Battery-replacement moving and carrying device capable of achieving floating without lateral force

A transfer device and lateral force technology, applied in the direction of power devices, electric power devices, charging stations, etc., can solve problems such as poor mobility, high infrastructure requirements, and limited space at the bottom of the vehicle, so as to reduce the vertical size and facilitate promotion Application, meet the effect of fast battery replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

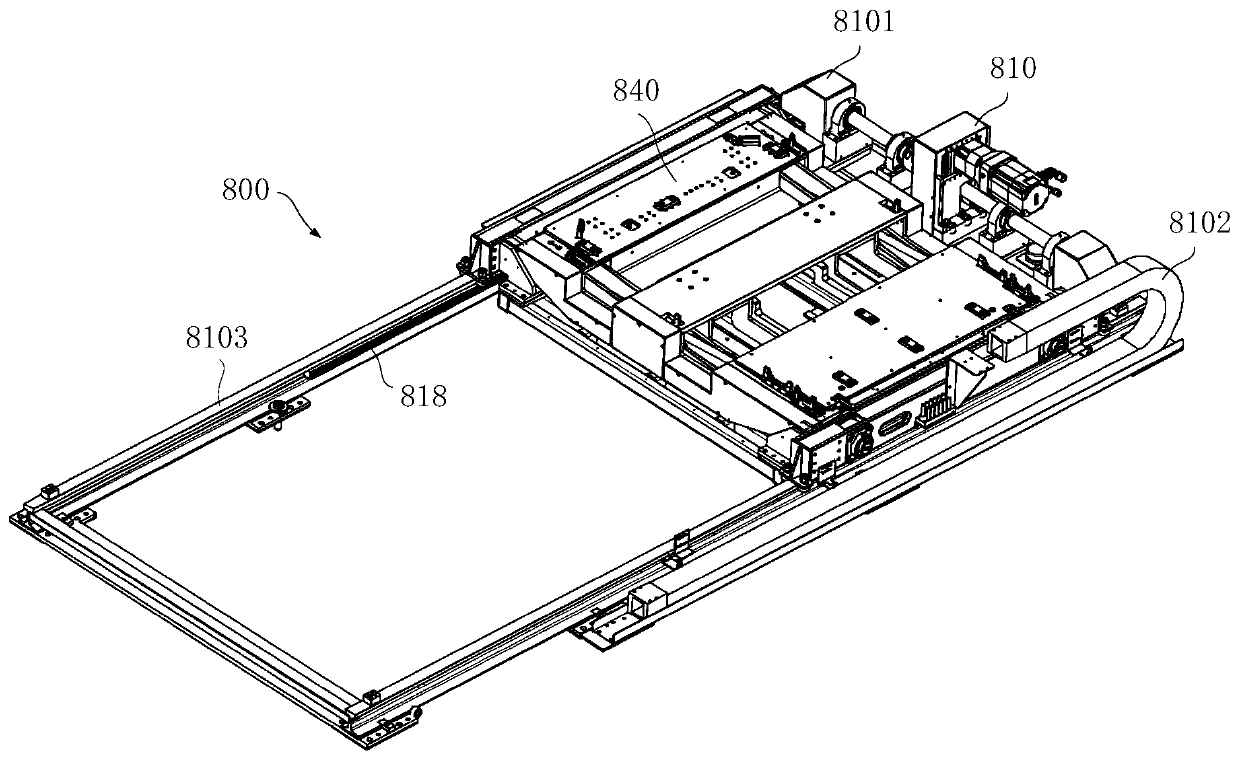

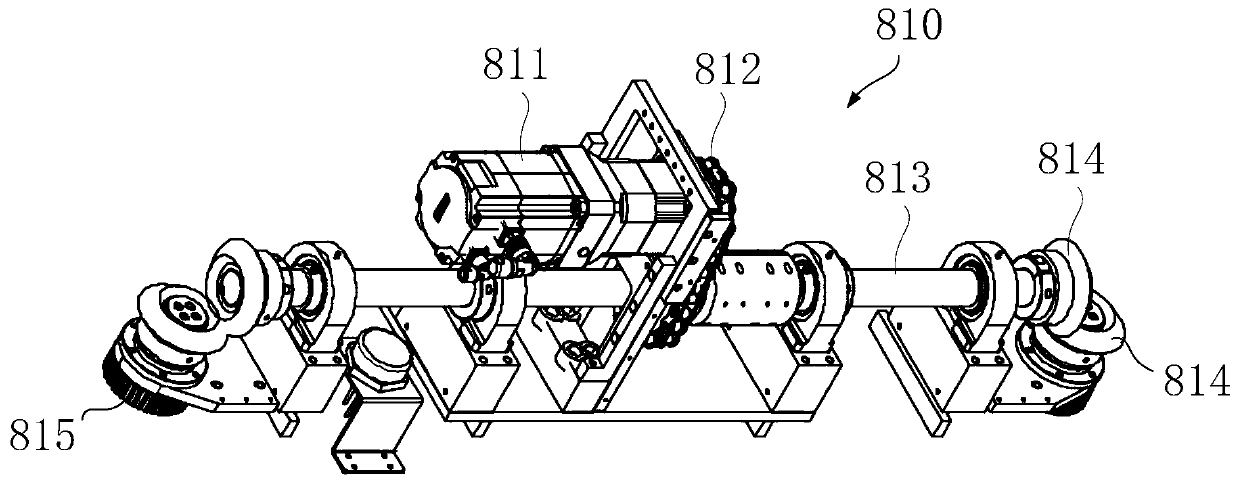

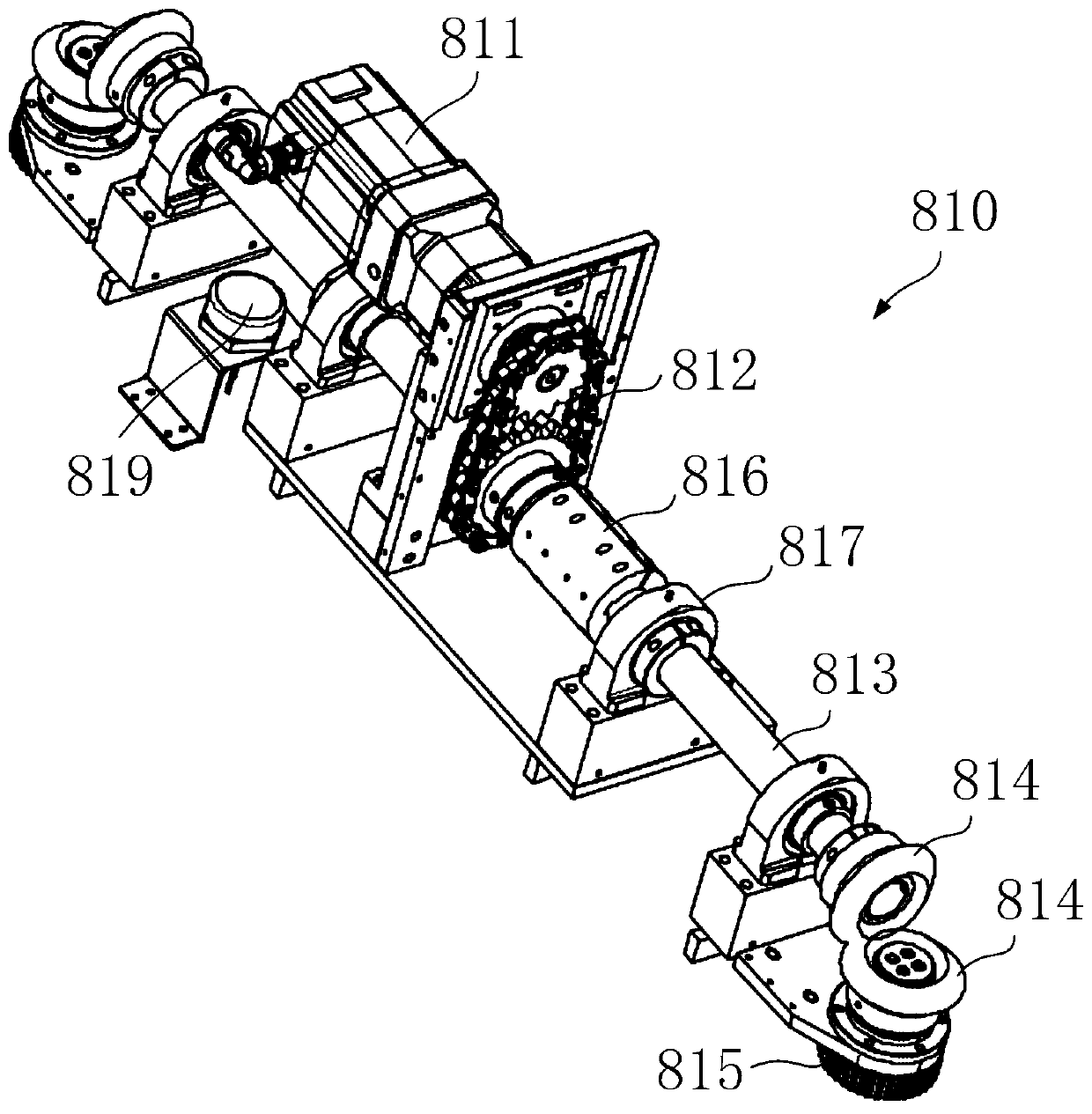

[0056] Embodiment 1. Laterally transfer the main body 810:

[0057] like figure 2 , image 3 As shown, the lateral transfer body 810 includes a lateral driving member 811, a transmission shaft 813, a reversing structure 814, and a driving gear 815; wherein,

[0058] The horizontal driving member 811 drives the transmission shaft 813 to rotate; the transmission shaft 813 is installed perpendicular to the direction of the track 8103; the end of the transmission shaft 813 is connected to the reversing structure 814; The gear 815 rotates, and the driving gear 815 rotating shaft is vertical to the motion direction of the lifting platform body 840; the driving gear 815 is in motion with the rack 818 provided on the direction of the moving track of the drive transfer assembly 800; driven by the transverse driving member 811, so that The driving gear 815 drives the lifting platform body 840 to reciprocate relative to the rack 818 along the track 8103 . In this embodiment, the late...

Embodiment 2

[0066] Embodiment 2, lifting platform body 840:

[0067] like Figure 4-Figure 9 As shown, the lifting platform body 840 includes a first placement plate 841, a second placement plate 842, a lifting drive member, a lifting guide assembly, and a base frame; wherein,

[0068] The first placement plate 841 and the second placement plate 842 are used to limit and carry the battery assembly; in this embodiment, the first placement plate 841 is used to limit the end and side of the battery assembly, and the second placement plate 842 is used to To limit the side of the battery assembly; the first placement plate 841 and the second placement plate 842 are equipped with a "U"-shaped positioning and limiting structure to form the positioning and lifting of the battery assembly.

[0069] The fixed portion of the lifting drive and the lifting guide assembly is fixed on the base frame; the lifting guide assembly is connected to the first placement plate 841 and the second placement plate...

Embodiment 3

[0074] Embodiment 3, floating column body 650 and clamping mechanism body 660:

[0075] like Figure 10-18 As shown, the floating column body 650 connects the fixed substrate and the floating substrate; the clamping mechanism body 660 is installed between the fixed substrate and the floating substrate; wherein;

[0076] The floating column body 650 is used to floatingly support the floating substrate, so that the floating substrate can float up and down and horizontally relative to the fixed substrate;

[0077] The clamping mechanism body 660 is used to fix the floating substrate, so as to counteract the lateral force brought by the floating column body 650 during the power exchange process.

[0078] In this embodiment, combining 10, Figure 11 As shown, the floating substrate is the first placement plate 841 , and the fixed substrate is the first fixed plate 847 . In one embodiment, combined with Figure 10-Figure 14 As shown, the floating substrate includes a first float...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com