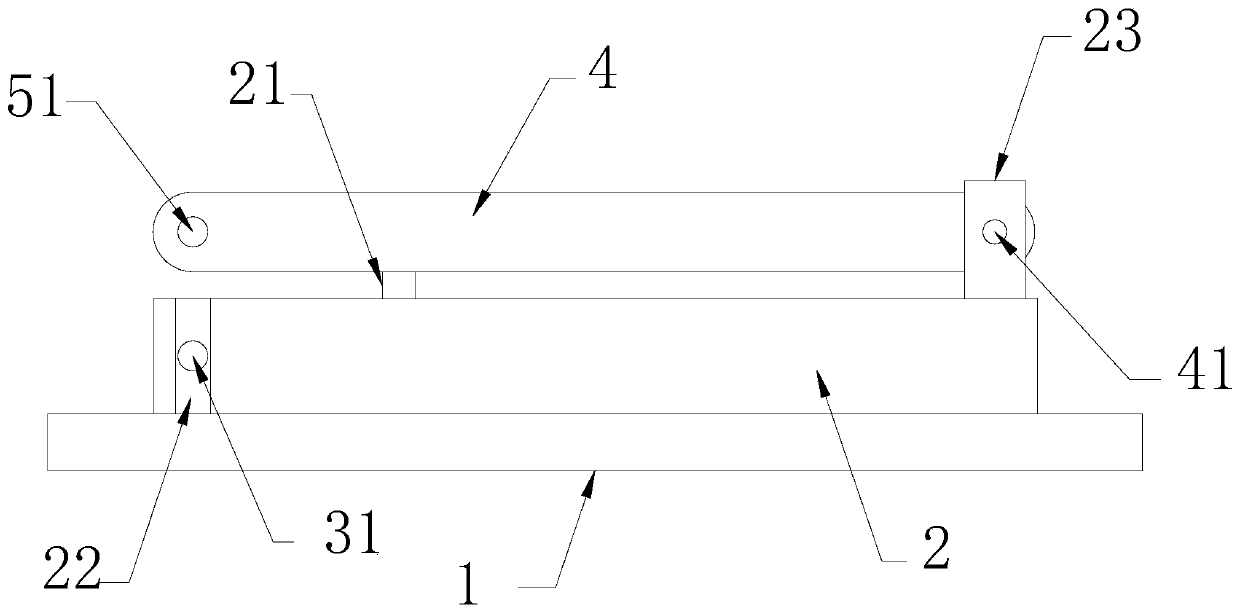

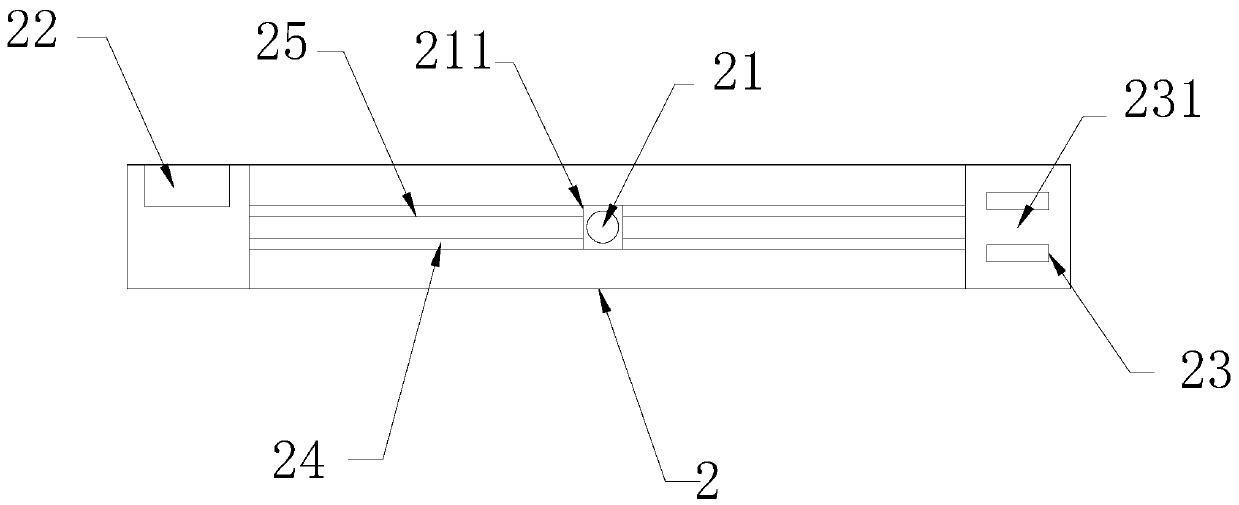

[0026] Example: such as Figure 1-6 As shown, the present invention provides a clutch mechanism of an embossing device of a printing machine, including a working base plate 1, a plate roller fixing bracket 2, a plate roller 3, an embossing roller fixing bracket 4, an embossing roller 5 and a controller. The roller fixing bracket 2 and the embossing roller fixing bracket 4 are all arranged in pairs, and are respectively arranged on both sides of the plate roller 3 and the embossing roller 5; 2. The whole is in the shape of a long strip. There are first rotating shafts 31 arranged on both sides of the printing roller 3. The printing roller 3 is installed on one end of the printing roller fixing bracket 2 through the first rotating shaft 31. The embossing roller fixing bracket 4 is installed on the printing roller fixing bracket 2. The other end of the bracket 2; the embossing roller fixing bracket 4 has the same length as the version roller fixing bracket 2, and the two ends of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com