Patents

Literature

131results about How to "Eliminate lateral force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

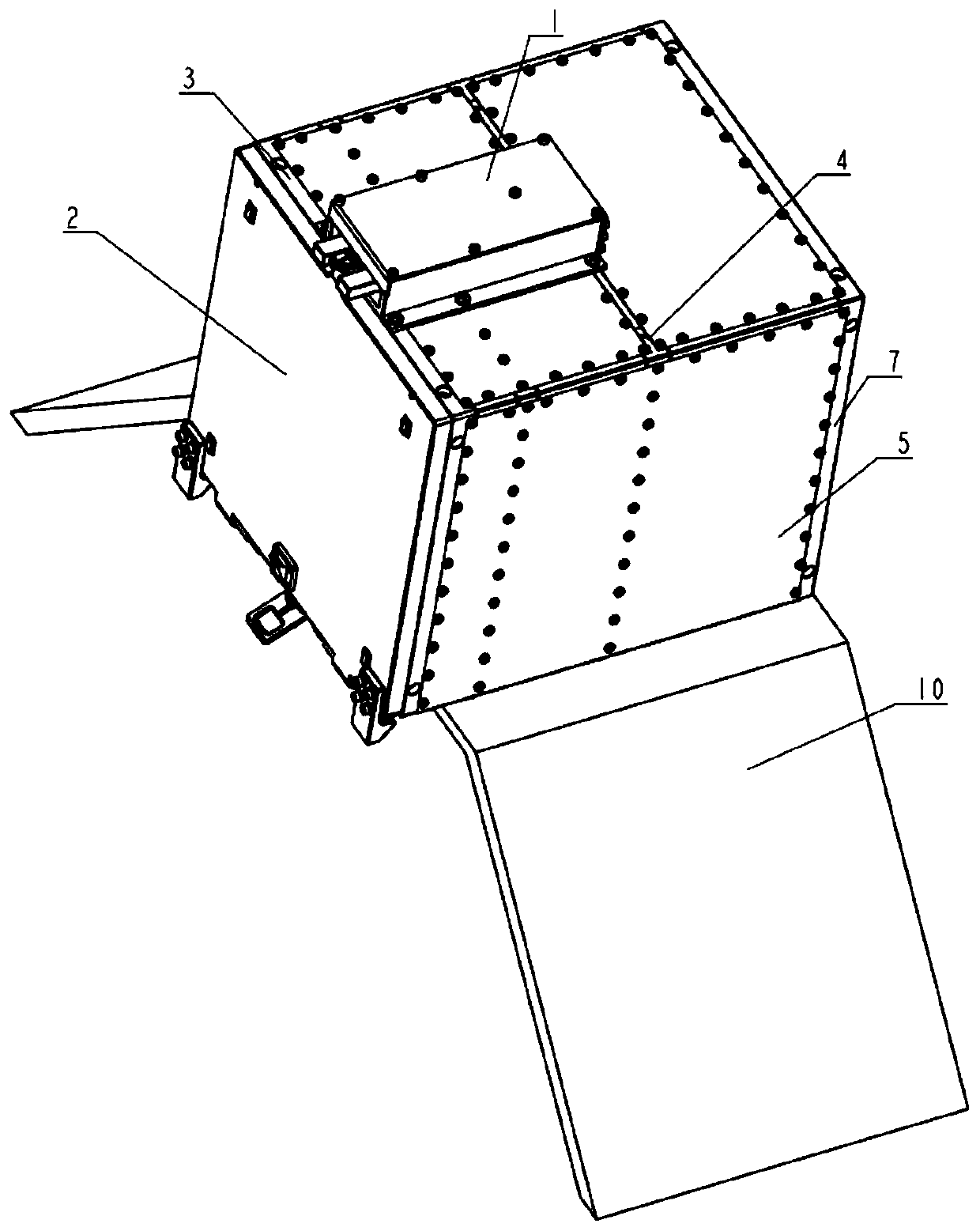

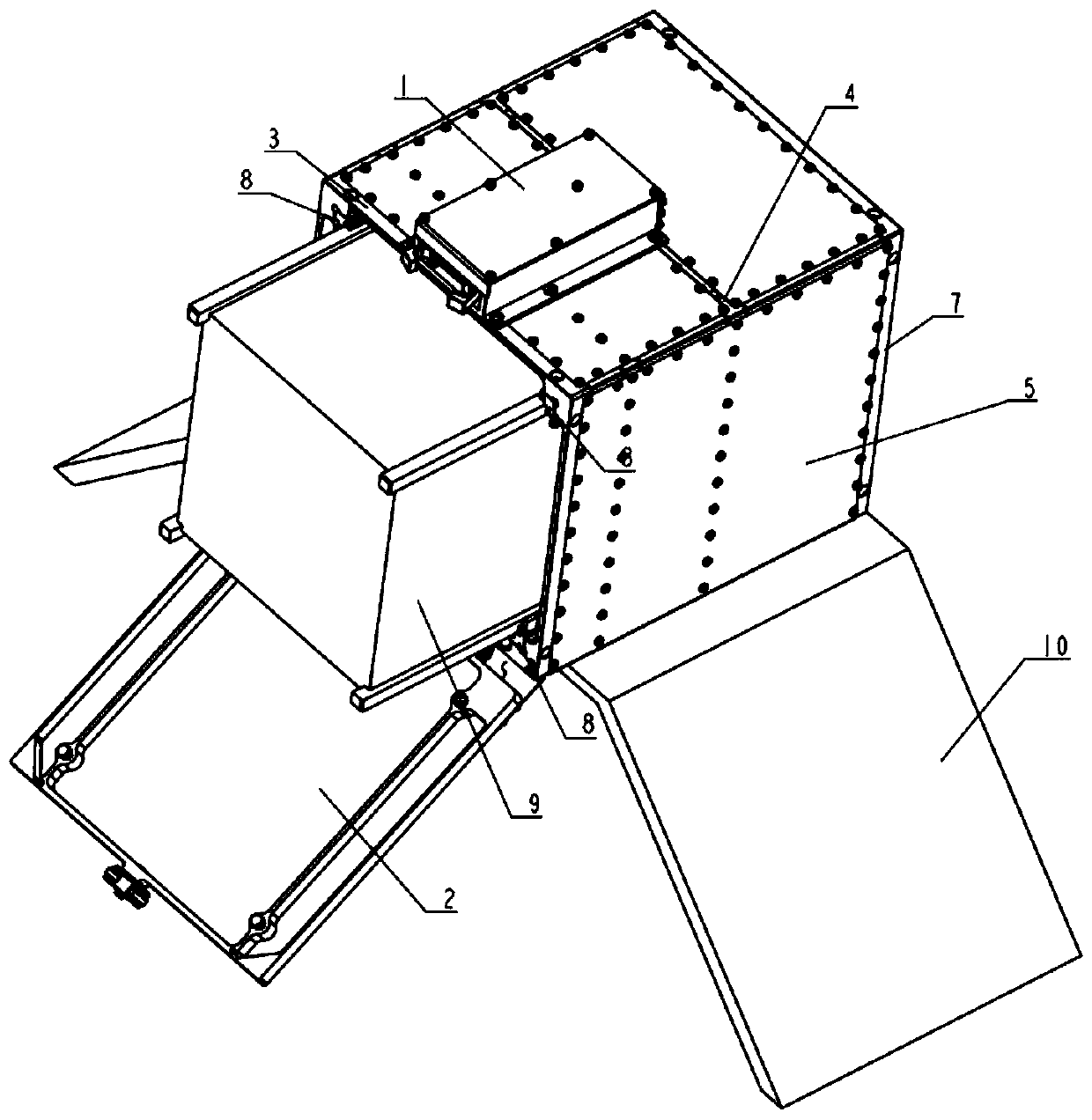

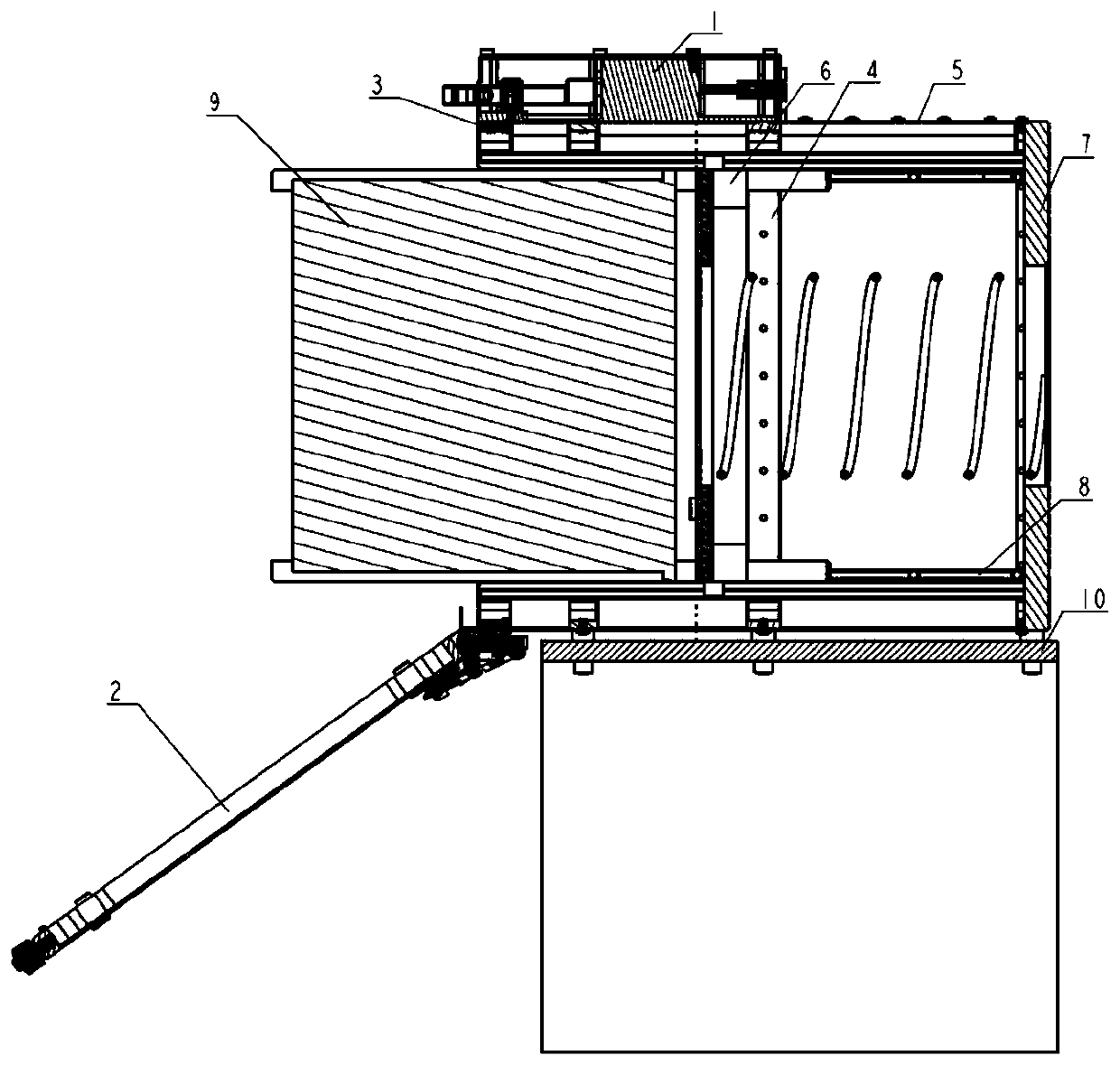

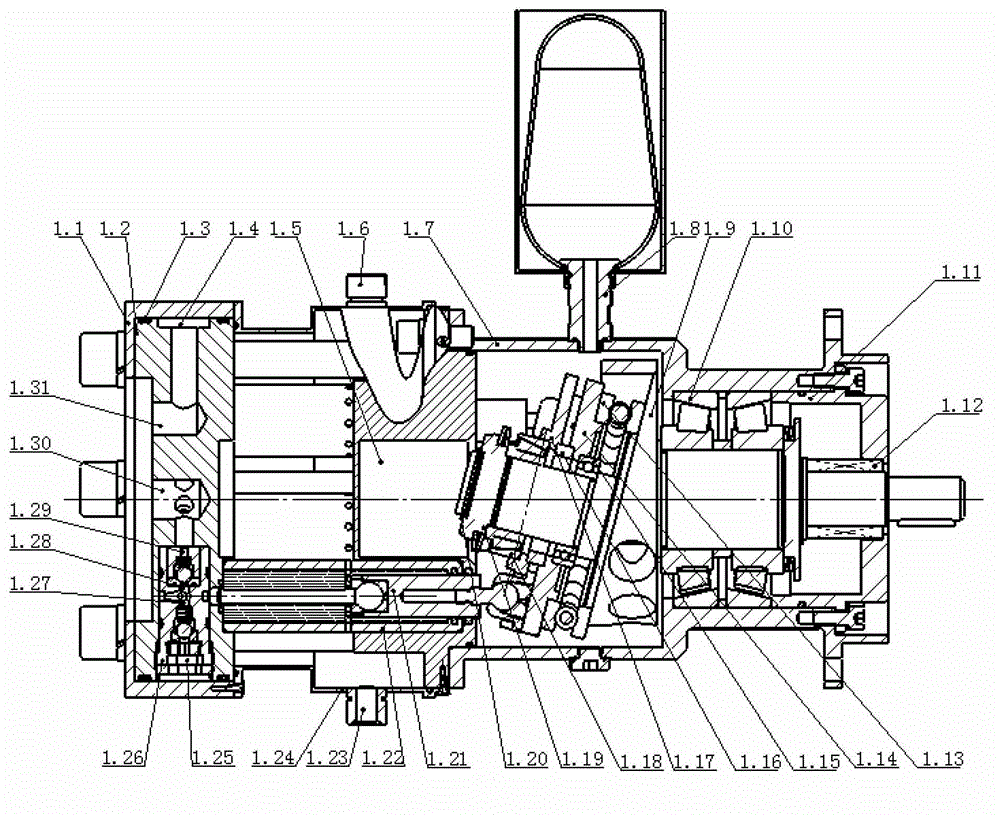

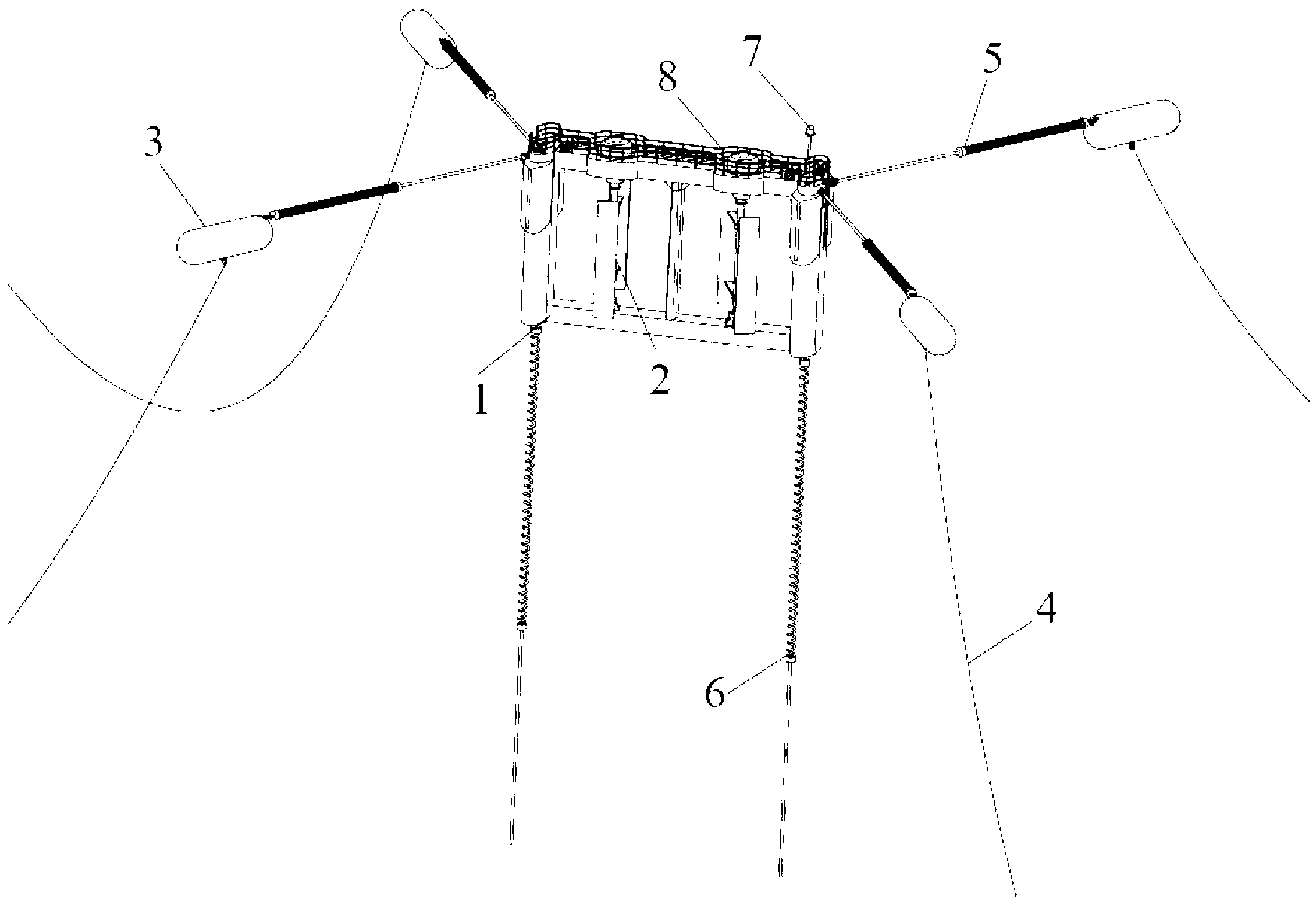

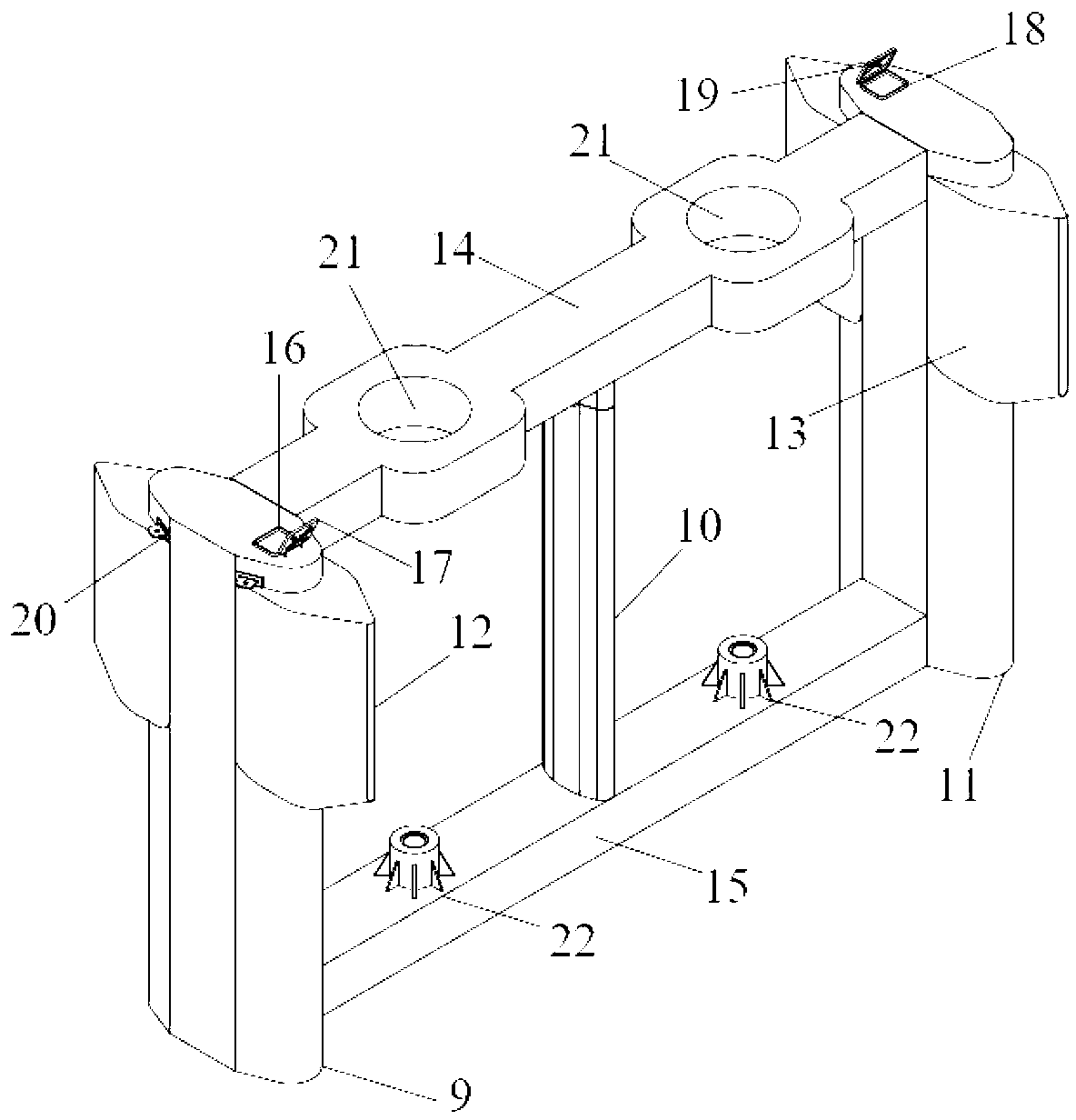

Cubic satellite releasing device

ActiveCN110282162AAchieve unlockImprove reliabilityCosmonautic vehiclesCosmonautic component separationEngineeringMechanical engineering

A cubic satellite releasing device comprises a cabin locking and unlocking mechanism, a cabin door, a front frame component, a middle frame component, a side skin component, a push plate component, a bottom plate and a guide rail component. The front frame component, the middle frame component, the bottom plate and the guide rail component form a frame; the bottom plate is mounted on an aircraft mounting bracket; the guide rail component is mounted on the bottom plate; the front frame component and the middle frame component are fixed on the guide rail component; the side skin component coats the exterior of the frame; and the push plate component is positioned in the frame, is in sliding fit with the guide rail component and is in contact with the bottom plate through a spring. The cabin door is mounted on the front frame component and can rotate around a shaft on the front frame component; the cabin locking and unlocking mechanism is mounted on the front frame component and the middle frame component; when the cabin door is closed, the cabin locking and unlocking mechanism is used for locking the cabin door; and when a separating instruction is received, the cabin locking and unlocking mechanism releases restriction to the cabin door to open the cabin door. The cubic satellite releasing device has the advantages that reliable releasing can be realized, the cabin door can be reliably locked and a detection and vibration absorbing function is realized.

Owner:BEIJING INST OF ASTRONAUTICAL SYST ENG +1

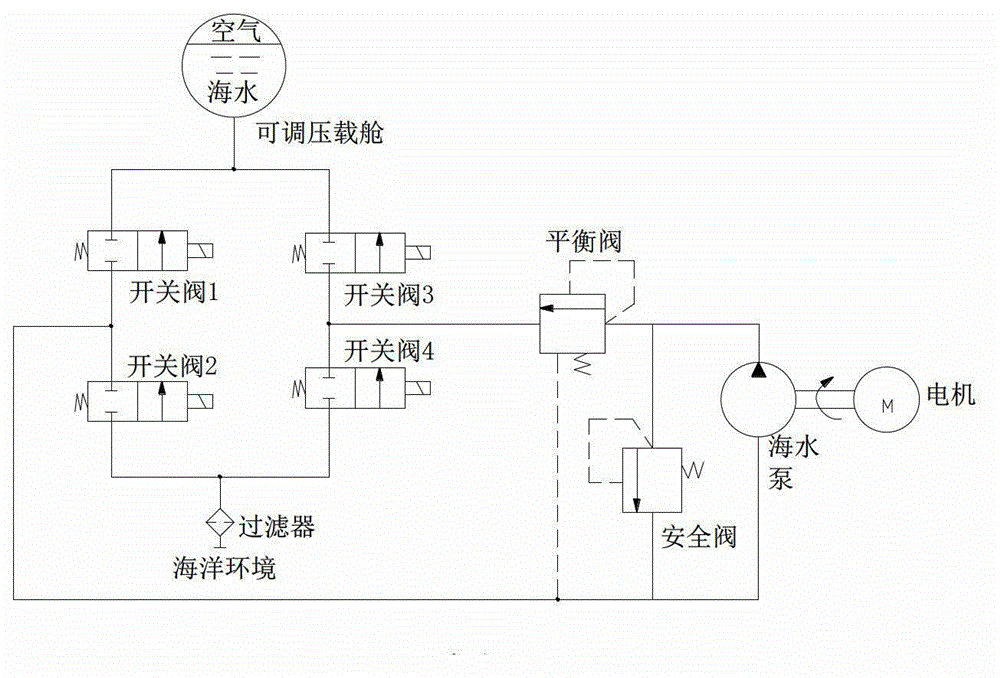

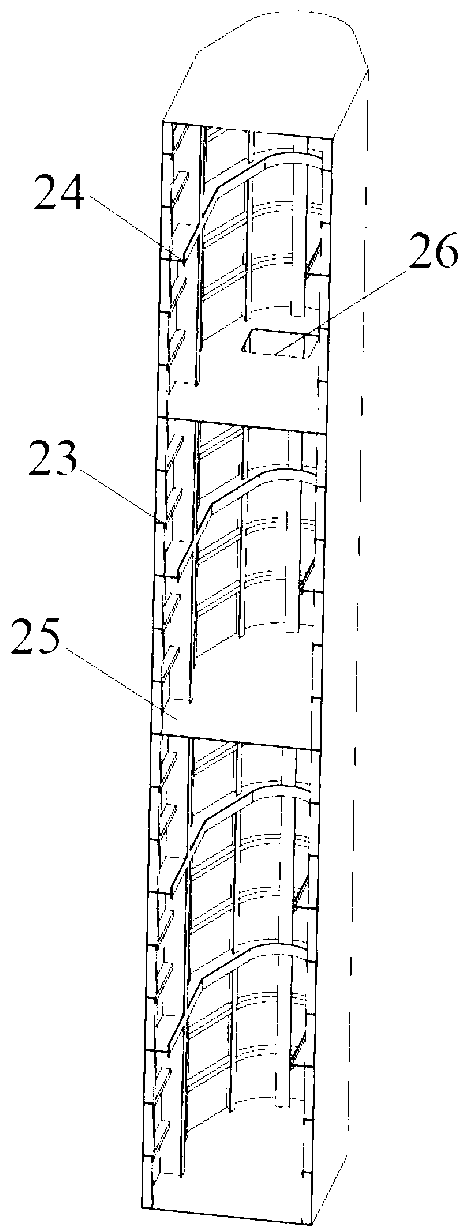

Full depth buoyancy regulating seawater pump

ActiveCN102720648ASolve dynamic sealing problemsSolve pressurePositive-displacement liquid enginesMulti-cylinder pumpsStrength designUltimate tensile strength

The invention discloses a full depth buoyancy regulating seawater pump, which mainly comprises a flat valve module, a plunger piston shoe module, a plunger sleeve, a force transfer and reset mechanism and a pressure compensator, wherein the pressure compensator is used for balancing a lubricating cavity and environmental stress; the force transfer and reset mechanism drives the plunger piston shoe module to alternately cycle for a pressing travel and a sucking travel, so that the flat valve module alternately cyclically sucks water and presses water; the plunger piston shoe module has a fixed interval forced reset structure, so that a plunger is reset reliably; the force transfer and reset mechanism has a bidirectional stress structural design, so that the seawater pump meets the special working condition of regulating the buoyancy by the hydraulic pressure of seawater; and a stepped plunger is adopted, large and small plungers are connected through a spherical hinge, and the problems of strength design, sealing and frictional wear of the crucial friction pair, namely an ultrahigh pressure seawater pump are solved. The full depth buoyancy regulating seawater pump can regulate the buoyancy of a submersible in sea areas with all depth, and has the characteristics of simple structure, high applicability and working reliability.

Owner:HUAZHONG UNIV OF SCI & TECH

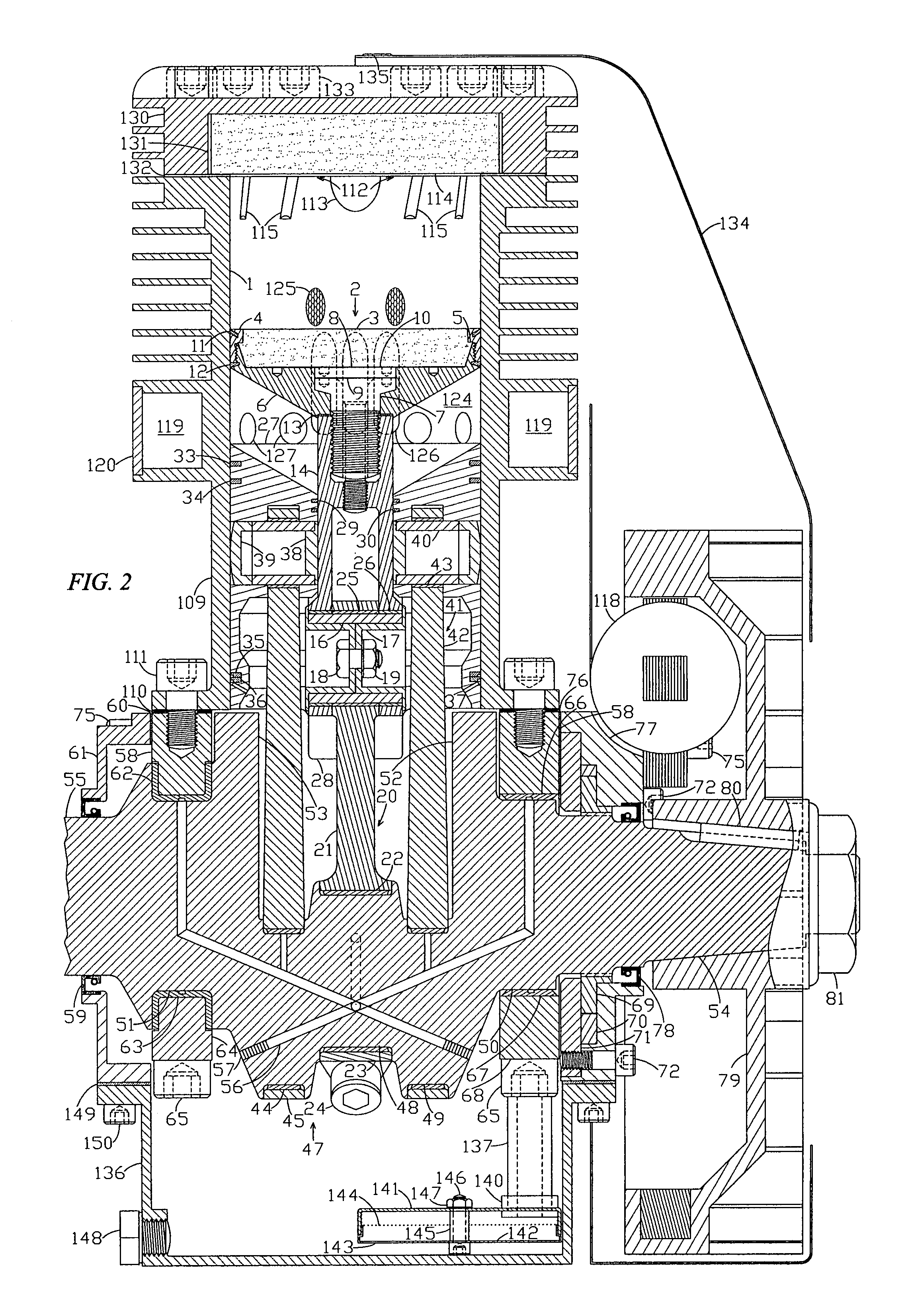

Tandem-piston engine

InactiveUS7389755B2Reduction factorReduce lossesCombustion enginesPistonsPiston ringThermal expansion

Owner:NOLAND RONALD DEAN

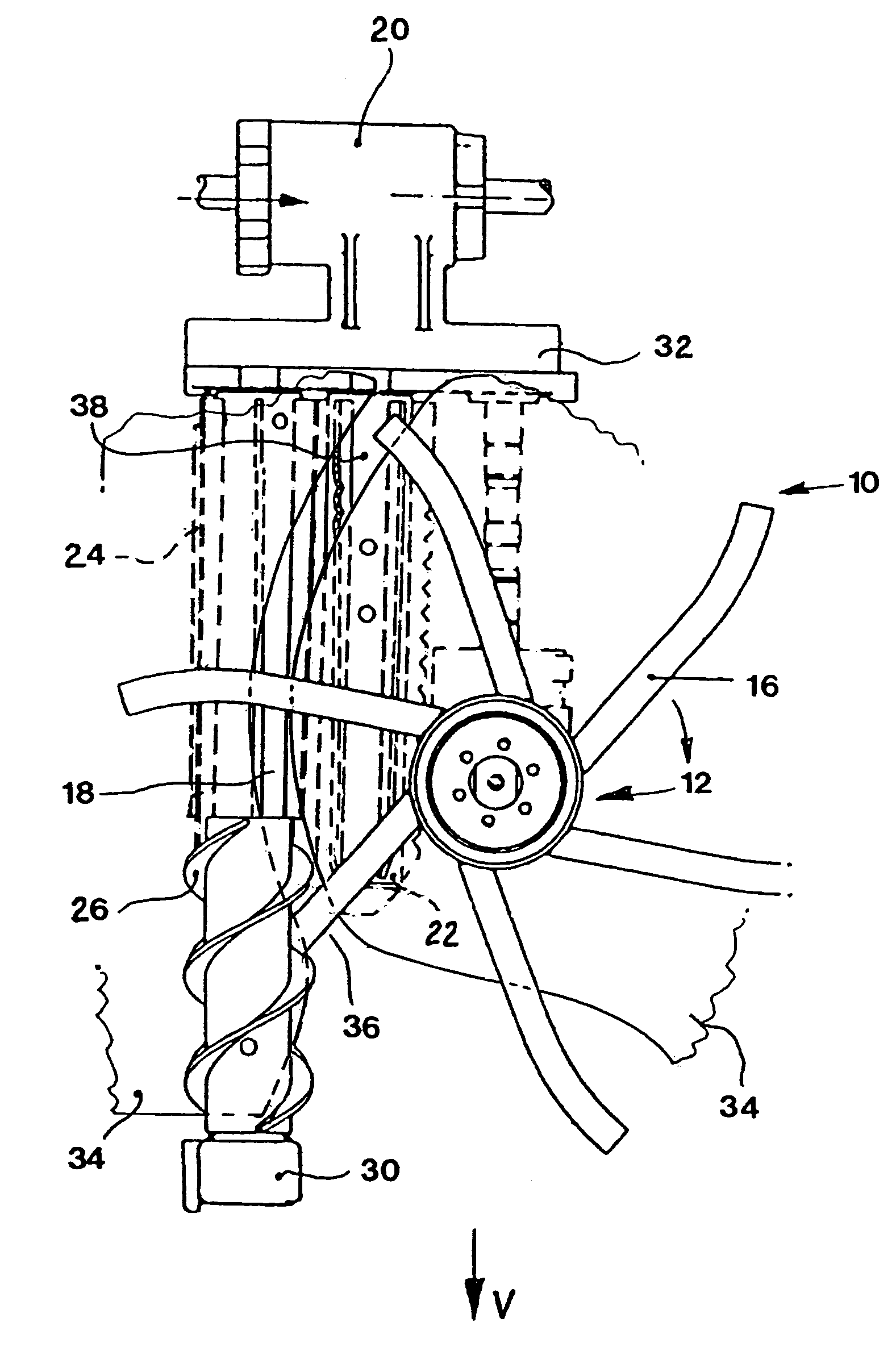

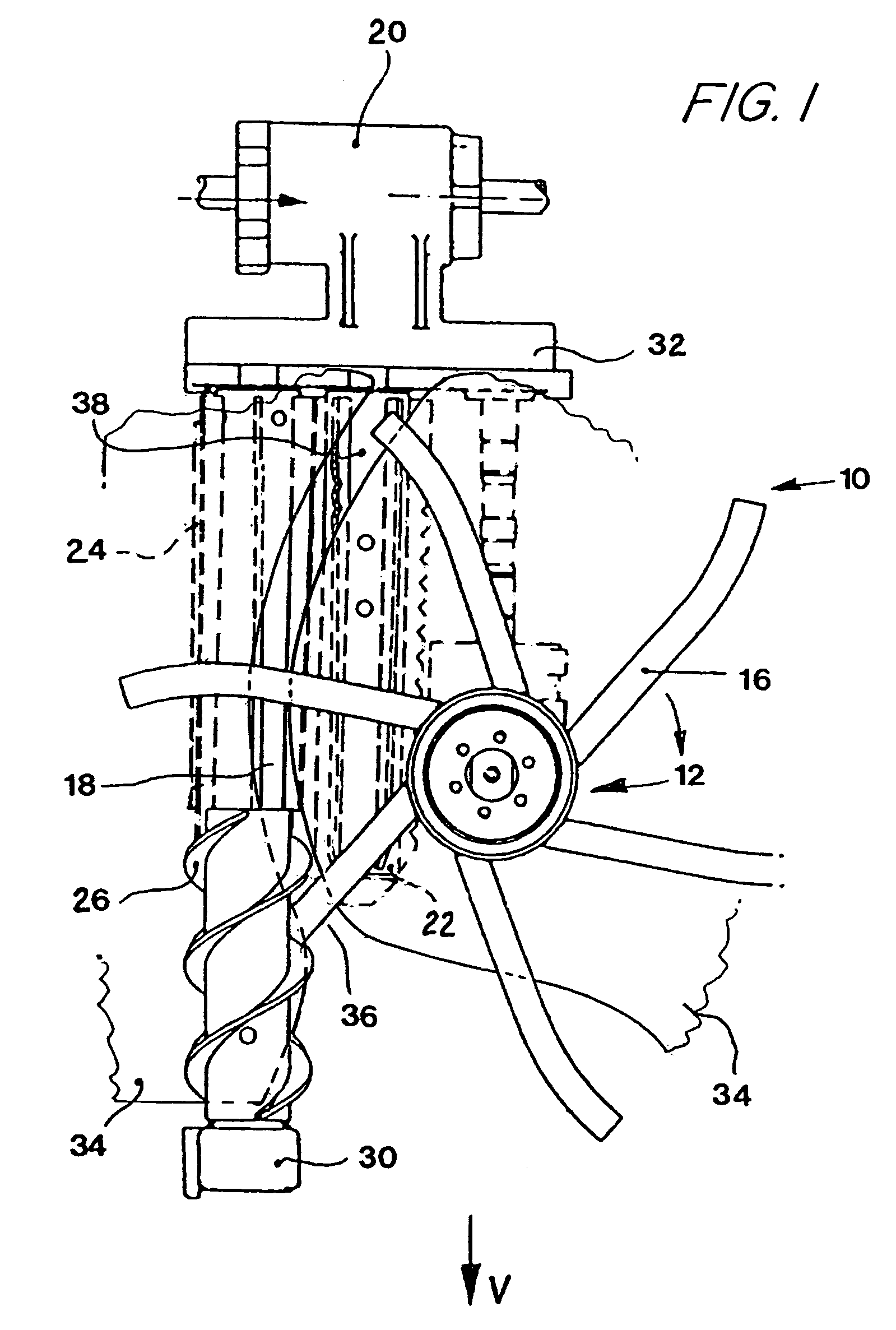

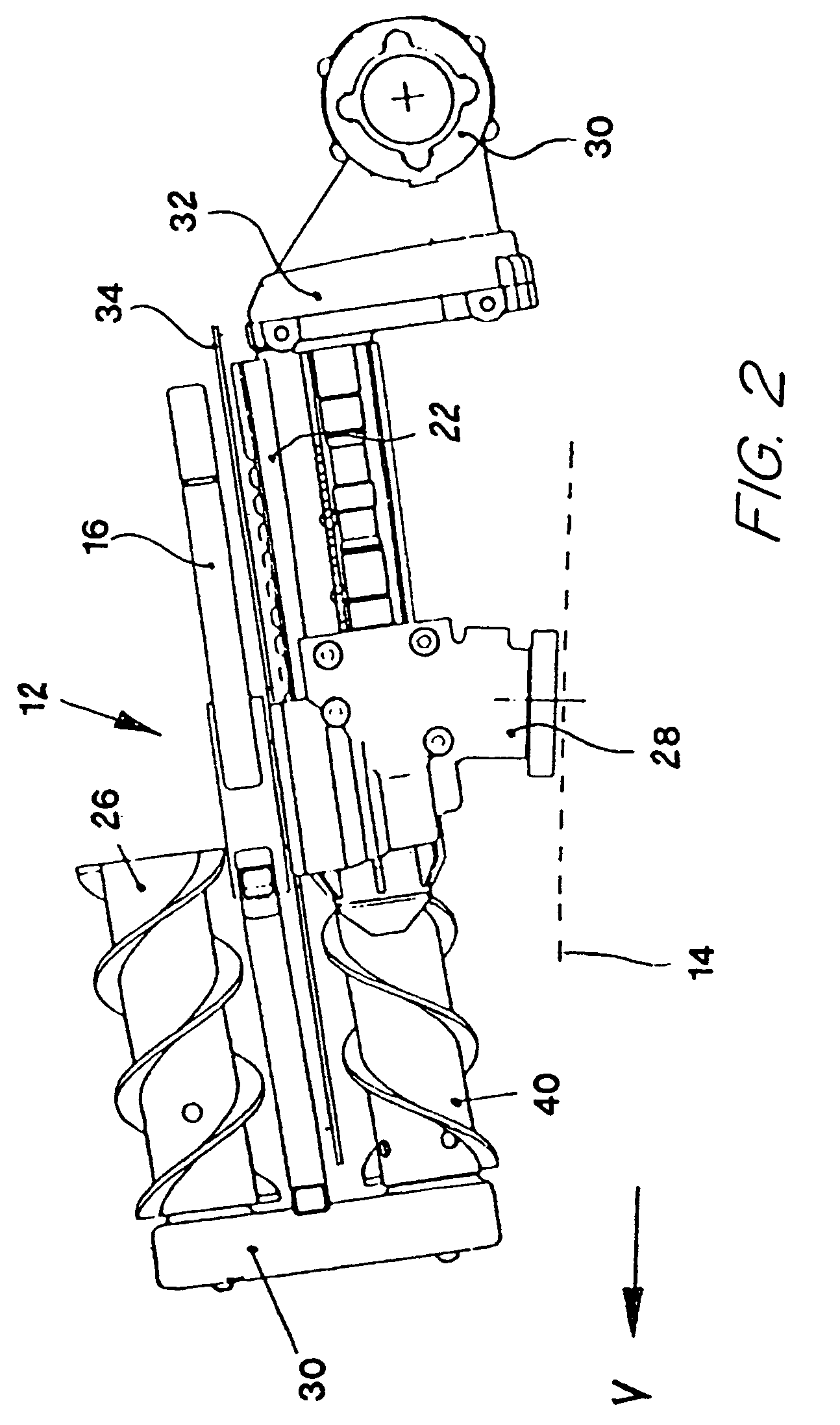

Gathering and picking device having a curved picking gap

A gathering and picking device having a gathering element having radially extending fingers is rotated about an approximately vertical axis. The fingers are arranged to grasp plant stalks and transport the plant stalks along a picking gap of a picking device. The picking gap is curved such that it maintains an at least approximately constant distance from the vertical rotational axis of the gathering element over its operative length.

Owner:MASCHFAB KEMPER

Energy-saving vehicle braking device and method

InactiveCN106143438AReduce wastePrevent slippingBraking element arrangementsWheel speed sensorDrive shaft

The invention provides an energy-saving vehicle braking device and method. The device comprises a transmission part, an output and input part and an accessory part, wherein the transmission part comprises a sun gear, a planetary gear, an inner gear, a power gear, a semi-axle shaft sleeve, a brake drum, a brake synchronizer, a release synchronizer, a front bearing and a rear bearing; the output and input part comprises a transmission shaft, an output and input gear, a transmission shaft front bearing, a transmission oil seal, an output and input gear key, a flat gasket, an output and input gear bolt, a front cover and a brake drum oil seal; the accessory part comprises a casing supporting a half shaft and a Hall wheel speed sensor. The energy-saving vehicle braking device is reasonable in structure design and is safe and reliable to use, the problems of energy waste, danger and high probability of damage to tires and pavements of an existing braking device adopting the friction principle are fundamentally solved, most energy in the braking process can be recovered and utilized, the drag slip and sideslip phenomena of a vehicle are prevented, and traffic safety is ensured.

Owner:王刚

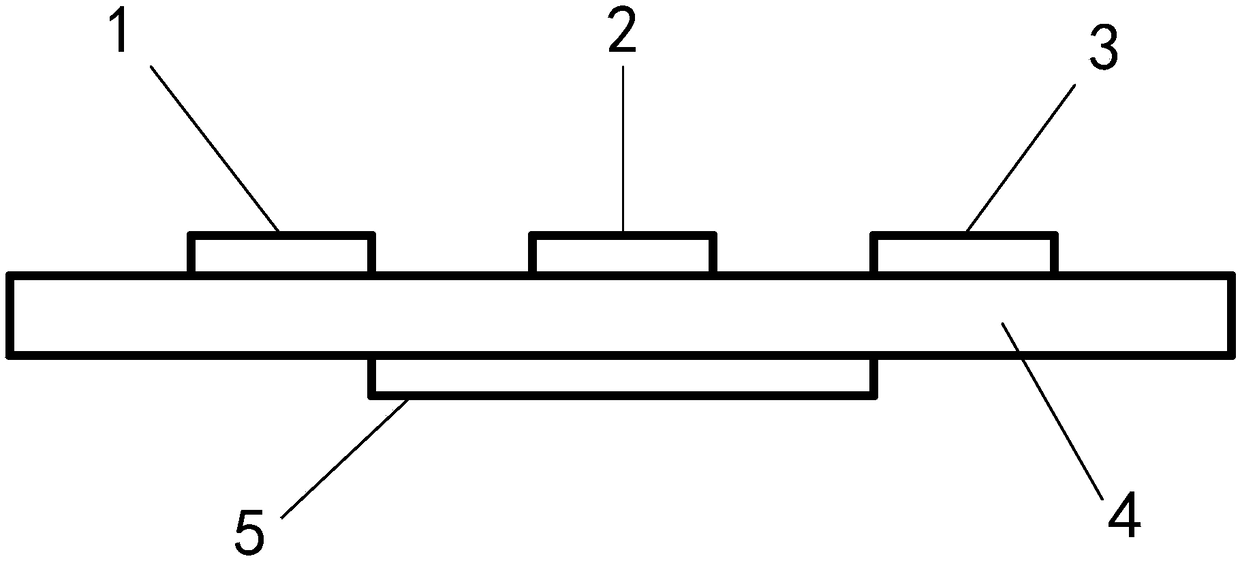

Sliding discharge exciter and plasma flow control method thereof on slender body

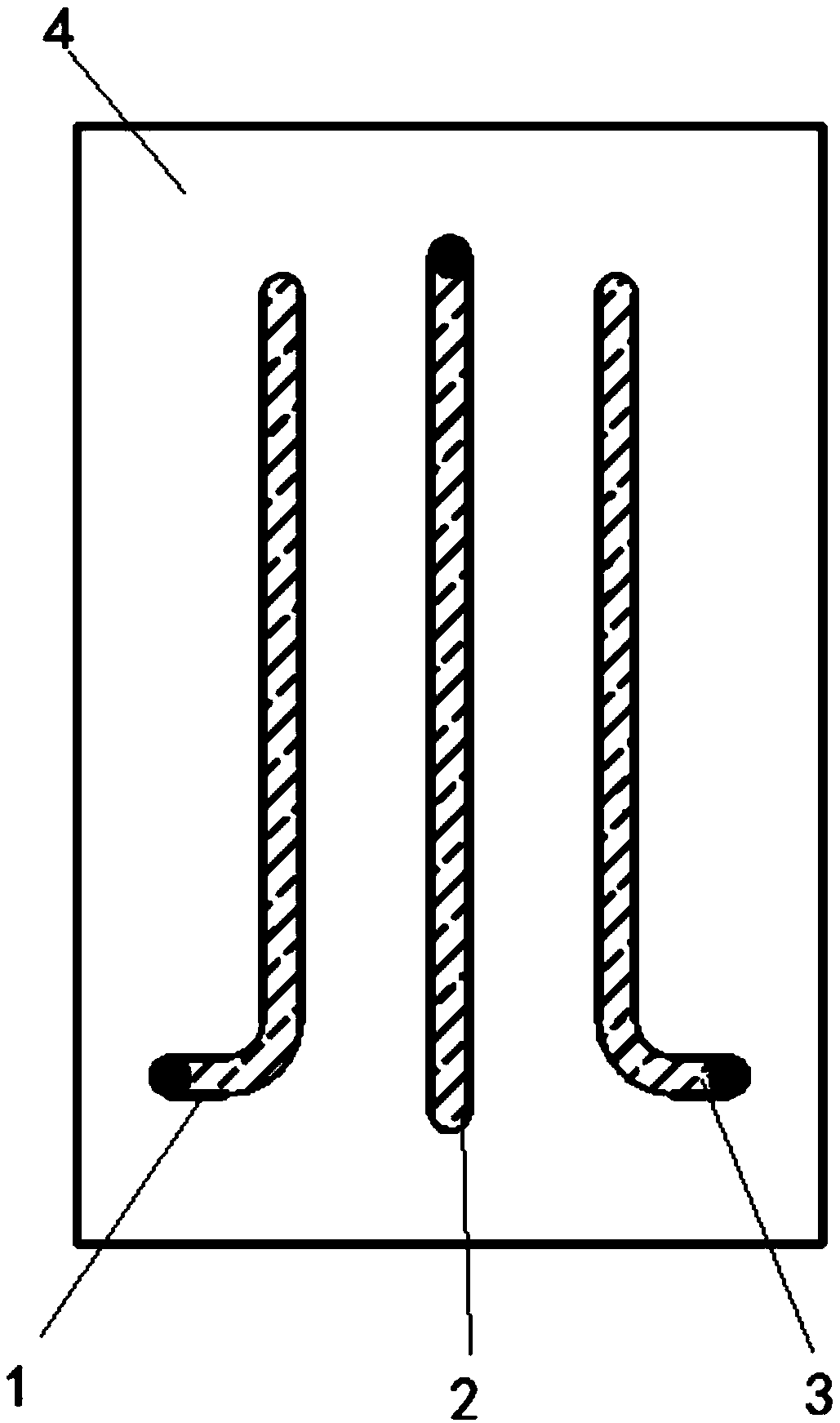

InactiveCN108235553ASimple structureLight in massAircraft controlPlasma techniqueNon symmetricMedia layer

The invention discloses a sliding discharge exciter which comprises an insulating medium layer, wherein a lower electrode layer is arranged on the lower bottom surface of the insulating medium layer;a first upper electrode, a second upper electrode and a third upper electrode are arranged on the upper surface of the insulating medium layer; the first upper electrode and the third upper electrodeare positioned on two sides of the second upper electrode respectively; a positive pulse high voltage VNP is applied to the second upper electrode; and a direct-current high voltage VDC1 and a direct-current high voltage VDC2 are applied to the first upper electrode and the third upper electrode respectively. The sliding discharge exciter disclosed by the invention can generate stable and uniformlarge-range sliding plasma discharge so as to control an asymmetric vortex structure when the slender body has a large attack angle, and eliminate lateral force. In the slender body plasma flow control method, through pressure measurement, flow display and other measurement means, the evolution characteristics of asymmetric separation flow of the flow around the back of the slender body in different flow states are understood, and the excitation parameters are adjusted as required so as to realize control on the asymmetric vortex of the slender body in a wide flow range.

Owner:XIAN UNIV OF TECH

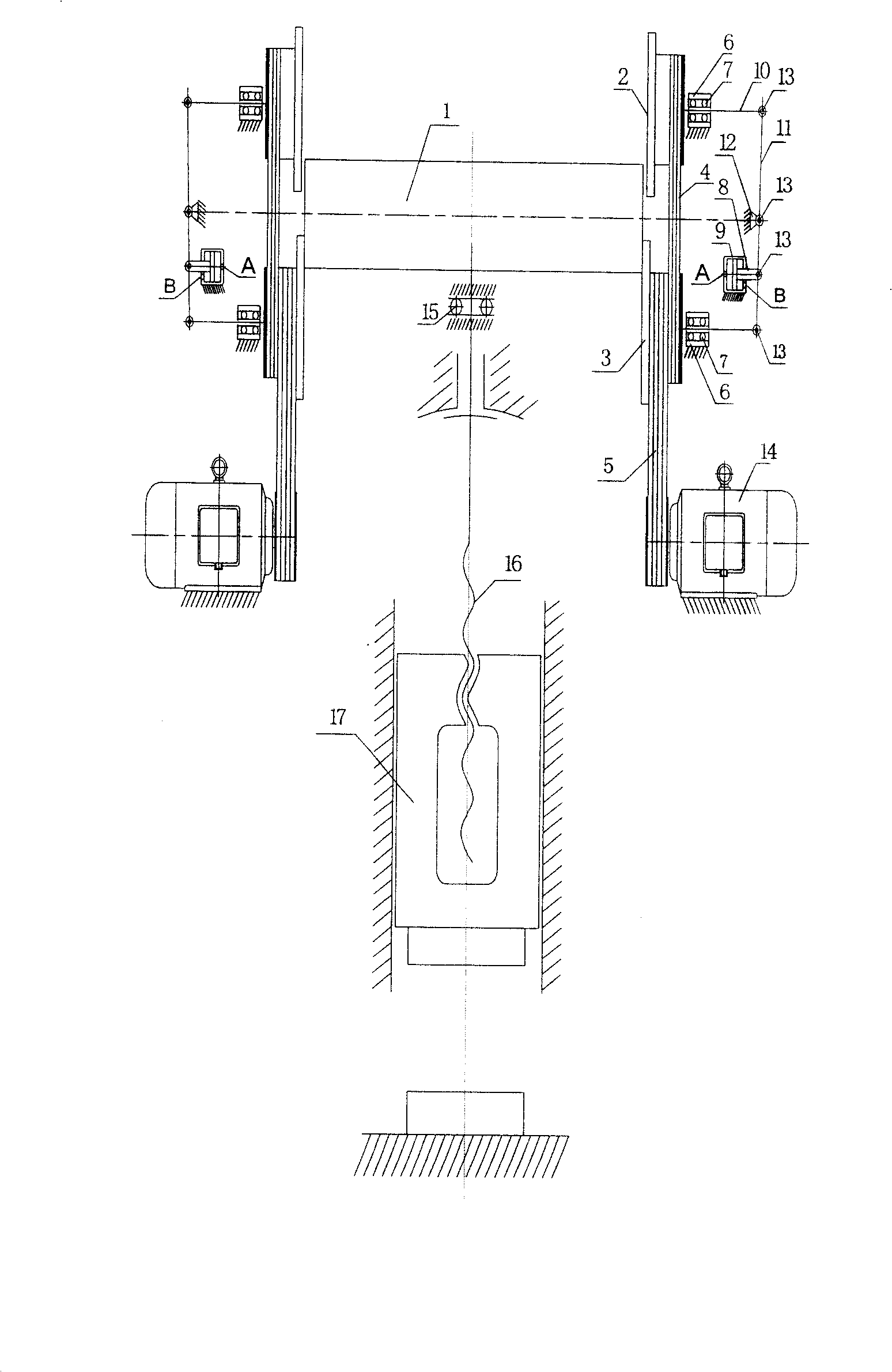

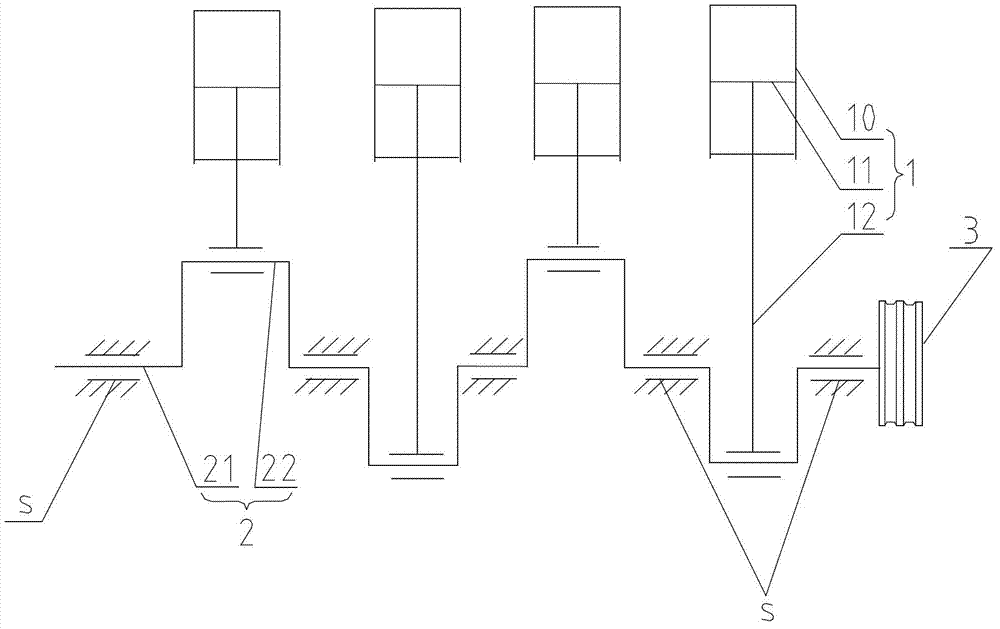

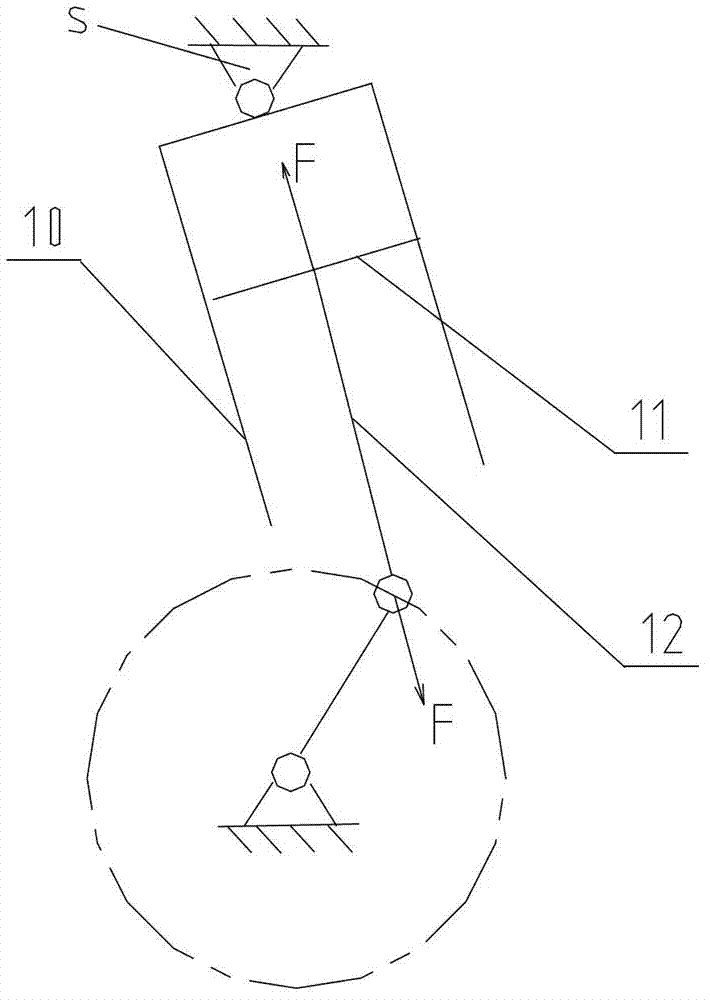

Straight-line reciprocating piston type compressor

ActiveCN101560968AReliable transmissionReduce vibrationMulti-stage pumpsPositive-displacement liquid enginesLow noiseReliable transmission

The invention discloses a structure of a straight-line reciprocating piston type compressor. The connecting mode between a crankshaft and a power transmission part of a piston rod is as follows: the crankshaft is sleeved with a sliding block; the sliding block and the power transmission part are pressed or tightened by a tension spring, a spring reed or a spring; or based on the connection, rolling bodies of rolling needles, or rolling balls and the like, or other sliding bodies with low friction coefficient are arranged between the sliding block and the power transmission part; or the crankshaft is sleeved with a bearing; the bearing and the power transmission part are pressed or tightened by a tension spring, a spring reed or a spring; or the crankshaft is sleeved with the sliding block;the contact surface of the sliding block and the power transmission part is provided with a guide rail; and the power transmission part is arranged in the guide rail and can move in the guide rail ina reciprocating way. The structure of the straight-line reciprocating piston type compressor has the following advantages that: (1) the zero gap transmission is realized between the crankshaft and the piston rod, the equipment has little friction force, little vibration, low noise and accurate and reliable transmission; (2) a plurality of cylinders can be arranged for exhausting when the piston type compressor rotates by one circle, thus greatly improving the work efficiency of the motor and being suitable for being applied in the transmission structure of the piston type compressor.

Owner:ZHEJIANG HONGYOU AIR COMPRESSOR MFG

Drive mechanism of four-wheel friction screw press

The invention relates to a driving device of a four-wheel friction screw press, comprising a flywheel rotating horizontally; wherein, the flywheel is connected with a screw; an upper friction wheel and a lower friction wheel driven by a motor are symmetrically positioned on the two sides of the flywheel; four friction wheels rotate in the same direction; the rotating shafts of the upper friction wheel and the lower friction wheel are movably connected with the two ends of a lever by a pin; the lever driven by an oil pressure cylinder swings with the pivot as the center, and controls the upper friction wheel and the lower friction wheel to press and leave the wheel margin of the flywheel alternately; the piston rods of two oil pressure cylinders move towards the middle flywheel; simultaneously, the lower friction wheel presses the inferior margin; the flywheel rotates to the right; a sliding block presses down; the piston rods of two oil pressure cylinders move outwards; simultaneously, the upper friction wheel presses the upper margin of the flywheel; the lower friction wheel leaves the flywheel; the flywheel rotates to the left; the sliding block is lifted. The driving mechanism has the advantages that the friction wheels on the two sides press the flywheel oppositely with the same force in operation, thus eliminating the lateral force borne by the screw; strong forging ability and high productivity can be obtained when the load is increased.

Owner:SHANGHAI YUNLIANG FORGING PRESS

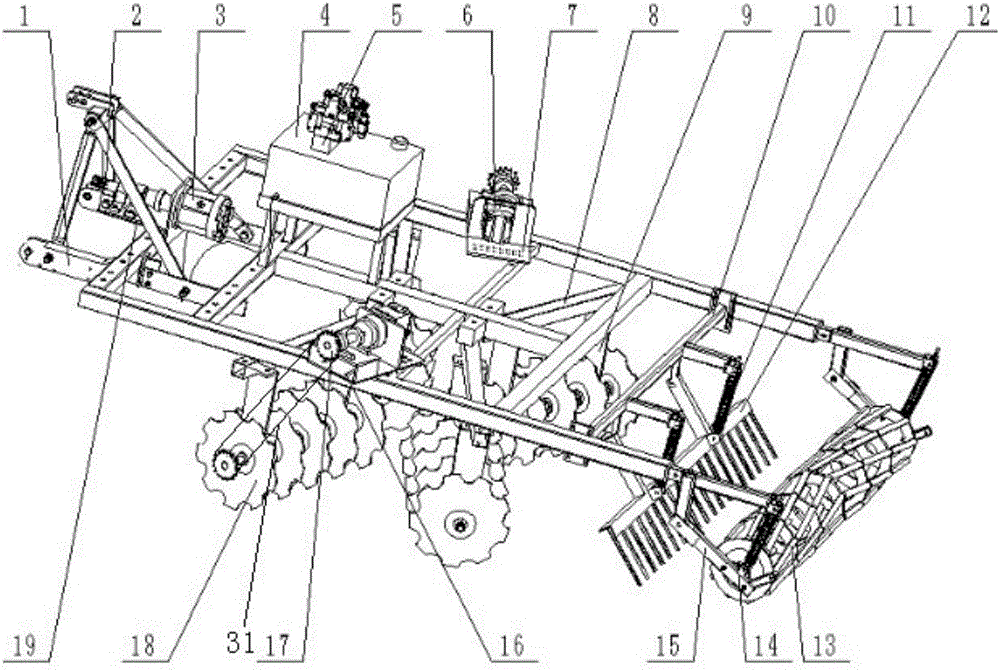

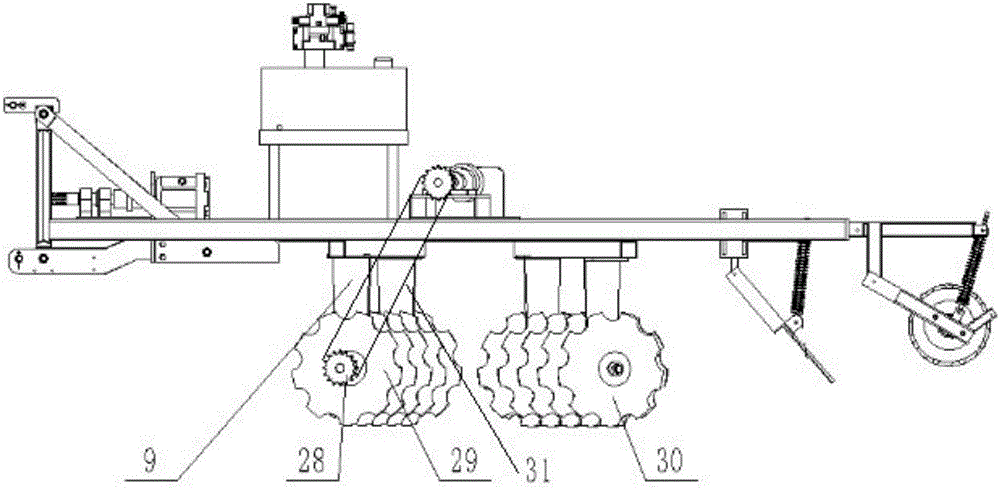

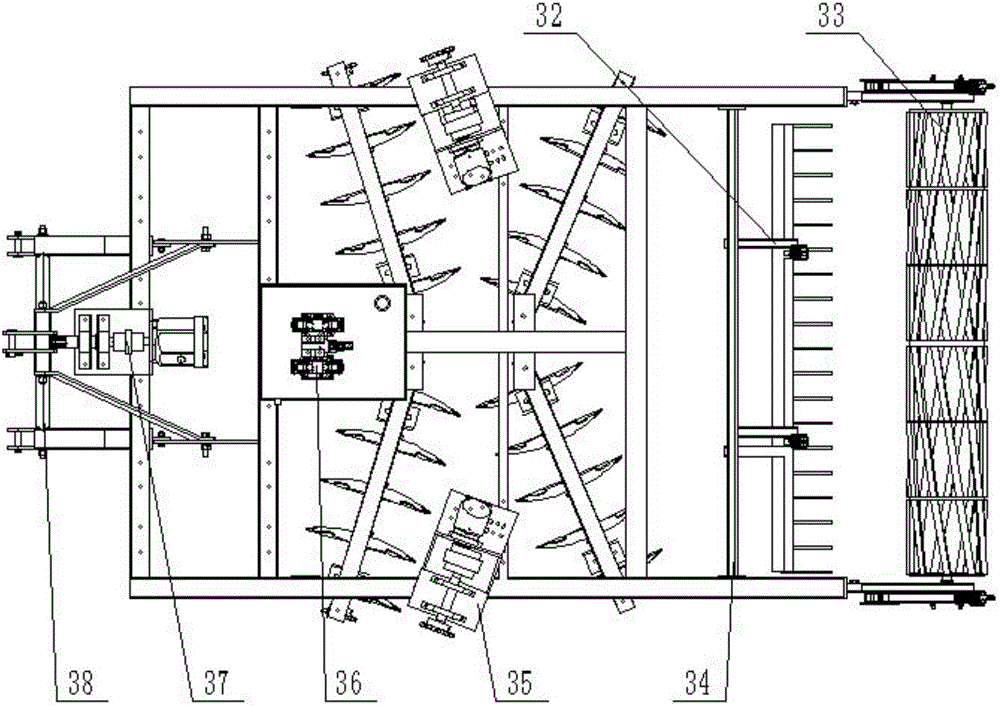

Hydraulic-drive combined land preparation machine

The invention discloses a hydraulic-drive combined land preparation machine, comprising a main frame, a leveling rake unit, a compacting unit, a hydraulic drive unit, a notched disc unit and the like. A suspended hanging mode is used herein, facilitating transporting and turning on the headland; the machine is available for one-time completion of soil loosening, turning, breaking and leveling, is high in operating efficiency and soil breaking rate and is well adaptive to southern lands.

Owner:HUAZHONG AGRI UNIV

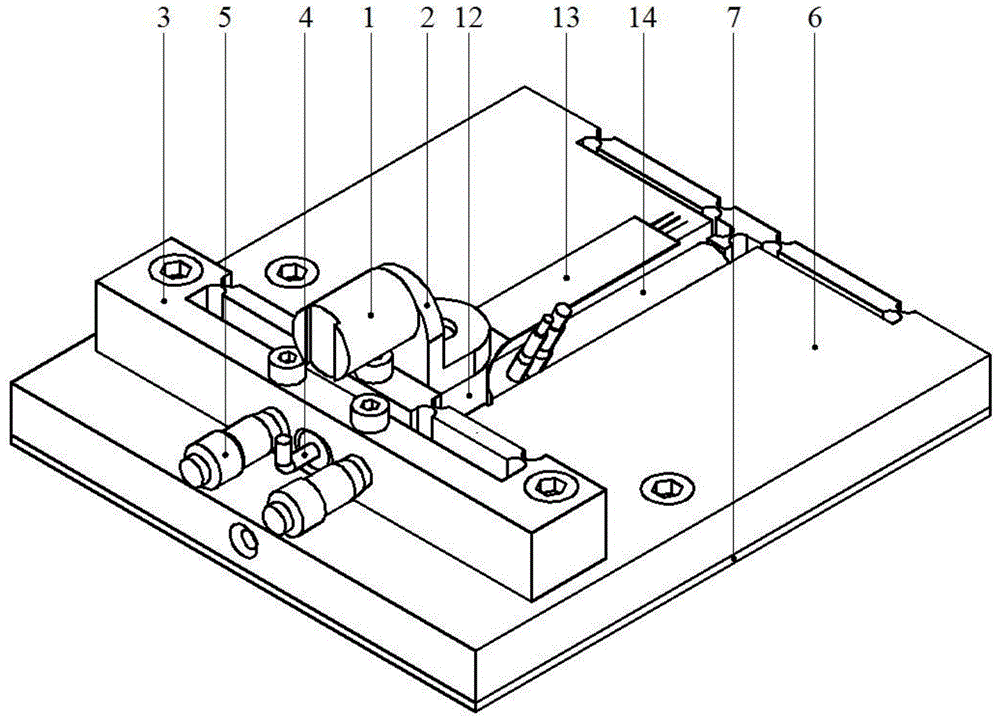

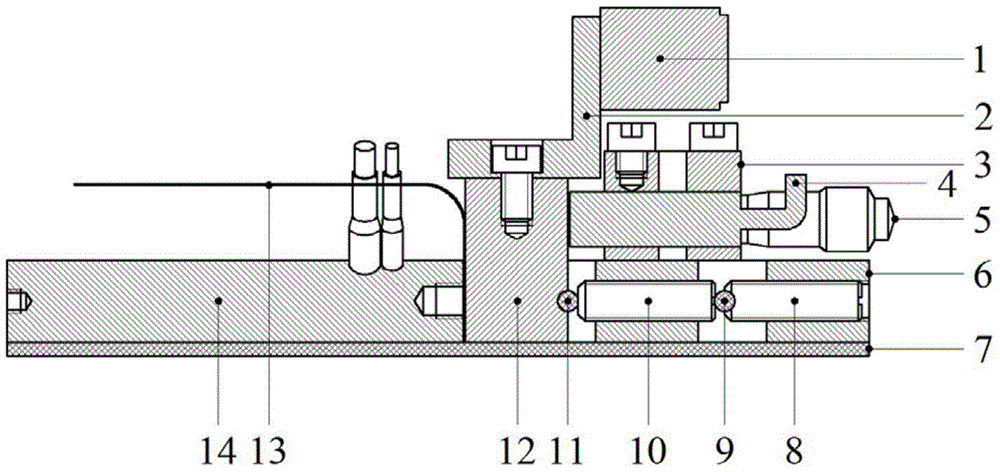

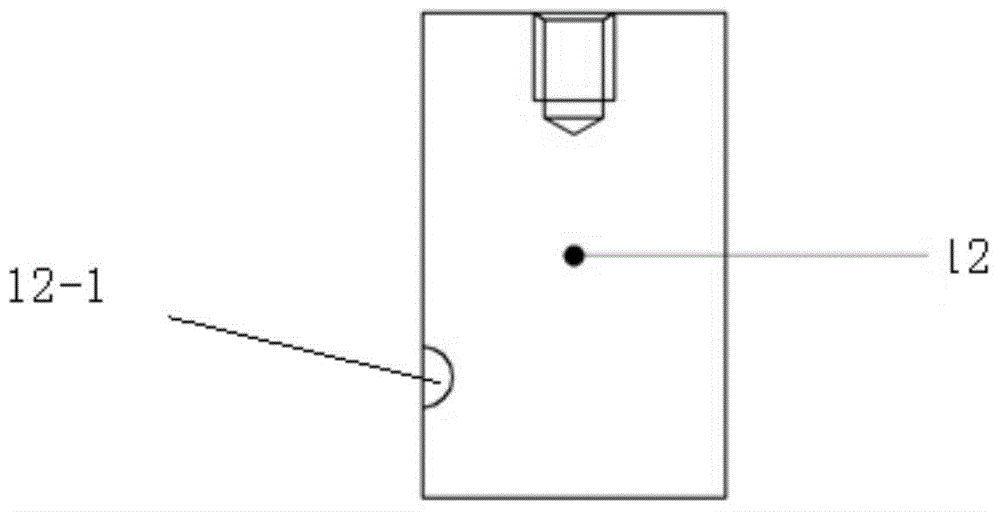

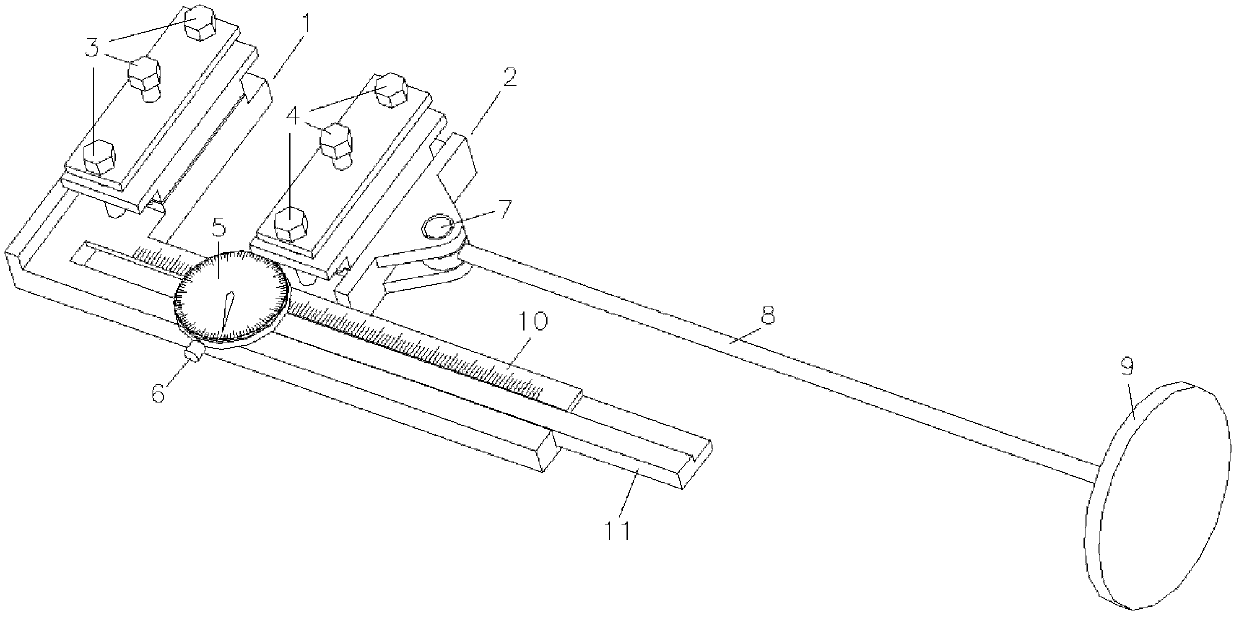

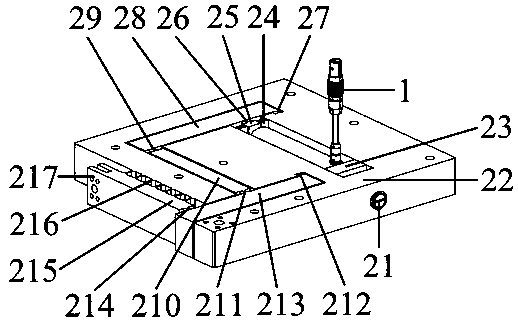

Precision positioning drive-end pre-tightening device

ActiveCN104088871AHigh precisionImprove accuracyAngles/taper measurementsElectric/magnetic position measurementsCapacitive sensingActuator

The invention discloses a precision positioning drive-end pre-tightening device. The precision positioning drive-end pre-tightening device comprises a positioning platform, an actuator, a capacitive sensor, a capacitive sensor support, a pre-tightening block and a thin-film force sensor. A sliding groove is formed in the middle of the positioning platform. The pre-tightening block, the thin-film force sensor and the actuator are sequentially arranged in the sliding groove. The capacitive sensor support is fixed to the positioning platform. Three connecting rods which are sequentially connected with one another through flexible hinges are arranged on one side of a support body of the capacitive sensor support in the axial direction. The end face of the capacitive sensor is parallel to the upper side face of the pre-tightening block, and a gap is formed between the end face of the capacitive sensor and the upper side face of the pre-tightening block. The positioning platform is further provided with a two-stage pre-tightening device for pre-tightening the pre-tightening block. The precision positioning drive-end pre-tightening device can meet the requirements for precision positioning, precision and ultra-precision machining, precision operation and precision measurement and can also meet the requirements of a micro electromechanical system and related fields. The precision positioning drive-end pre-tightening device is simple in technological means and easy to realize, and has outstanding essential characteristics and remarkable progress compared with the prior art.

Owner:SOUTH CHINA UNIV OF TECH

Floating-barrel type tidal current energy generating device

InactiveCN103256170AGuaranteed stabilityReduced motor responseFinal product manufactureHydro energy generationChinese charactersMooring system

The invention provides a floating-barrel type tidal current energy generating device which comprises a mooring system, a carrier and a water turbine / generator set. The floating-barrel type mooring system is used for mooring the carrier provided with the water turbine / generator set. The carrier is of a transversely-arranged door structure, wherein the door is shaped like a Chinese character 'ri'. The carrier comprises a streamline body, a personnel operating platform and a two-line water turbine / generator set support. The water turbine / generator set is used for converting motion energy of tidal currents into electrical energy and formed by connecting a water turbine, a generator and an accessory coaxial line in series. The water turbine / generator set is of a two-line contra-rotating type and is installed inside space of the carrier. The floating-barrel type tidal current energy generating device has the advantages that the floating-barrel type tidal current energy generating device does not need to be carried under a floating-type platform and on a pipe foundation or a tension leg, and therefore yawing force generated when the single-rotor water turbine operates is eliminated. Meanwhile, the generating device is simple in structure, low in production and manufacturing cost, convenient to install and maintain, economical, stable in generating performance, and suitable for being applied to a high sea state environment with rich tidal current energy.

Owner:HARBIN ENG UNIV

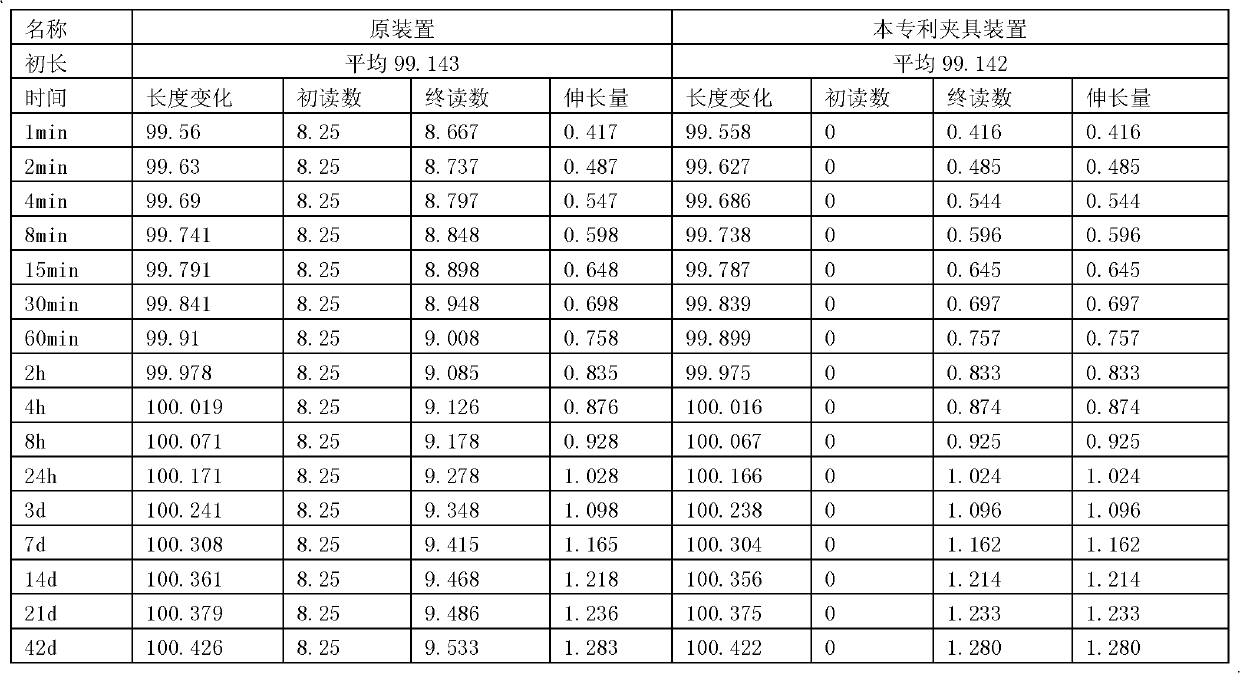

Clamp for measuring creep deformation of geo-grid material, and using method thereof

InactiveCN102607943AEven by forceReduce experimental errorStrength propertiesEngineeringEconomic shortage

The invention relates to a clamp for measuring creep deformation of a geo-grid material, and a using method thereof. The clamp comprises an upper clamp and a lower clamp; the upper clamp and the lower clamp are vertically connected with an outside measuring rule and an inside measuring rule at the same side, respectively; the outside measuring rule and the inside measuring rule are sleeved and slidingly connected; a graduated disc is arranged at the connection part between the inner side measuring rule and the lower clamp; the lower clamp is movably connected with a load rod through a rotating shaft; and the load rod is connected with a tray. According to the invention, the shortage in the existing creep deformation experiment process is avoided, the experimental error is reduced successfully, the stress born by the grid is more uniform, the load application is more normative, the accuracy rate is higher, the experimental error caused by manual factor is greatly avoided, the operation is convenient, the experiment efficiency is enhanced, and the practicality is higher.

Owner:SHANDONG UNIV

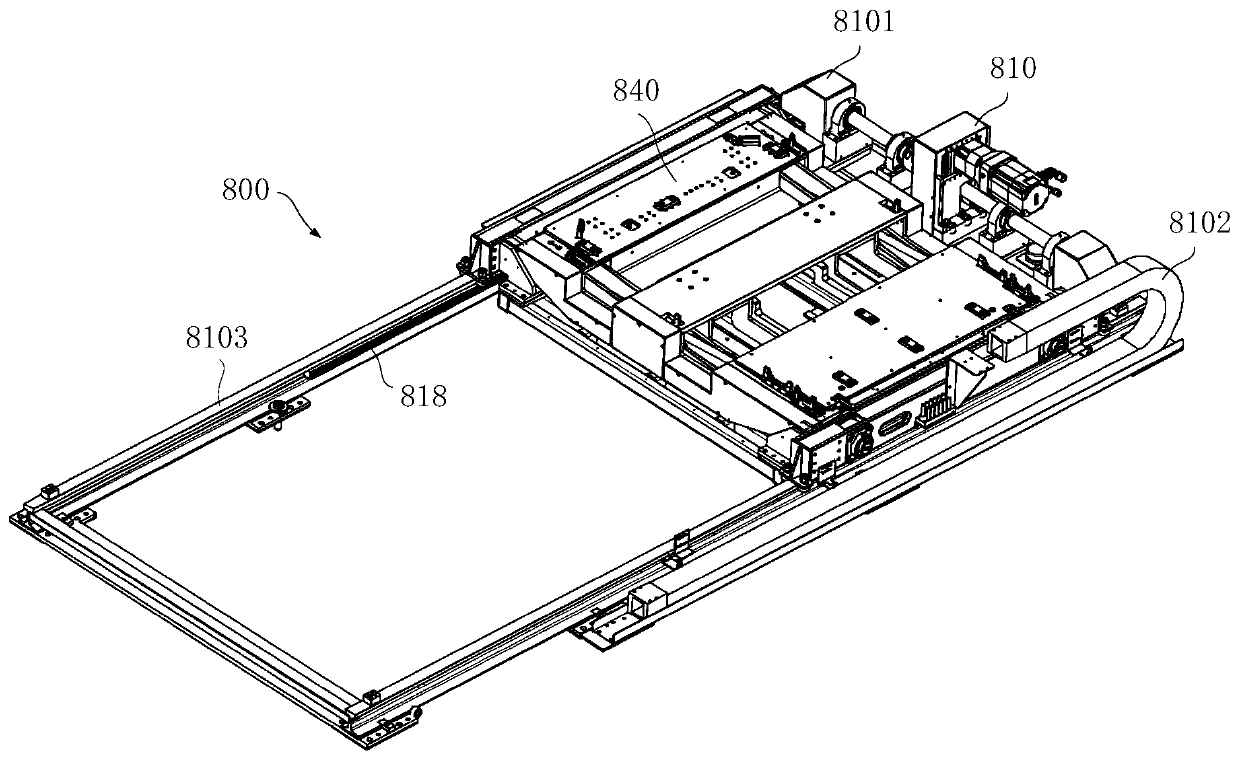

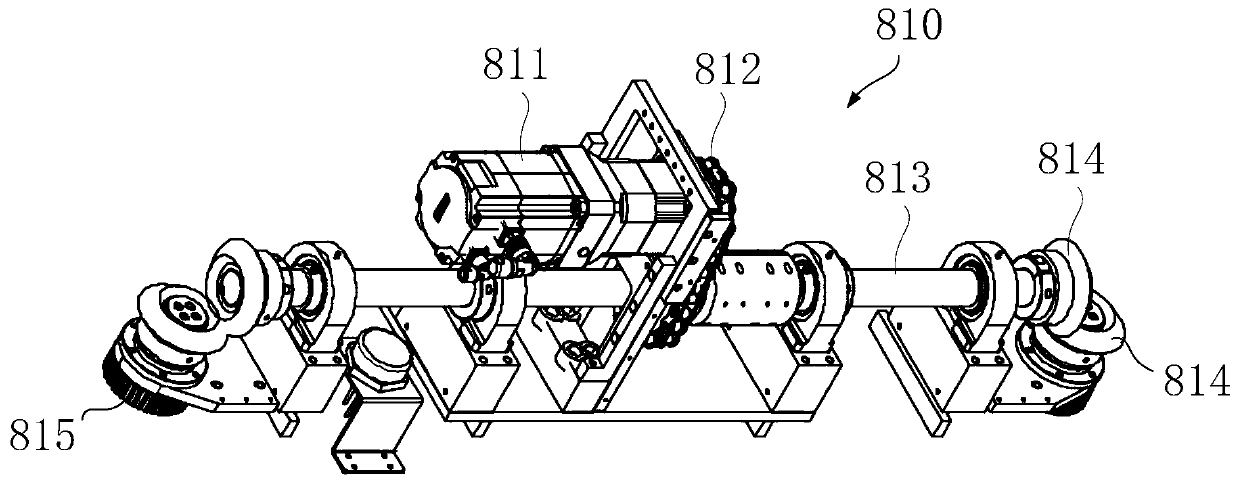

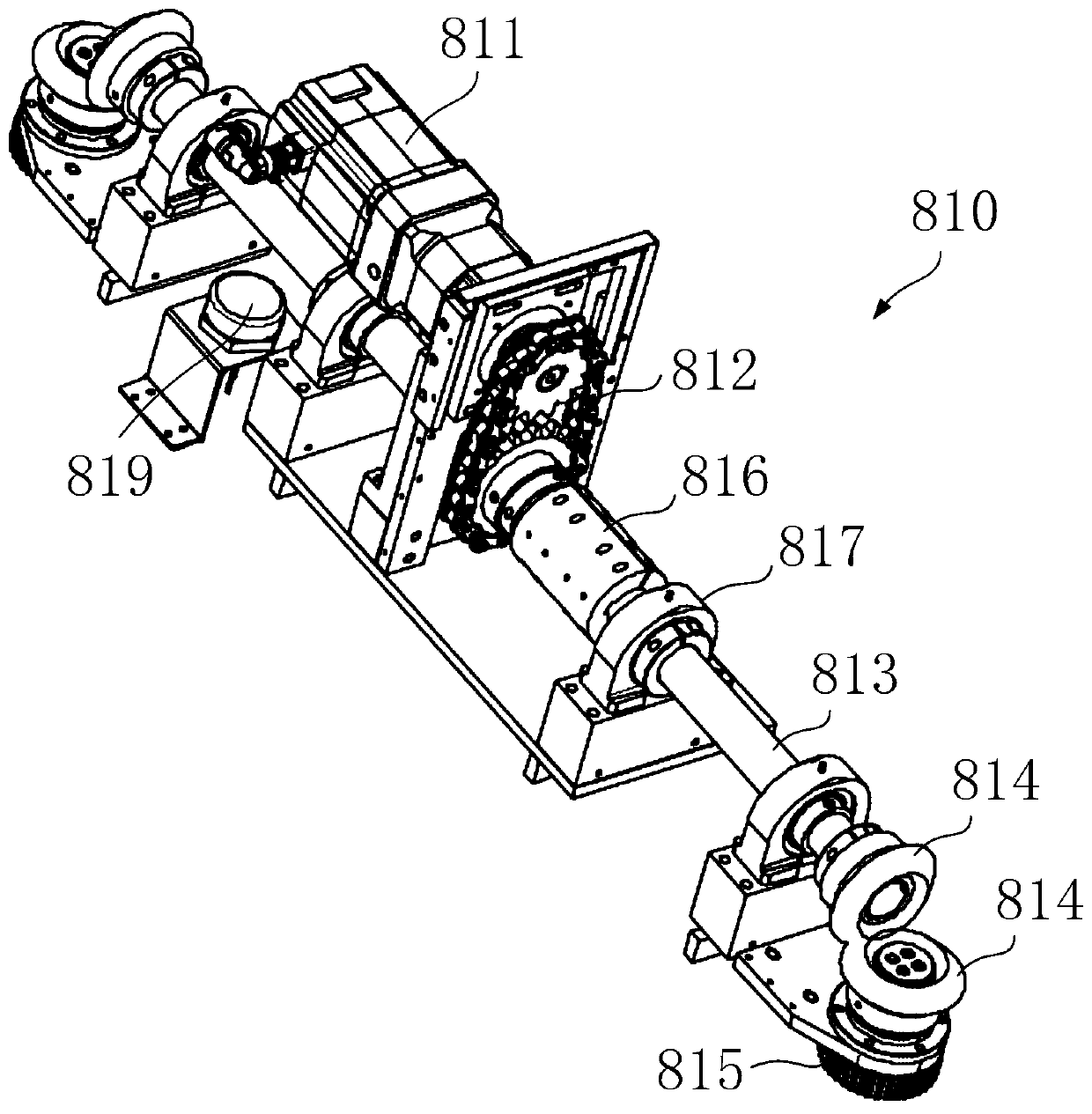

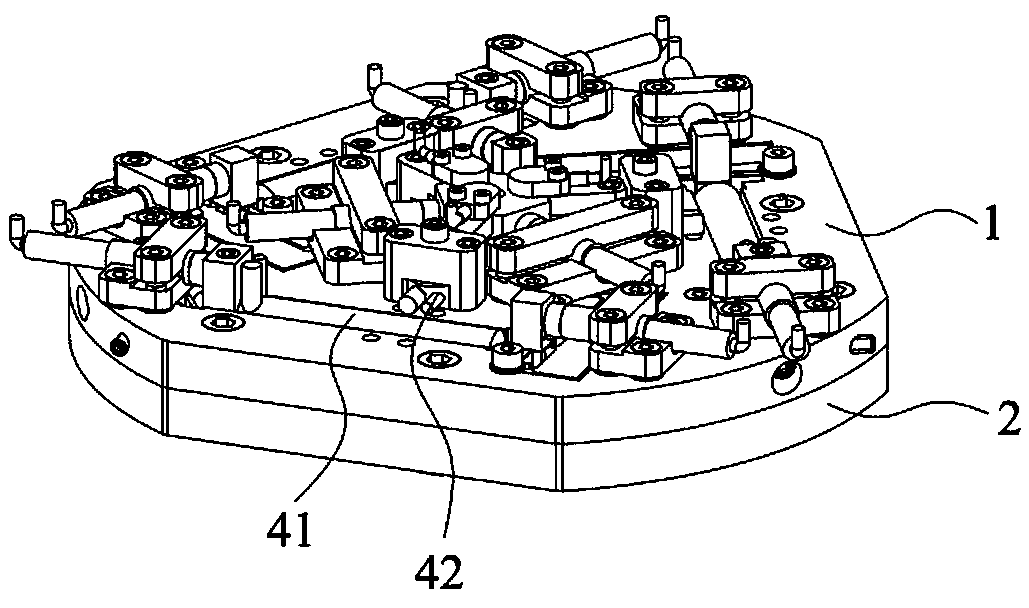

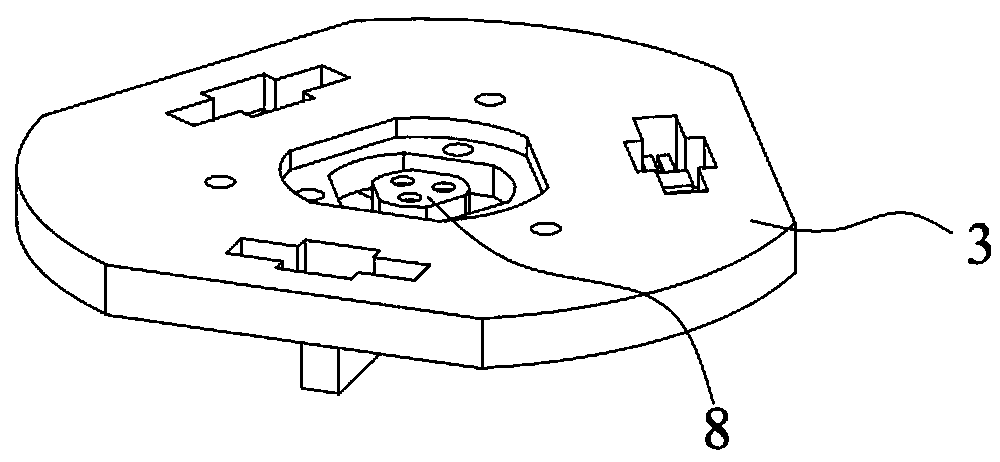

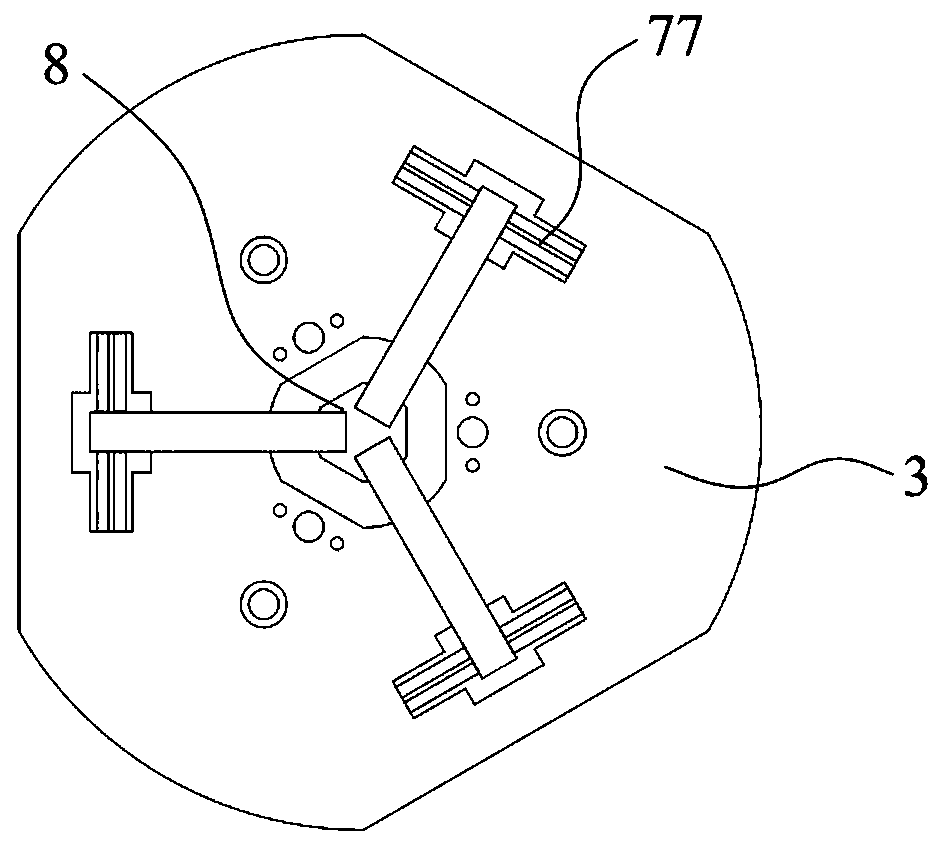

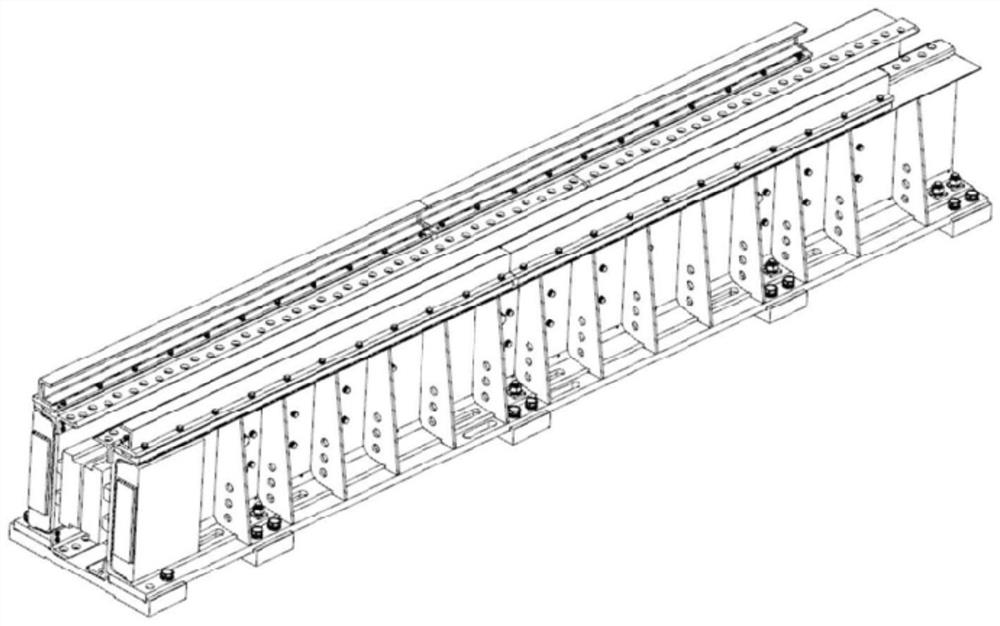

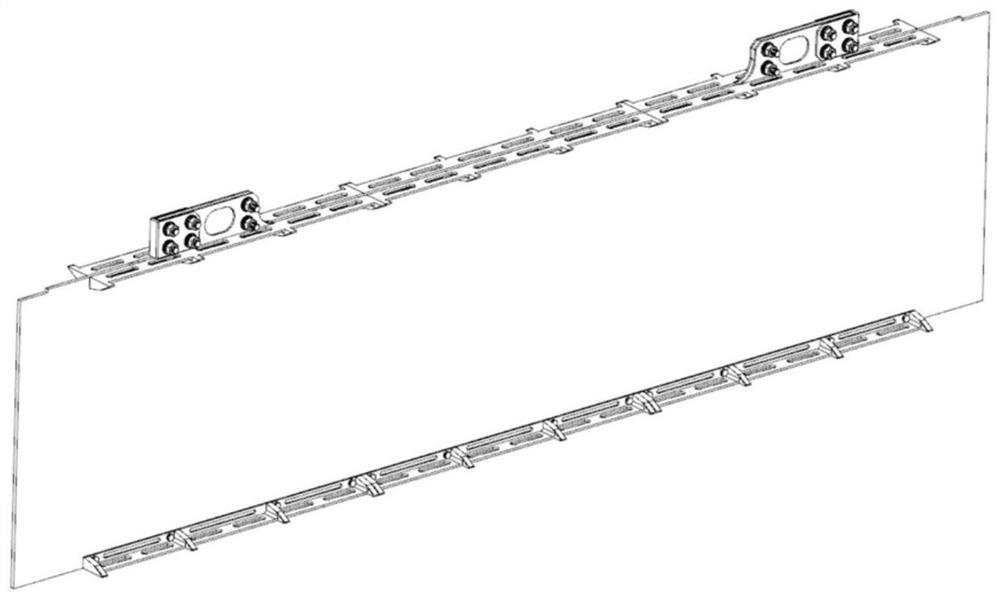

Battery-replacement moving and carrying device capable of achieving floating without lateral force

PendingCN110371088AReduce vertical sizeAvoid bumpingCharging stationsElectric propulsion mountingElectricityNew energy

The invention provides a battery-replacement moving and carrying device capable of achieving floating without lateral force. The battery-replacement moving and carrying device comprises a transverse moving and carrying body, a lifting table body, a fixed base plate, a floating base plate, floating column bodies and clamping mechanism bodies. The transverse moving and carrying body is used for providing driving force for transverse conveying of a battery assembly. The lifting table body is used for elevating the battery assembly on the floating base plate. The floating column bodies are used for floating and supporting the floating base plate so that the floating base plate can float vertically and horizontally relative to the fixed base plate. The clamping mechanism bodies are used for fixing the floating base plate so that the lateral force brought by the floating column bodies in the battery replacement process can be offset. The battery-replacement moving and carrying device is ingenious in structure and reasonable in design, the vertical-direction size of the moving and carrying device is reduced, stable rising and falling are achieved in the battery replacement process, and meanwhile the battery assembly is allowed to float in all directions; and the requirement for positioning of the device is lowered, the lateral force generated in the floating process is eliminated, unnecessary collisions of the battery assembly are avoided, the requirement of new energy vehicles for rapid battery replacement is met, and application and popularization are convenient.

Owner:BOZHON PRECISION IND TECH CO LTD

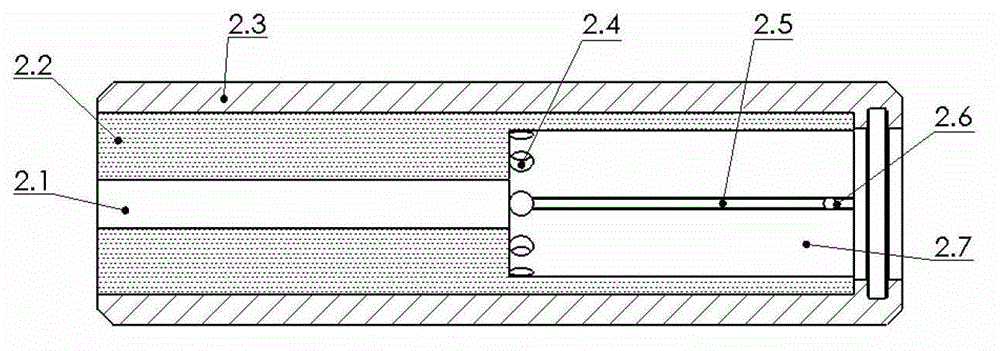

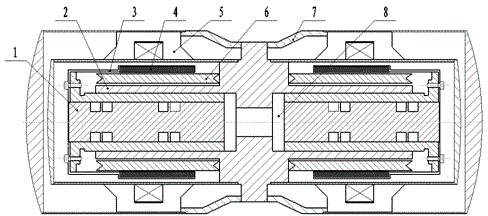

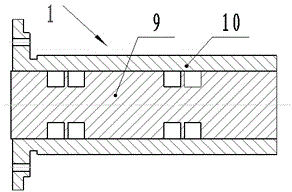

Opposed gas bearing linear compressor

InactiveCN104806471AReduce vibrationReduce noisePiston pumpsPositive-displacement liquid enginesLinear compressorLinear motor

The invention relates to an opposed gas bearing linear compressor. The compressor comprises a cylinder, two pistons distributed in the cylinder in an opposed manner and two linear motors distributed on the outer side of the cylinder in the opposed manner, wherein a compression chamber is arranged in the cylinder; the two pistons are positioned on the two sides of the compression chamber; the pistons and the linear motors on the same sides of the compression chamber correspond to one another one to one; under driving of the respective corresponding linear motors, the two pistons do synchronous opposite reciprocating rectilinear motion along the axial direction of the cylinder. The pistons are unsupported in the axial direction of the cylinder and comprise piston inner sleeves and piston outer sleeves; the outer surfaces of the piston inner sleeves are attached to the inner surfaces of the piston outer sleeves; the piston inner sleeves are provided with inner gas flow passages and gas throttle passages; the piston outer sleeves are provided with outer gas flow passages. Compared with similar linear compressors in the existing technology, the compressor has the advantages of low vibration noise, small piston assembly difficulty, long life and the like, and has great application space in the field of low-temperature refrigeration.

Owner:CHINA ELECTRONICS TECH GROUP CORP NO 16 INST

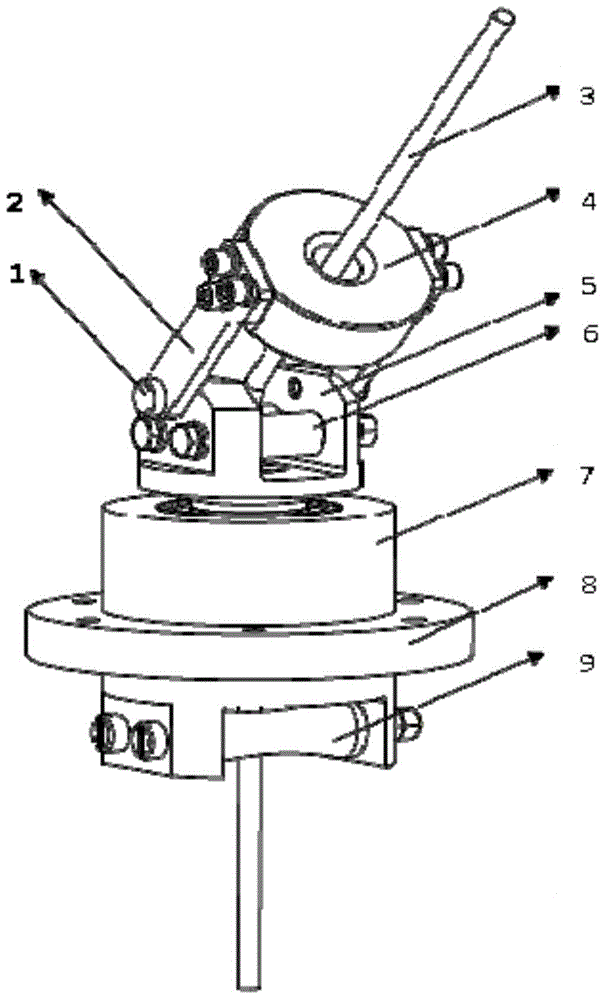

Underwater adaptive mooring cable tension device

InactiveCN104691708AReduce the required powerReduce power consumptionWaterborne vesselsBuoysUnderwaterThrust bearing

The invention discloses an underwater adaptive mooring cable tension device which is mounted on a cable arranging device of an underwater winch of a main floating body of a submerged buoy and comprises a rotary seat, a cable access opening, a base and tension roller trains. The rotary seat is mounted on the base, is connected with the base by a thrust bearing and a radial bearing and can rotate by 360-degree angles on the horizontal plane. The cable access opening is connected onto the rotary seat by hinge support arms, and the hinge support arms can rotate around hinge shafts. The tension roller trains are arranged in the rotary seat and the base, and a mooring cable which is fed into the underwater adaptive mooring cable tension device from the cable access opening and penetrates the rotary seat and the base can be clamped by the tension roller trains. The underwater adaptive mooring cable tension device has the advantages that the rotary seat can rotate, the hinge support arms can rotate around the shafts, accordingly, the direction of tension for pulling a floater in the cable access opening can keep in the longitudinal direction of the mooring cable, loosening, tightening and shaking of the mooring cable due to fluctuation of waves and transverse acting force which is applied to the mooring cable under the effect of sea current can be effectively eliminated, and the environmental adaptability and the severe sea condition resistance of the underwater winch can be improved.

Owner:STATE OCEAN TECH CENT

Drum-type friction screw press

InactiveCN101612803ARealize moving up and downRealize two-way rotationPress ramFreewheelHydraulic cylinder

The invention discloses a drum-type friction screw press, which belongs to a forge press machine. The drum-type friction screw press comprises a machine base and a horizontally rotating flywheel, wherein the flywheel is connected with a screw; the screw drives a sliding block to move up and down; the inside of the flywheel is provided with an accommodating cavity comprising the outer wheel rim and the inner wheel rim of the flywheel; friction wheels are radially and symmetrically arranged in the accommodating cavity; the friction wheels are driven by a motor through a belt to automatically rotate in the same direction; and the frication wheels are connected with a piston rod of an oil hydraulic cylinder and press the outer wheel rim and the inner wheel rim of the flywheel under the push of the piston rod respectively. For both the pressing and lifting of the sliding block, the friction wheels on the two sides oppositely press the flywheel with equal forces to rotate the flywheel. Thus, the drum-type friction screw press can eliminate the lateral force applied on the screw and prolong the service life of equipment.

Owner:SHANGHAI YUNLIANG FORGING PRESS

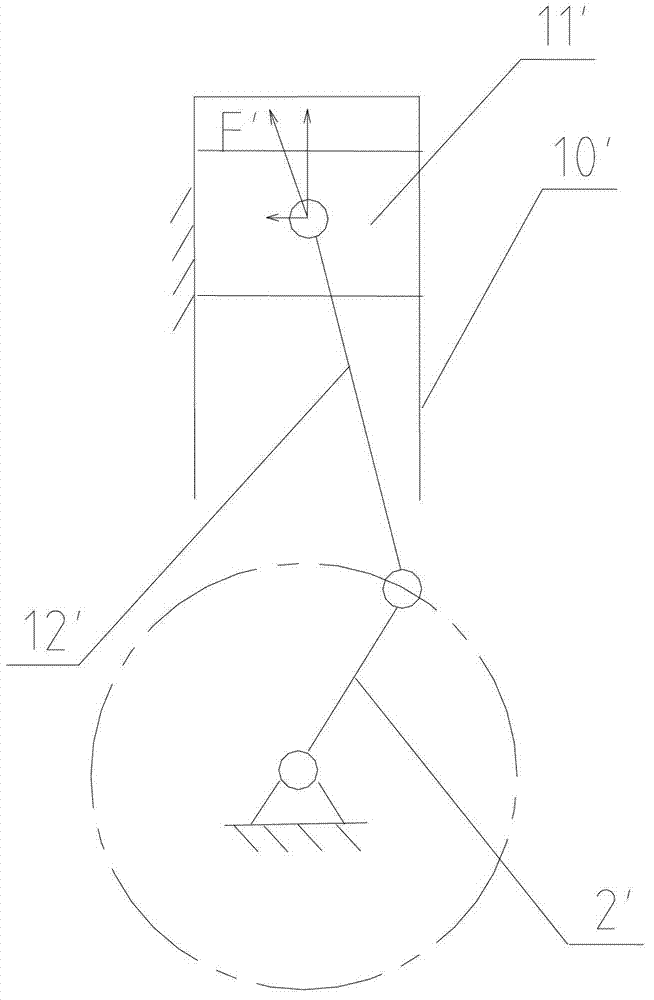

Dumper

InactiveCN102689608AImprove stabilityGreat driving forceVehicle with tipping movementCrankshaftPiston rod

The invention provides a dumper. The dumper comprises a vehicle body and wheels mounted on the vehicle body. The dumper further comprises at least one driving unit, wherein the driving unit comprises at least one oil cylinder and a crank; the crank comprises a spindle neck and a connecting rod shaft neck; the crank is rotatably mounted on the vehicle body of the dumper through the spindle neck; the oil cylinder is mounted on the vehicle body in a swinging manner; the piston rod of the oil cylinder is connected with the connecting rod shaft neck; the oil cylinder can drive the crank to rotate; the crank is fixedly connected with the wheels; and the oil cylinder can drive the wheels to rotate through the crank. According to the technical scheme of the invention, the crank is driven by a hydraulic force, and rotary power is output. The dumper has the obvious advantages of large output torque, stable operation, no un-balance loading, full-stroke acting, simple structure and the like, is convenient to control, space-saving and easy to implement.

Owner:SANY HEAVY IND CO LTD (CN)

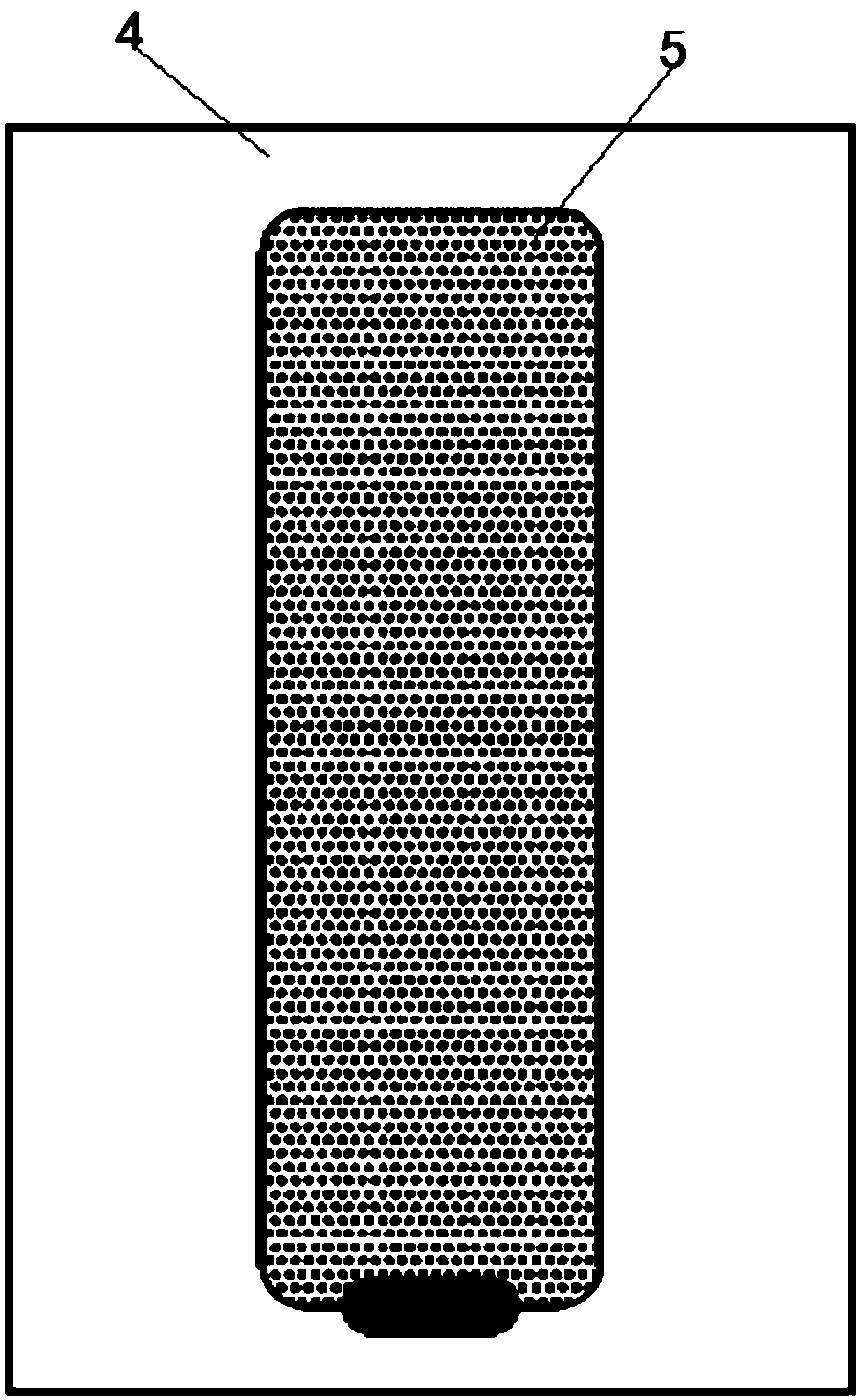

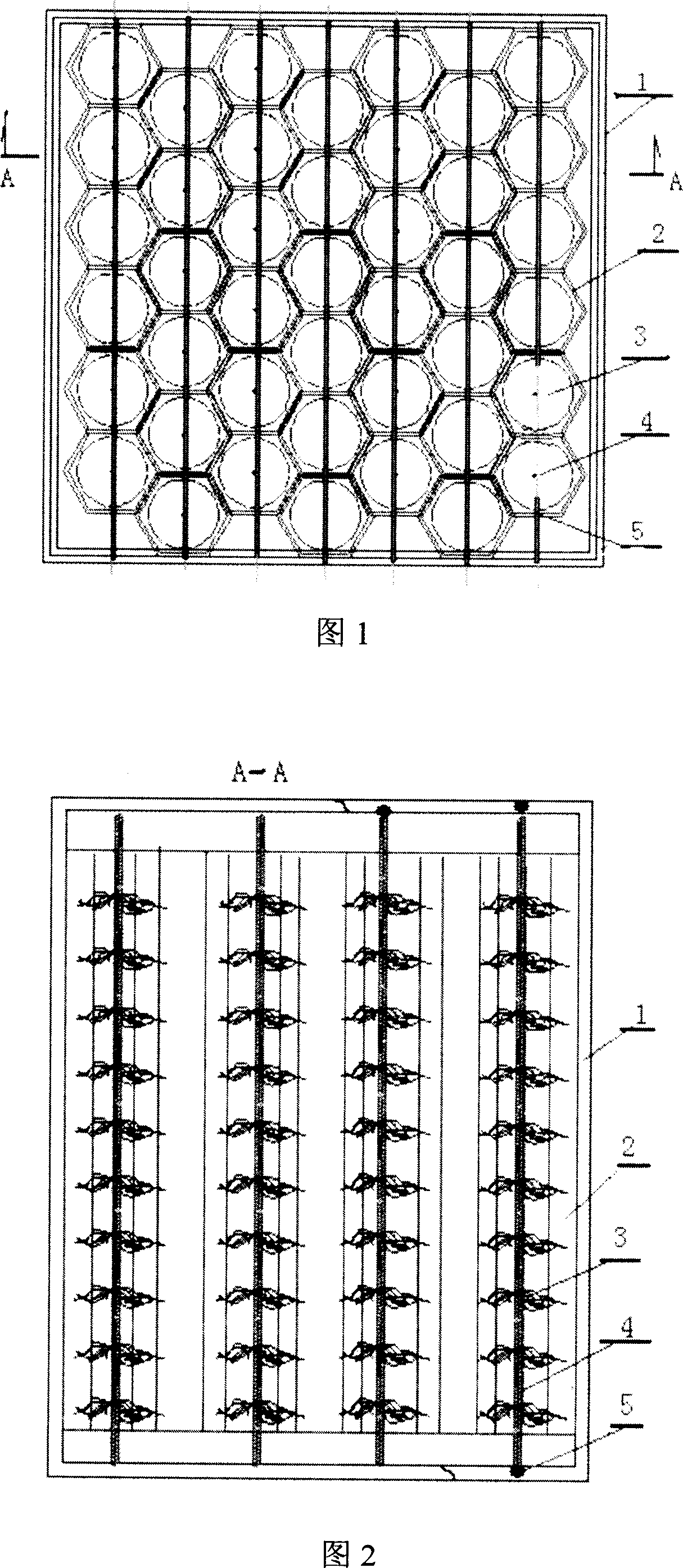

Fiber filtering component with honeycomb wall cross section structure

InactiveCN101007677AEliminate lateral forceNo entanglementSustainable biological treatmentBiological water/sewage treatmentFiberHoneycomb

The invention discloses a fiber filter component with honeycomb cell wall section, which comprises the following parts: exterior frame, honeycomb cell wall and fiber filter, wherein the honeycomb cell wall and hollow fiber filter form continuous cell, which cascades through central thread on the upper and lower baffles of external frame; the honeycomb cell wall displays opened hexaprismatic straight-pipe.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

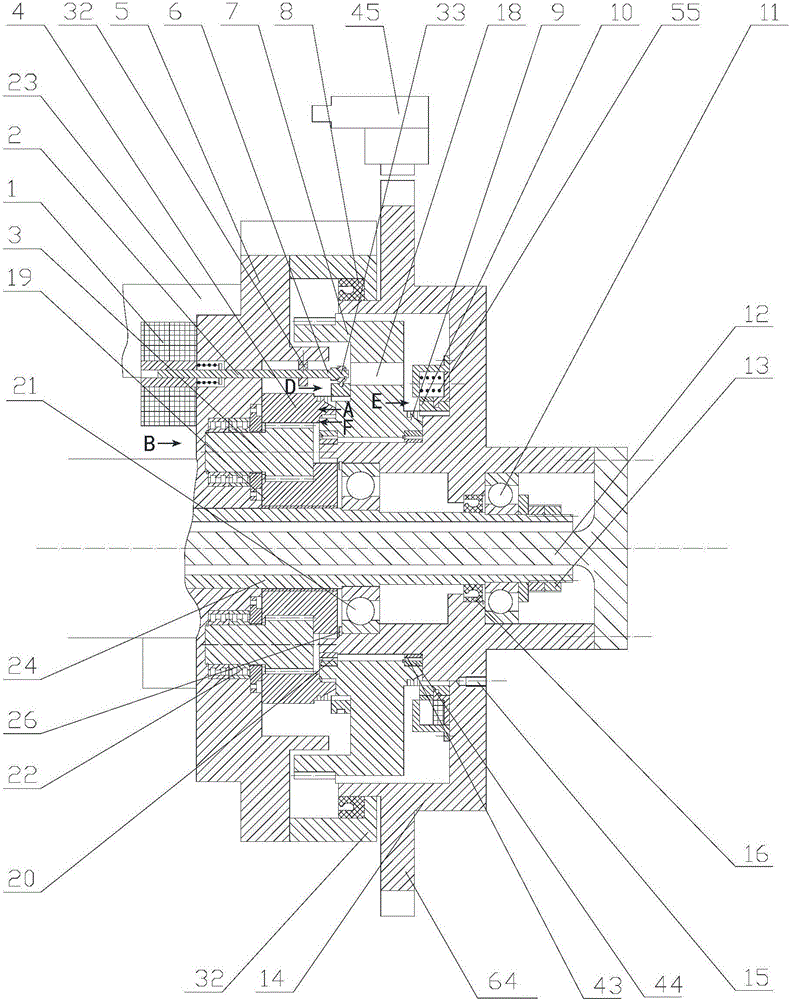

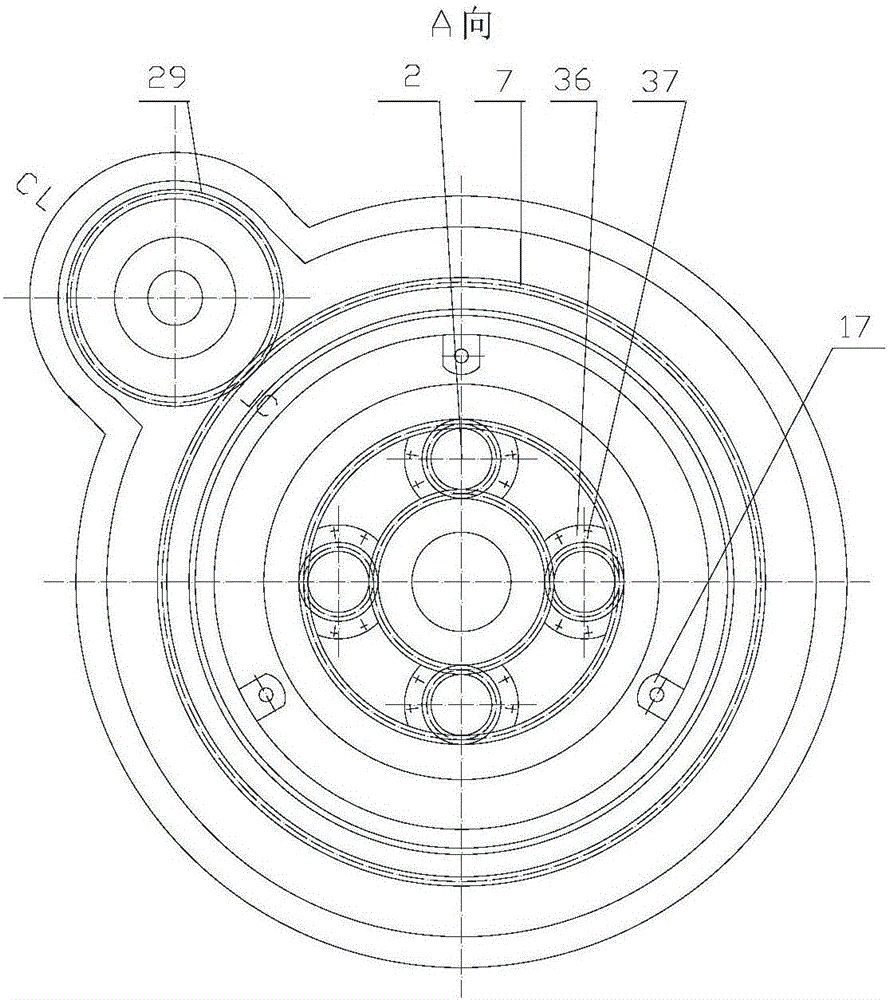

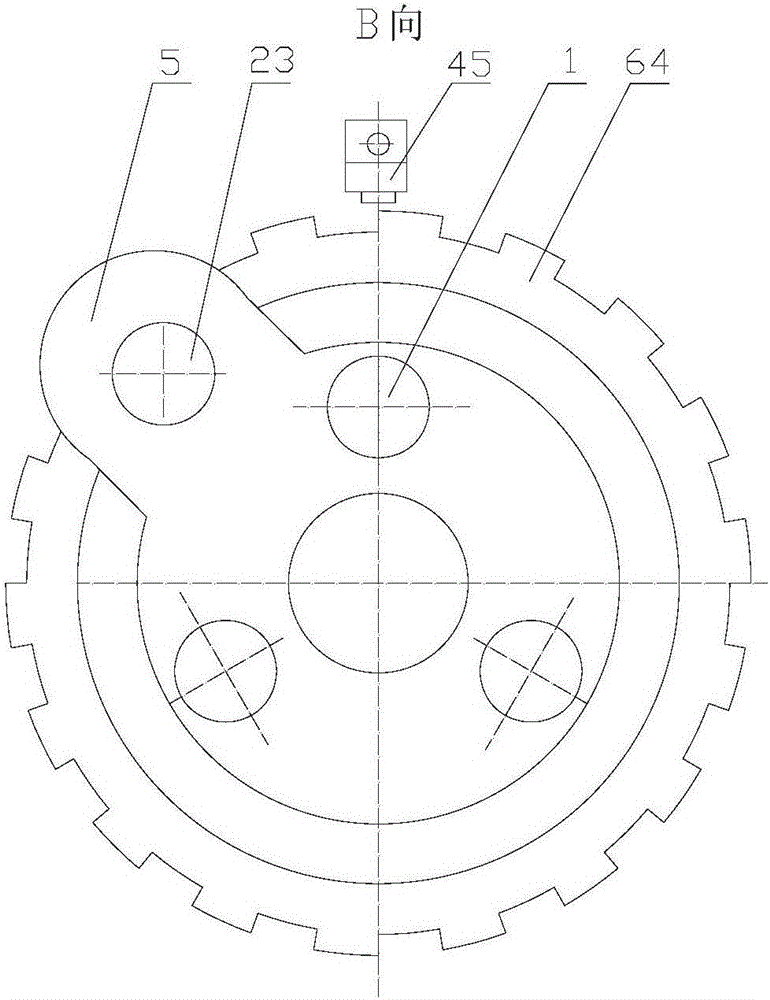

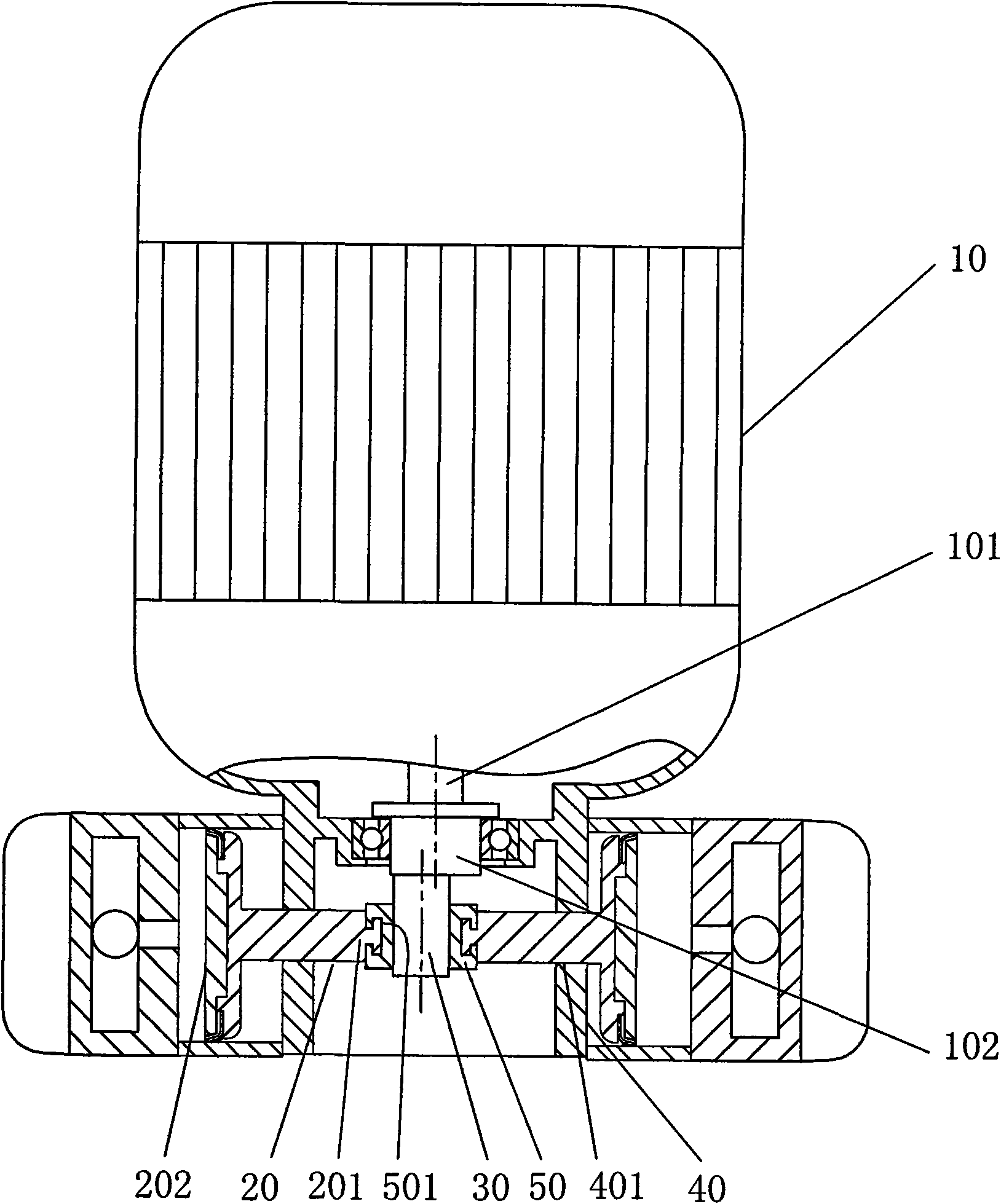

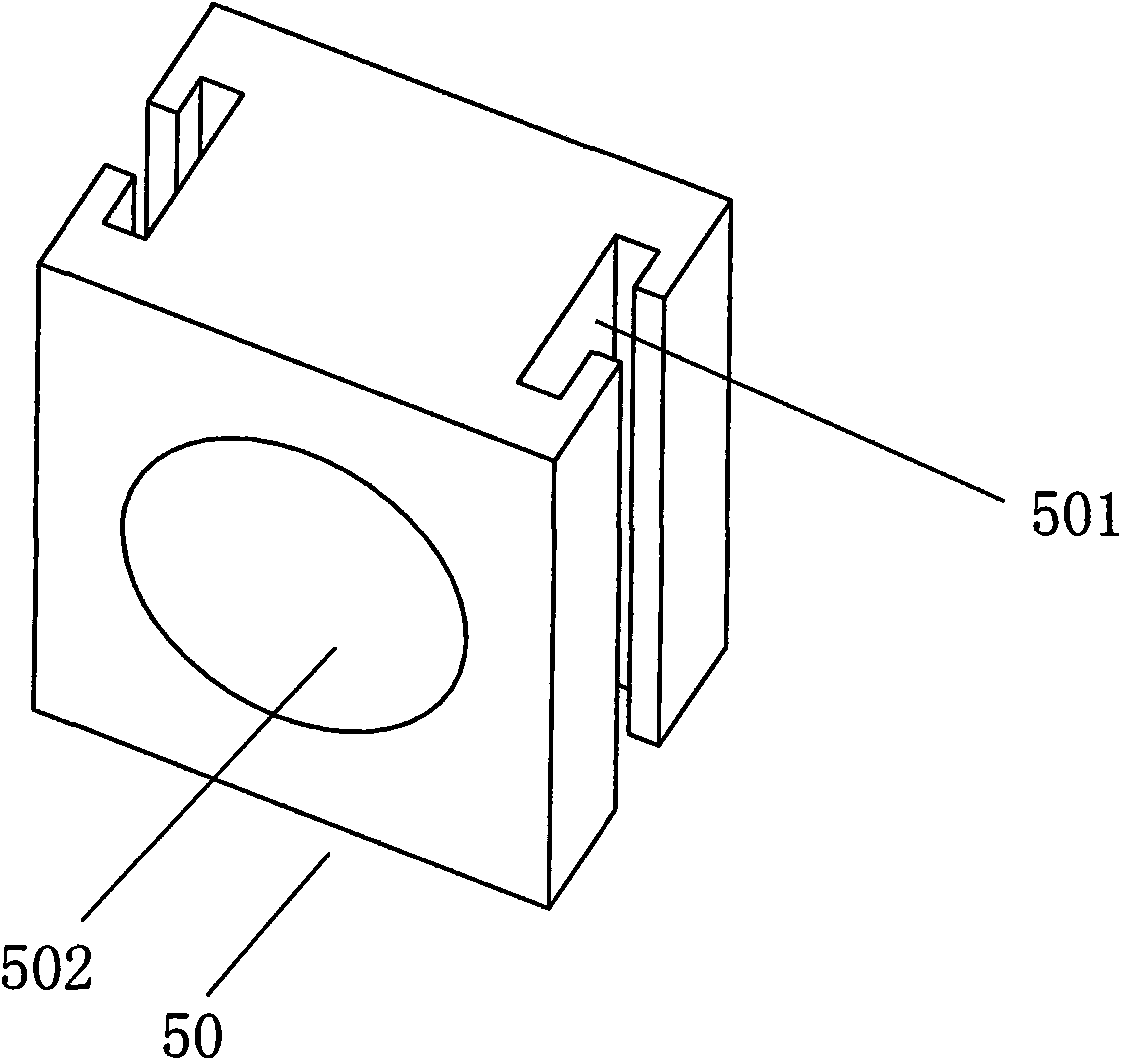

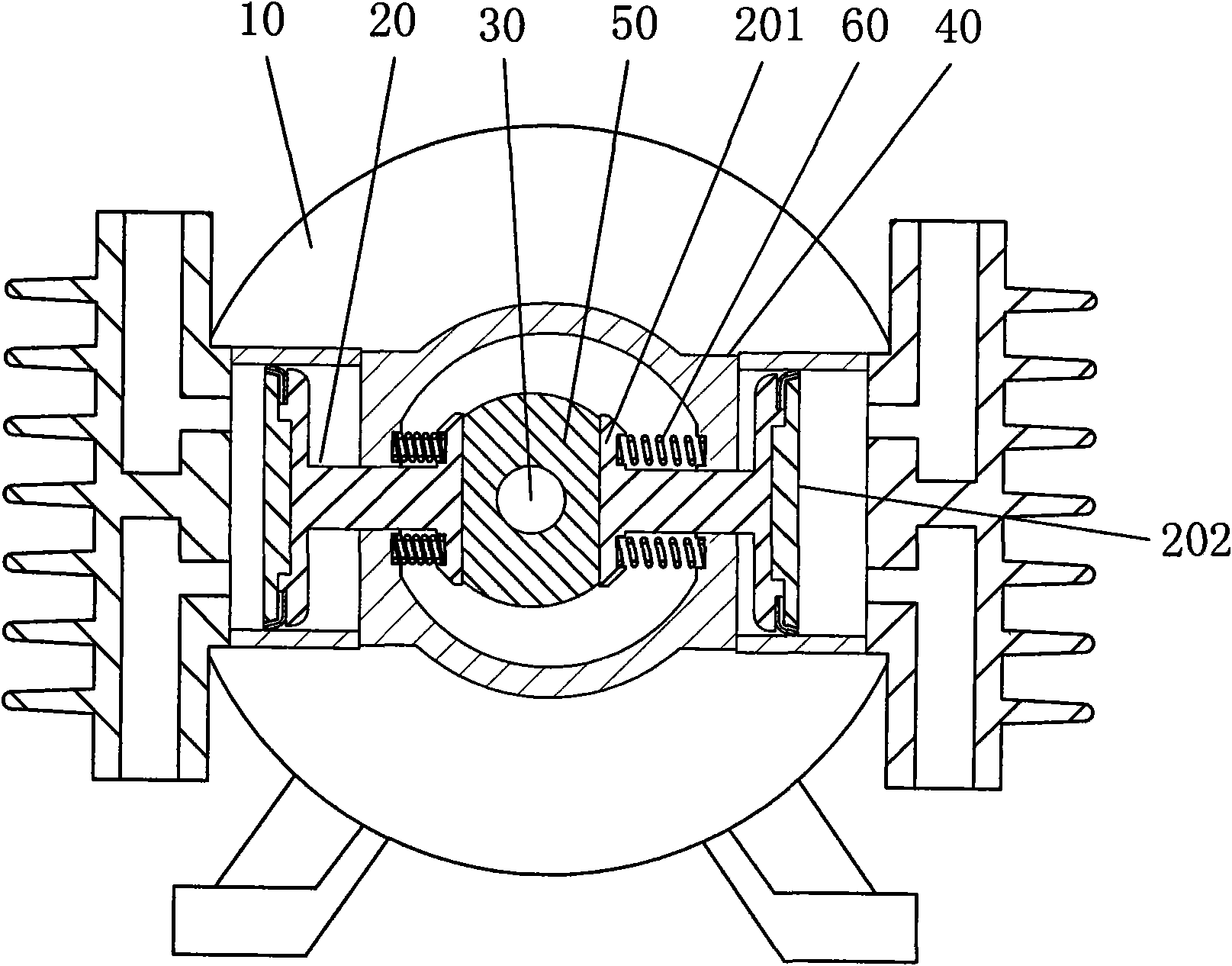

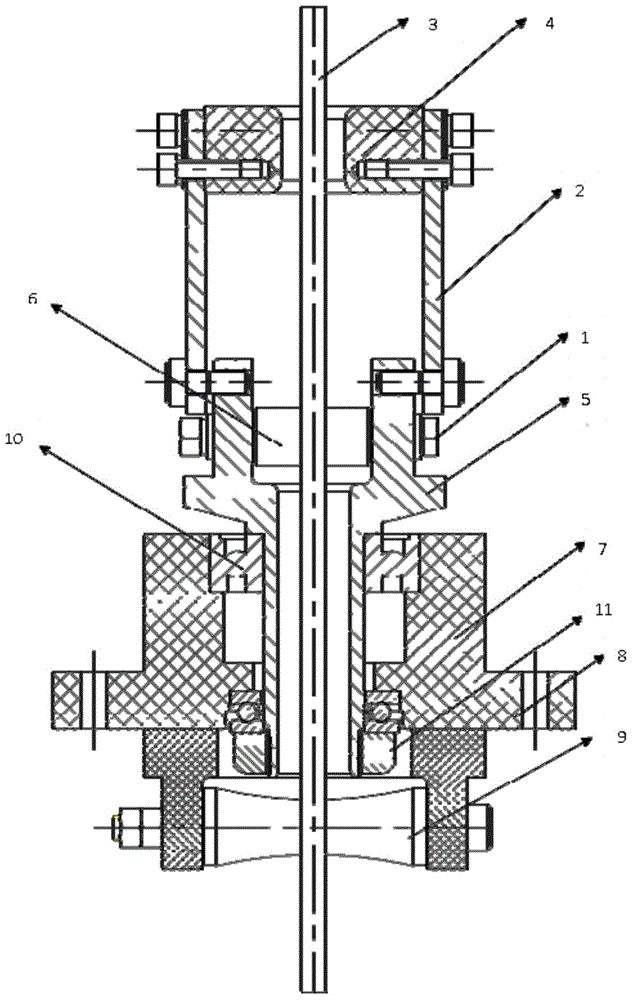

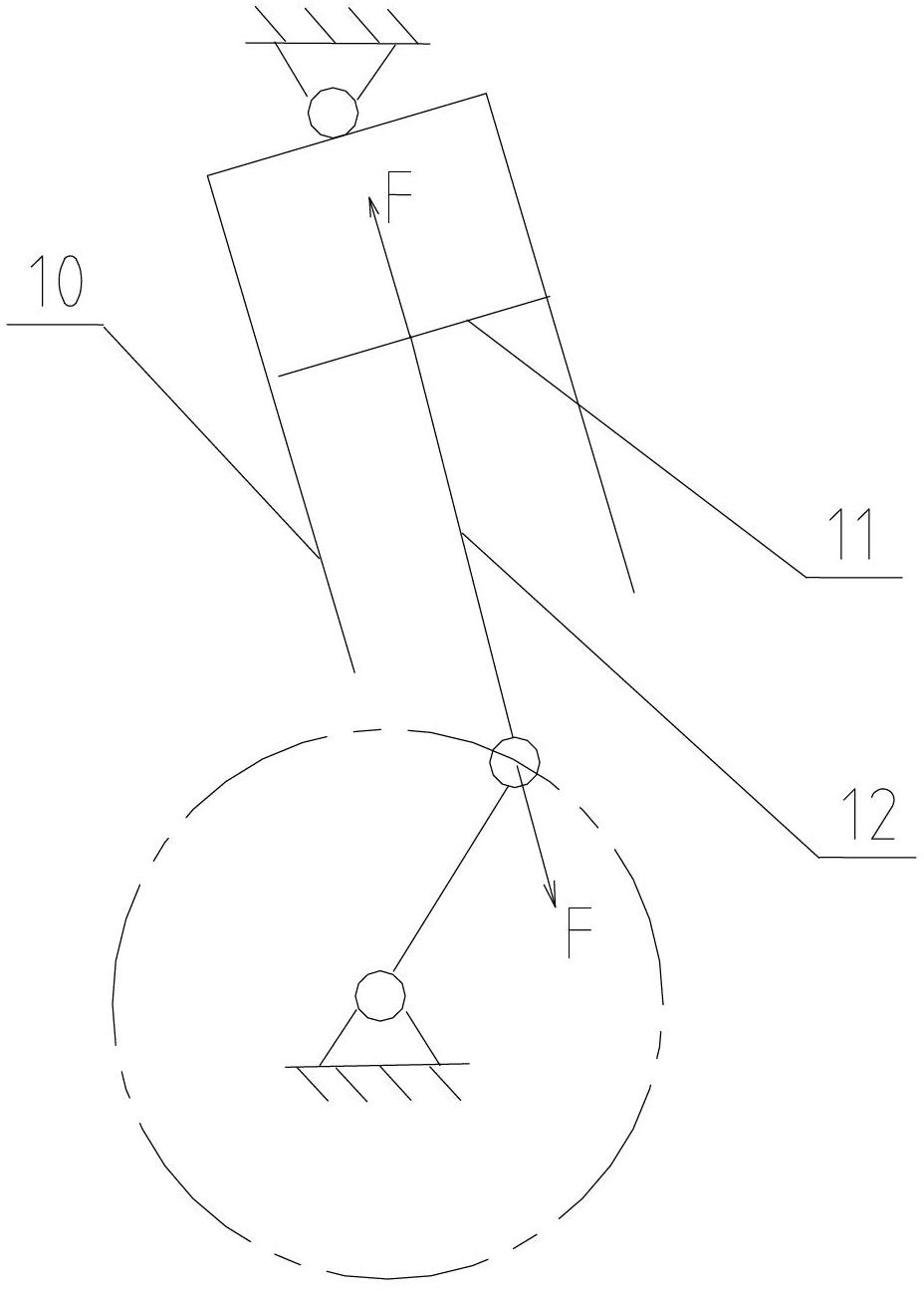

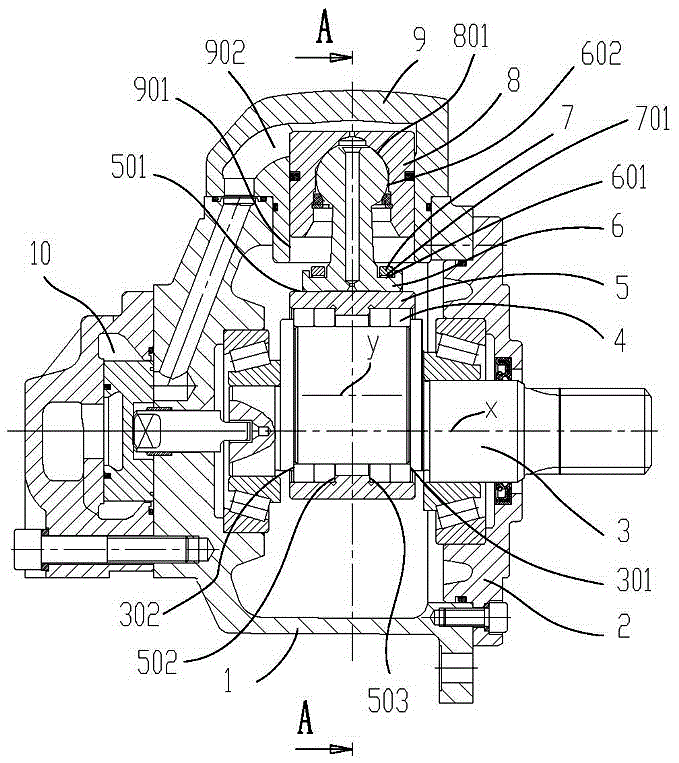

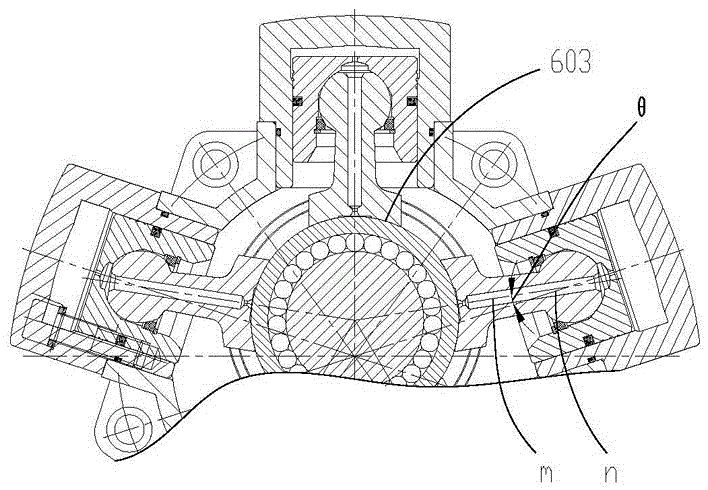

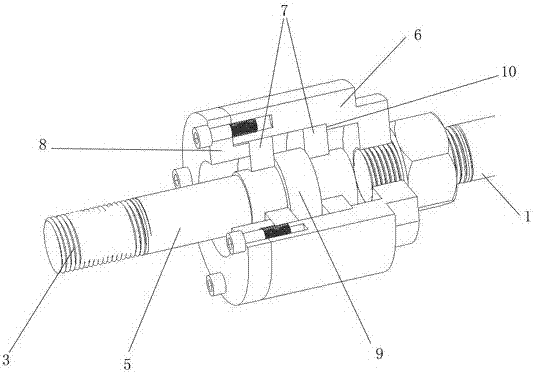

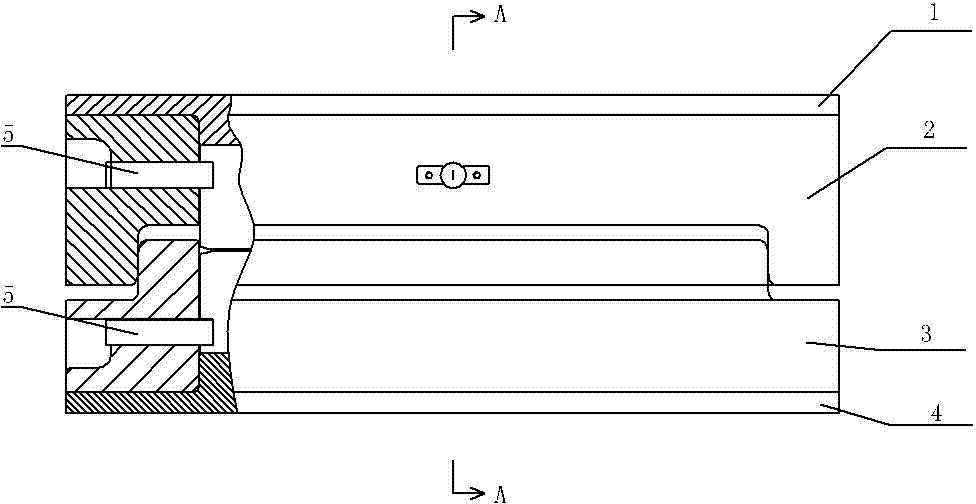

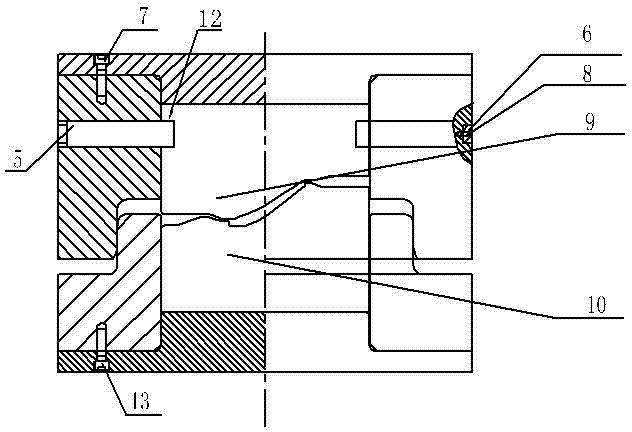

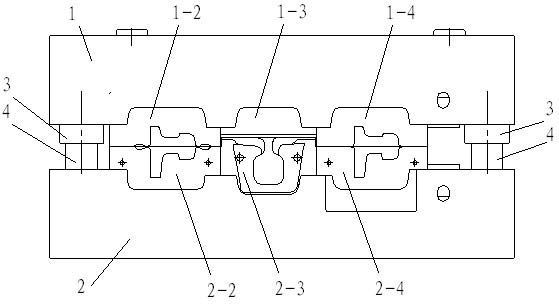

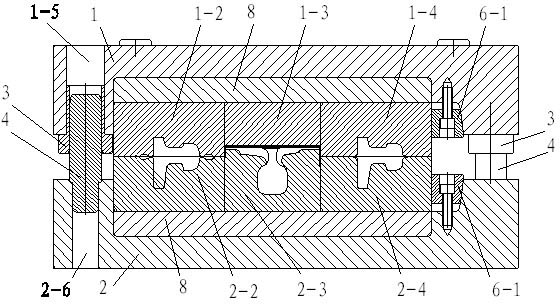

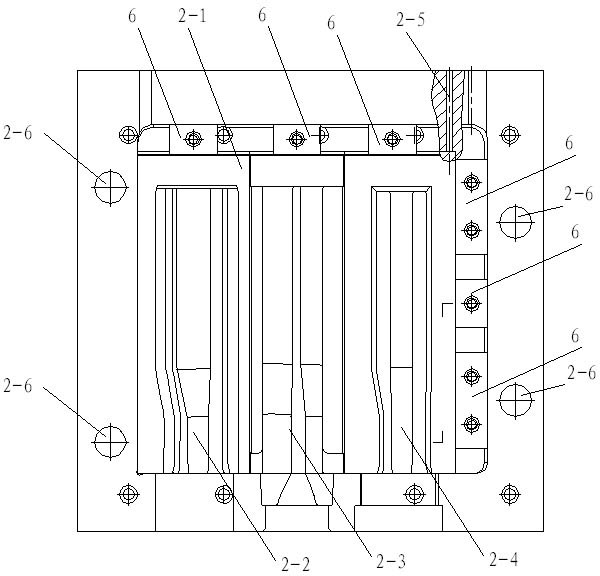

Intermediate-speed large-torque radial plunger hydraulic motor

ActiveCN105756850AEliminate lateral forceEliminates the phenomenon of oval wearPlungersTrunk pistonsHydraulic motorCylinder head

The invention relates to an intermediate-speed large-torque radial plunger hydraulic motor which comprises a casing (1), a crankshaft (2), a roller (3), a bearing bush (4), a cylinder head (5), a telescopic sleeve (6), a retainer ring (7), a hanger rod (8) and a drive shaft (10).The telescopic sleeve (6) is arranged along the radial direction of the bearing bush (4), and the upper end and the lower end of the telescopic sleeve (6) are respectively abutted against an external spherical surface (501) of the cylinder head (5) and an external spherical surface (402) of the bearing bush (4).The lower end of the telescopic sleeve (6) is closely attached to the external spherical surface (402) of the bearing bush (4) by the retainer ring (7).The upper end of the telescopic sleeve (6) is closely attached to the external spherical surface (501) of the cylinder head (5) by the hanger rod (8).Two ends of the drive shaft (10) are respectively connected with the crankshaft (2) and an oil distributing mechanism (9).The roller (3) is inserted in an inner bore (401) of the bearing bush; and the crankshaft (2) comprises an eccentric section (201).Compared with the prior art, the radial plunger hydraulic motor has the advantages of highly increased revolution speed and compact structure.

Owner:INTRA ITAL HYDRAULICS FOSHAN SHUNDE

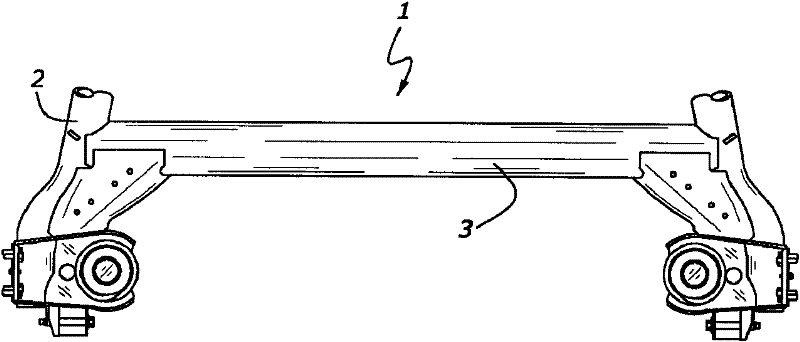

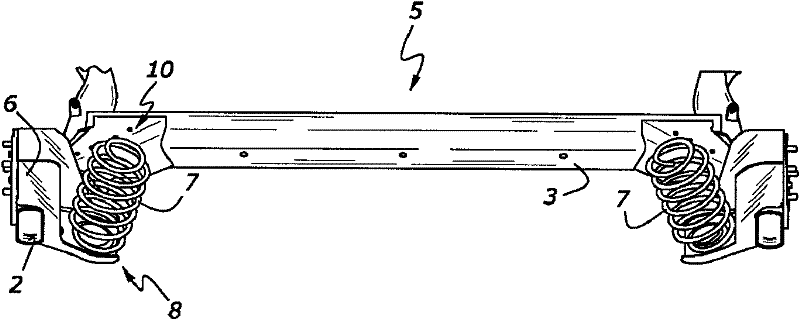

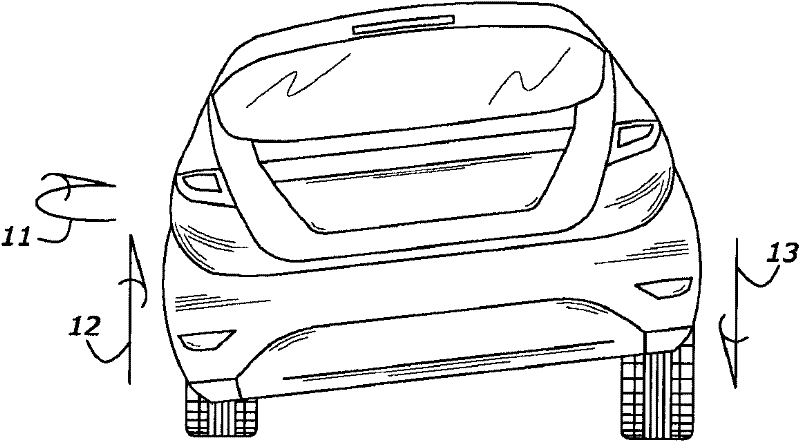

Rear wheel suspension with coil springs with an inclined reaction force axis

InactiveCN102211509ASmall sizeReduce weightInterconnection systemsResilient suspensionsCoil springHelix

The invention relates to a rear wheel suspension 1 with coil springs with an inclined reaction force axis, which has a spring 7, preferably embodied as a coil spring 7 that has a geometric spring center line and a line 9 of action of force, the coil spring 7 being supported in an upper and a lower spring mount. In order to reduce the forces imposed on structural elements of the rear wheel suspensio 1n, the proposal is that the spring 7 be embodied and arranged in such a way that the line 9 of action of force thereof has an amount of tilt during an inward deflection which is different from an amount of tilt during an outward deflection.

Owner:FORD GLOBAL TECH LLC

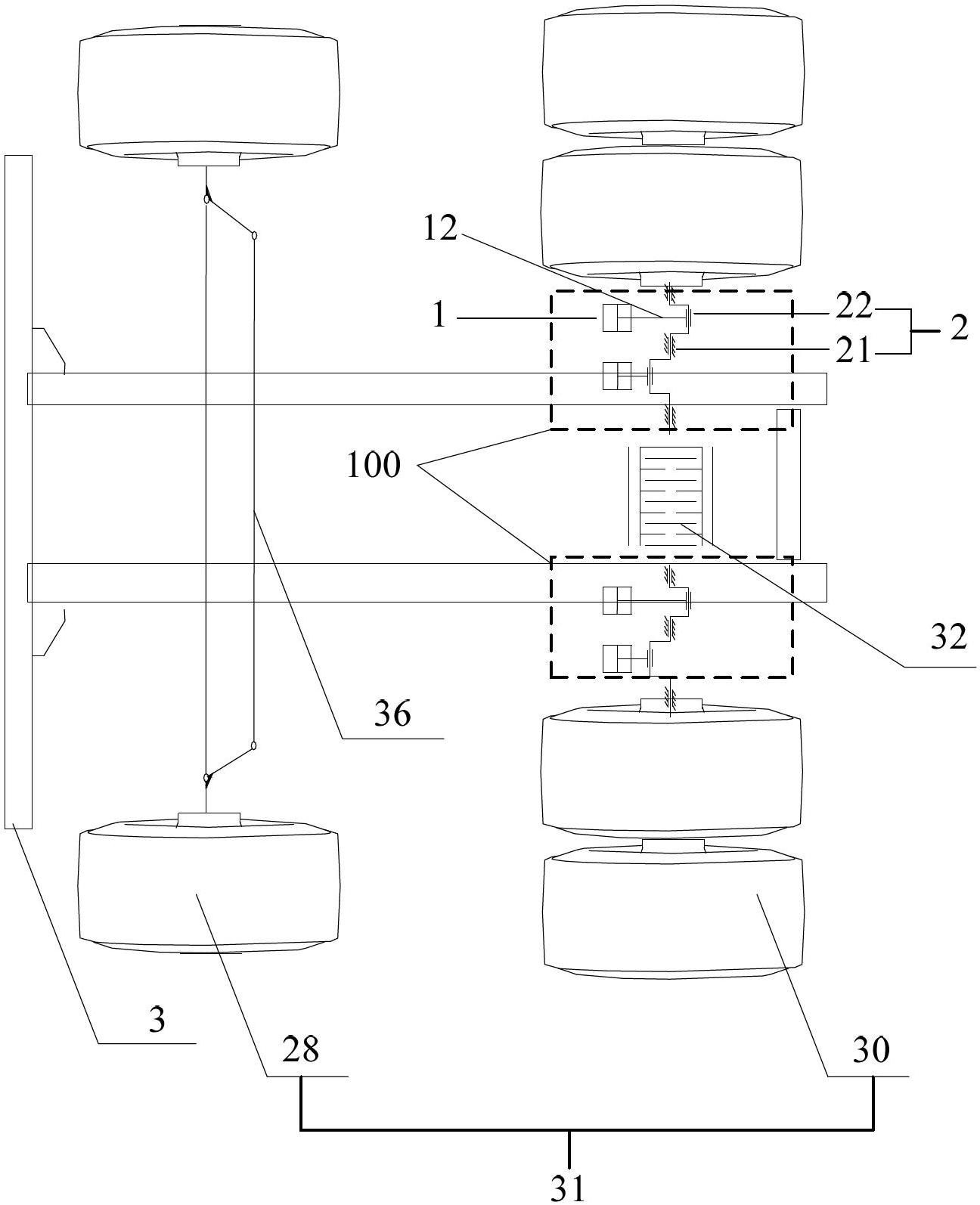

Four-wheel friction screw press

InactiveCN101612641AEliminate lateral forceLarge forging capacityForging press drivesFreewheelHydraulic cylinder

The invention discloses a four-wheel friction screw press, which comprises a horizontally rotating flywheel, wherein the flywheel is connected with a screw; the two sides of the flywheel are both symmetrically provided with an upper friction wheel and a lower friction wheel, the flywheel is driven by a motor to rotate, and the upper friction wheels and the lower friction wheels rotate in the same direction; the rotating shafts of the upper friction wheels and the lower friction wheels are movably connected with the two ends of a lever by pins; and the lever is driven by an oil hydraulic cylinder to swing around a fulcrum serving as a center of a circle to control the upper friction wheels and the lower friction wheels to alternately press or separate from the wheel rim of the flywheel. During operation, the piston rod of the oil hydraulic cylinder moves toward the central flywheel, the two lower friction wheels synchronously press the lower rim of the flywheel, the flywheel rotates rightward and a sliding block is pressed down; and the piston rod of the oil hydraulic cylinder moves outward, the two upper friction wheels synchronously press the upper rim of the flywheel, the two lower friction wheels separate from the flywheel, the flywheel rotates leftward and the sliding block is lifted. The friction wheels on the two sides press the flywheel with equal forces, so the screw press can eliminate the lateral force applied on the screw and obtain high forcing performance and high production efficiency under the condition of load increase.

Owner:SHANGHAI YUNLIANG FORGING PRESS

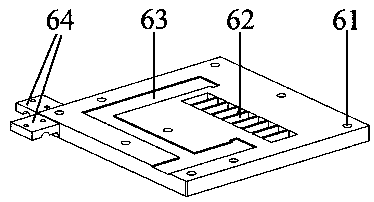

Multi-degree-of-freedom nanometer positioning platform based on flexible parallel mechanism

ActiveCN109502542AHigh precisionHigh output stiffnessMicrostructural devicesPosition/direction controlMicro nanoHigh bandwidth

The invention relates to the technical field of micro-nano machining and manufacturing devices, in particular to a multi-degree-of-freedom nanometer positioning platform based on a flexible parallel mechanism. Branch movement chains include a first branch movement chain and a second branch movement chain; one end of the first branch movement chain is connected with a first fixed base, and the other end of the first branch movement chain is connected with an end executor; and one end of the second branch movement chain is connected with the first fixed base, a supporting point is provided by asecond fixed base, and the other end of the second branch movement chain is connected with the end executor. The end executor can realize single-degree-of-freedom output through the multi-axis secondbranch movement chain in a vertical direction; through redundant driving with the nanoscale precision, high output rigidity, high acting force, large load capacity, high bandwidth and high precision in the vertical direction can be realized; and the platform can be used as a main shaft in the fields of micro-nano machining and manufacturing, and the like.

Owner:GUANGDONG UNIV OF TECH

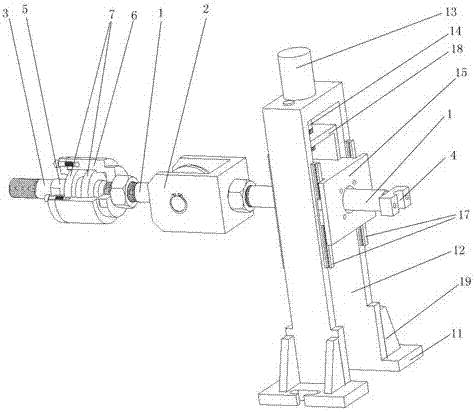

Three-axis cutter servo device based on compliant parallel mechanism

ActiveCN109079552ARealize displacement outputIncrease stiffnessFeeding apparatusHigh bandwidthHigh stiffness

The invention relates to the technical field of nano-positioning, measuring and machining devices, in more particularly to a three-axis cutter servo device based on a compliant parallel mechanism. Thethree-axis cutter servo device comprises outer side fixing bases, an inner side fixing base, uniaxial nano-positioning platforms and a three-axis end actuator, wherein the uniaxial nano-positioning platforms and the three-axis end actuator transfer motion through compliant hinges and flexible rod pieces. The three-axis end actuator is connected with a cutter and provided with a capacitive sensor,and the capacitive sensor is connected with a controller. The output end of the controller is connected with a piezoelectric ceramic driver, the piezoelectric ceramic driver is connected to the inputends of the uniaxial nano-positioning platforms, and the three-axis end actuator is connected to the output ends of the three uniaxial nano-positioning platforms. According to the three-axis cutter servo device based on the compliant parallel mechanism, nanoscale linear displacement of the three-axis end actuator can be output, meanwhile, end output displacement is directly measured through the sensor, feedback control is conducted, and the three-axis cutter servo device has high stiffness, high precision, the high bandwidth, the large stroke, the high speed, high acceleration, the large bearing capacity and excellent decoupling performance.

Owner:GUANGDONG UNIV OF TECH

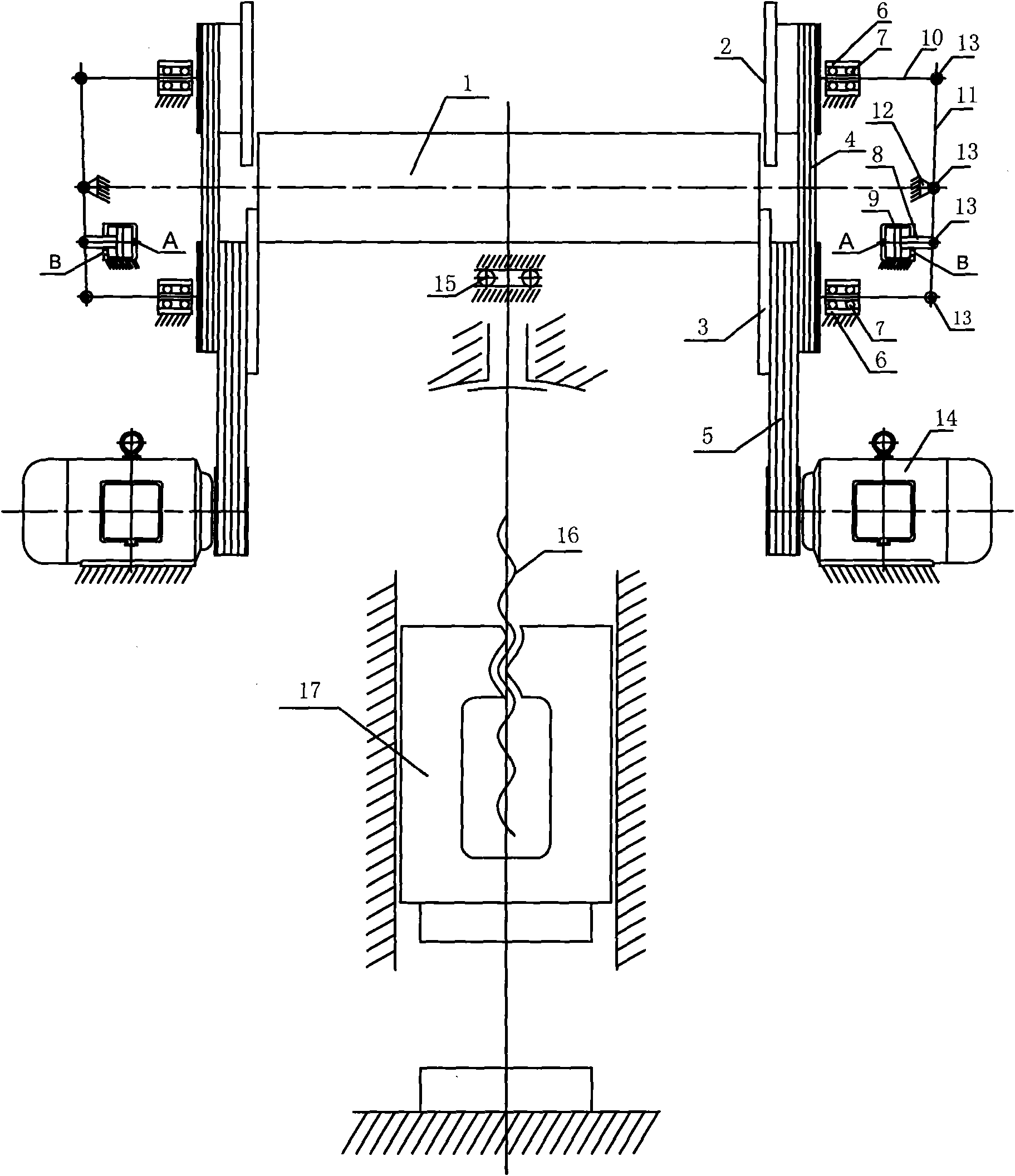

Auxiliary frame fatigue test bending moment and torque elimination device

InactiveCN107478442ASmall height deviationEliminate bending momentVehicle testingMachine part testingDrive shaftUniversal joint

The invention aims at providing an auxiliary frame fatigue test bending moment and torque elimination device comprising a spindle, a height adjusting device, a universal joint, a transmission shaft and a torque elimination device. The spindle is installed on the height adjusting device and can perform elevating motion along a vertical direction under the effect of the height adjusting device. The two ends of the spindle are arranged at the two sides of the height adjusting device. The front end of the spindle is provided with the universal joint, and the rear end of the spindle is provided with a workpiece connecting part. The torque elimination device is connected with the universal joint through the spindle. The other end of the torque elimination device is connected with the transmission shaft. The defects in the prior art can be overcome by the device, and the device has the characteristics of eliminating the bending moment and the torque and enhancing the service life and the test accuracy.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

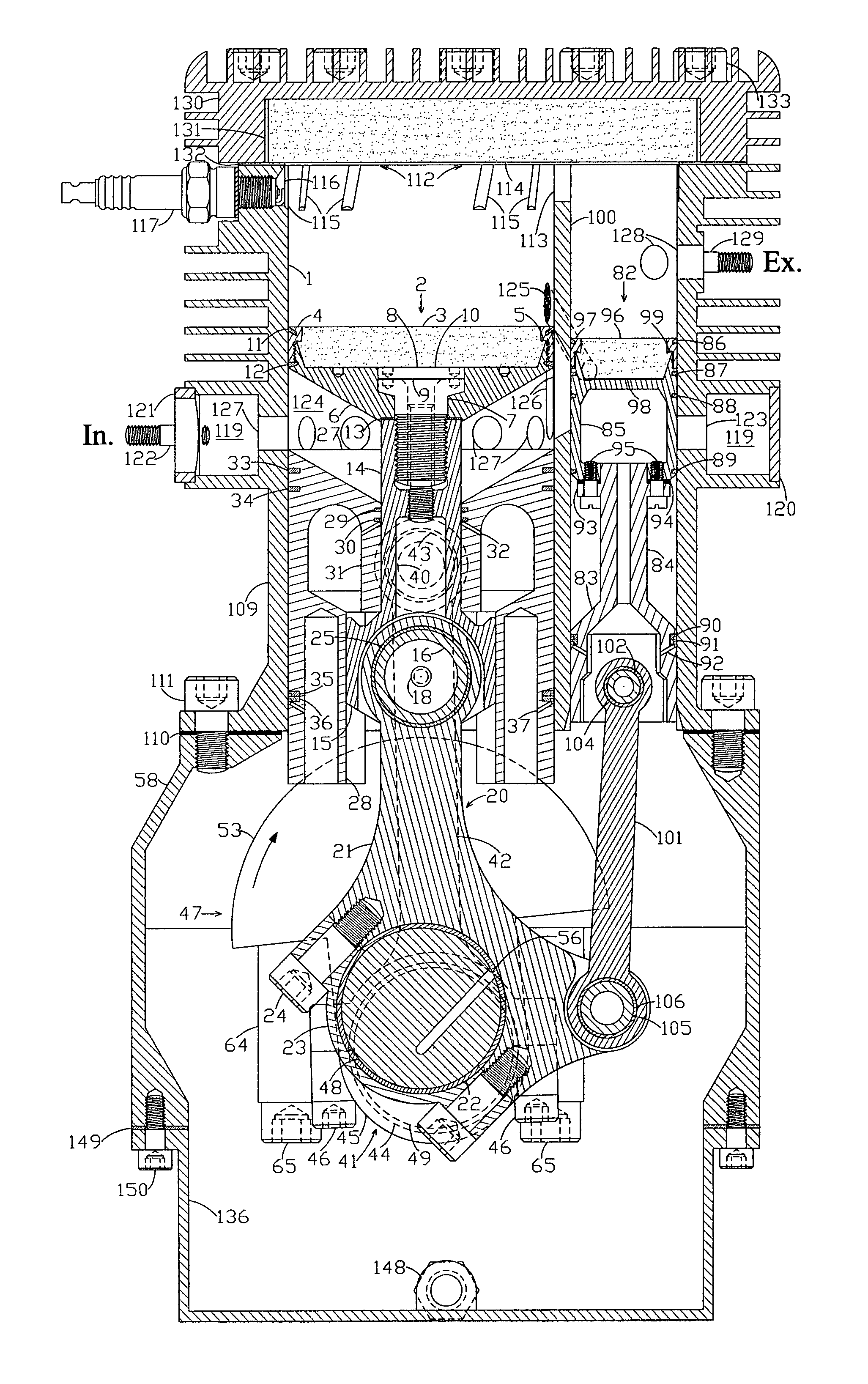

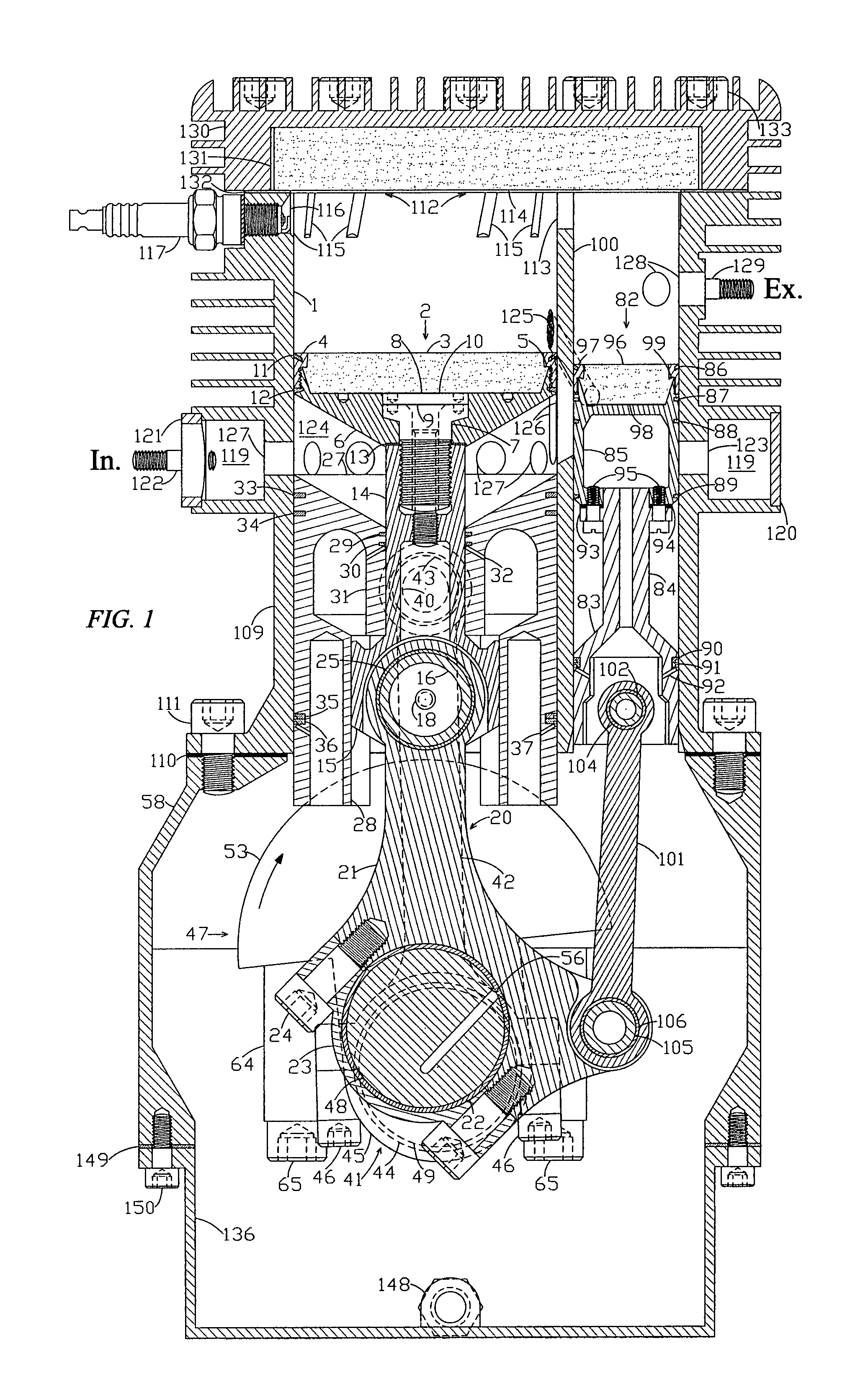

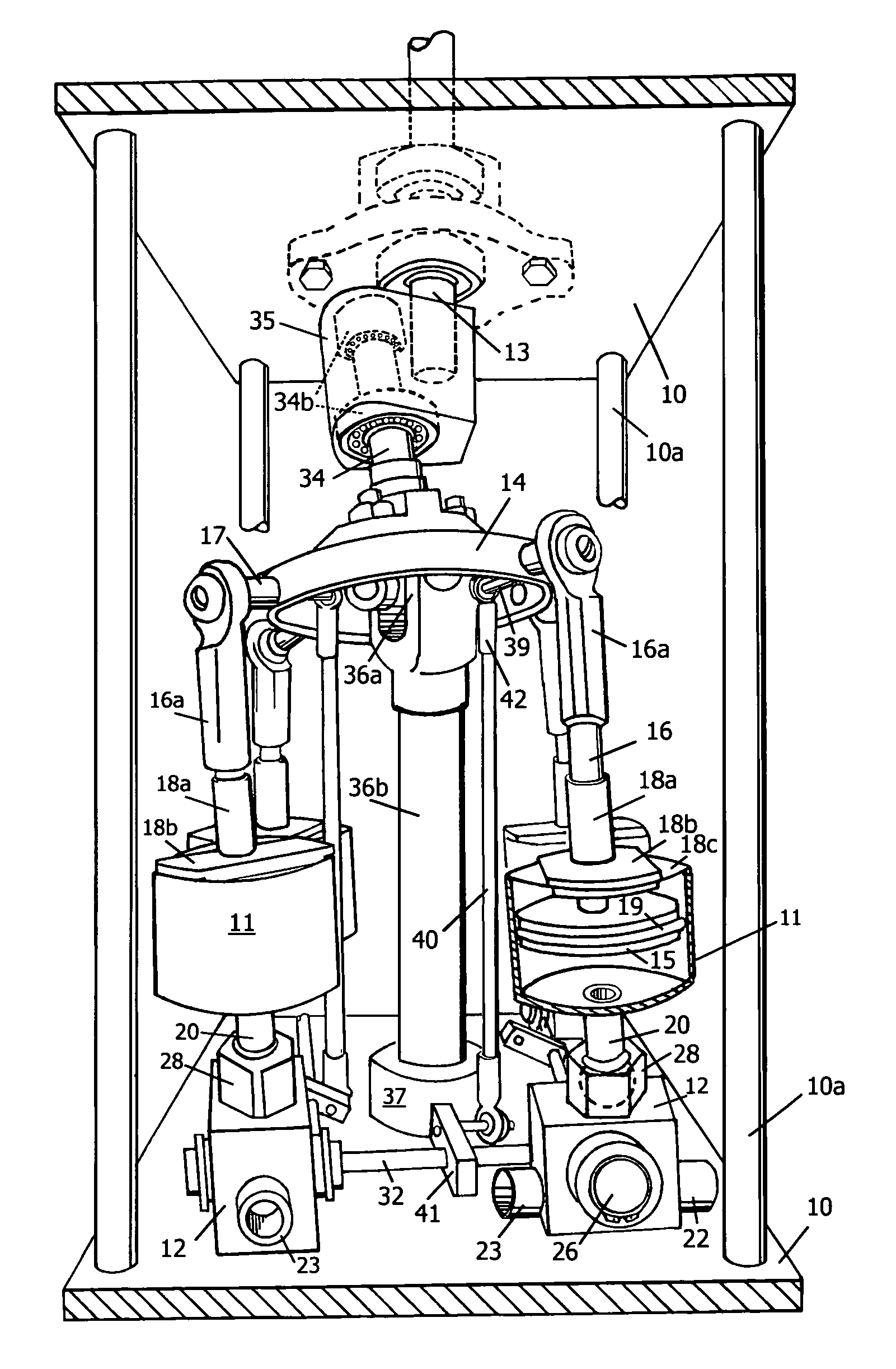

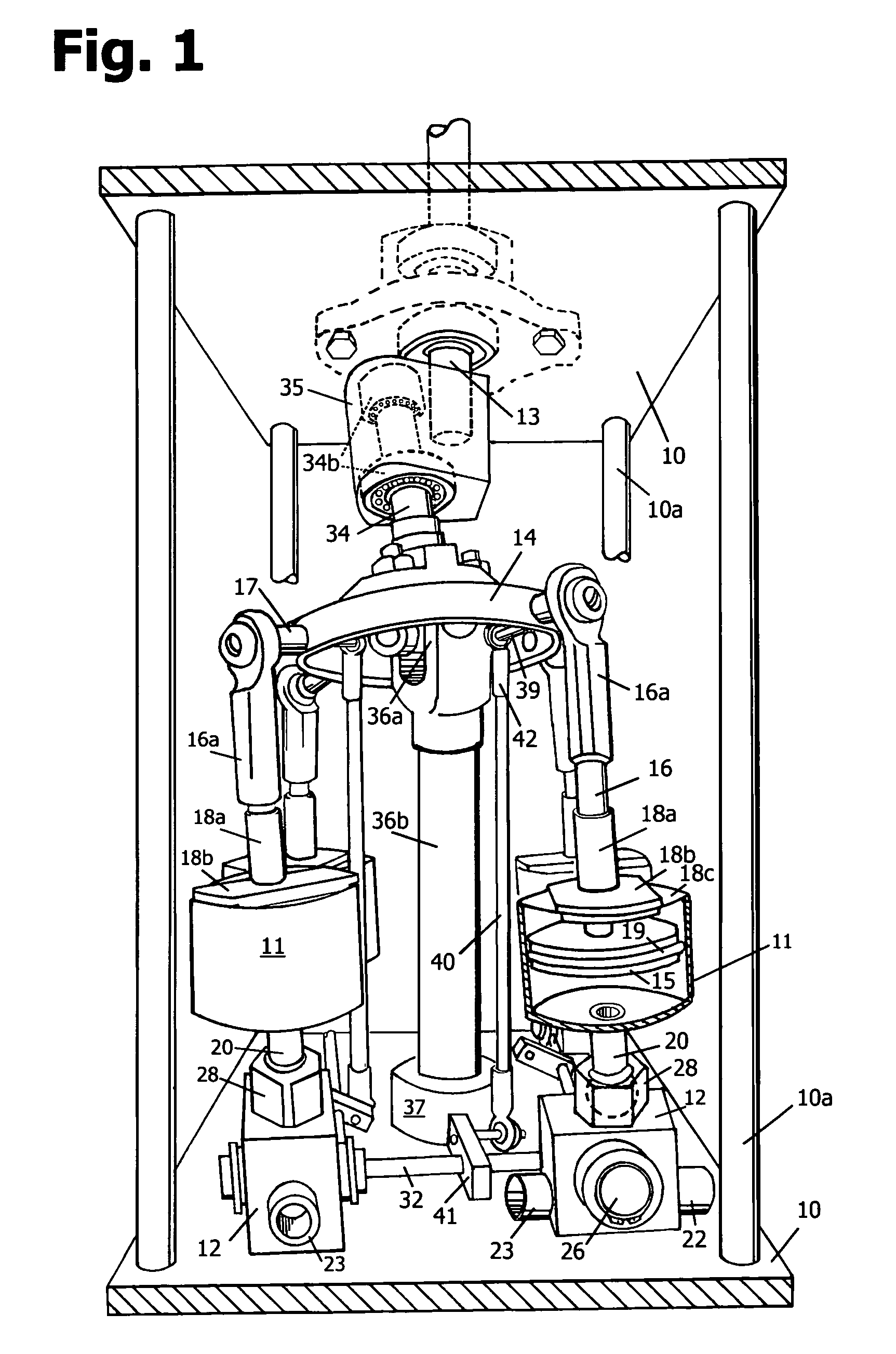

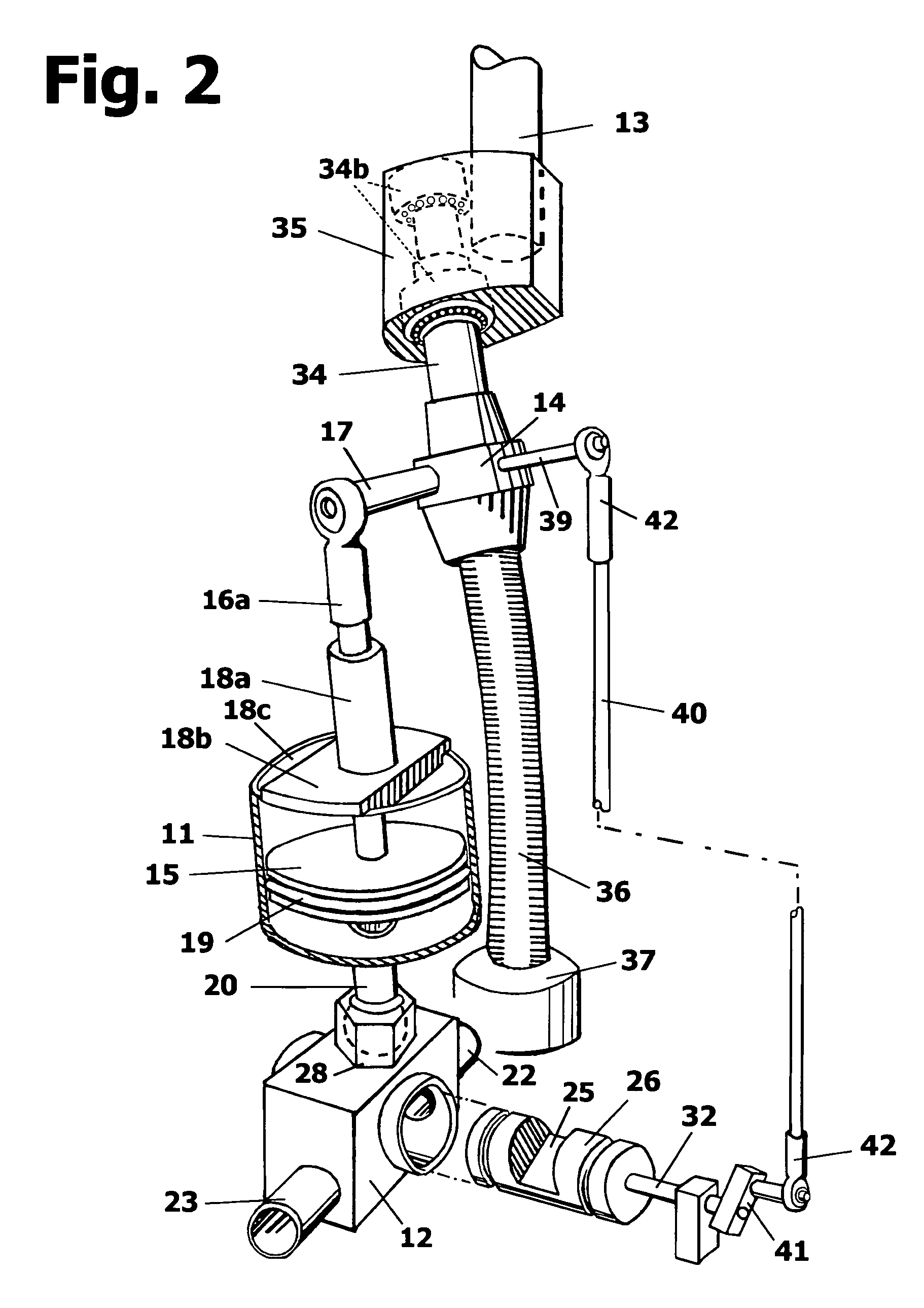

Straight-line piston fluid engine with wobble drive valve actuation

ActiveUS8096787B2Reduce weightEasily scalable for largeMulti-stage pumpsWobble plate gearingsControl valvesPiston

An axial piston fluid engine having single-acting cylinders incorporating swivel-joint attachment of the cylinders to rotary control valves wherein straight-line piston movement is established for the elimination of side forces on the pistons. The pistons and the control valves are operatively connected to a common wobble drive member and arranged in geometry of lever positions to coactively time the drive fluid into and out of the cylinders intermittently.

Owner:GREEN ROBERT R

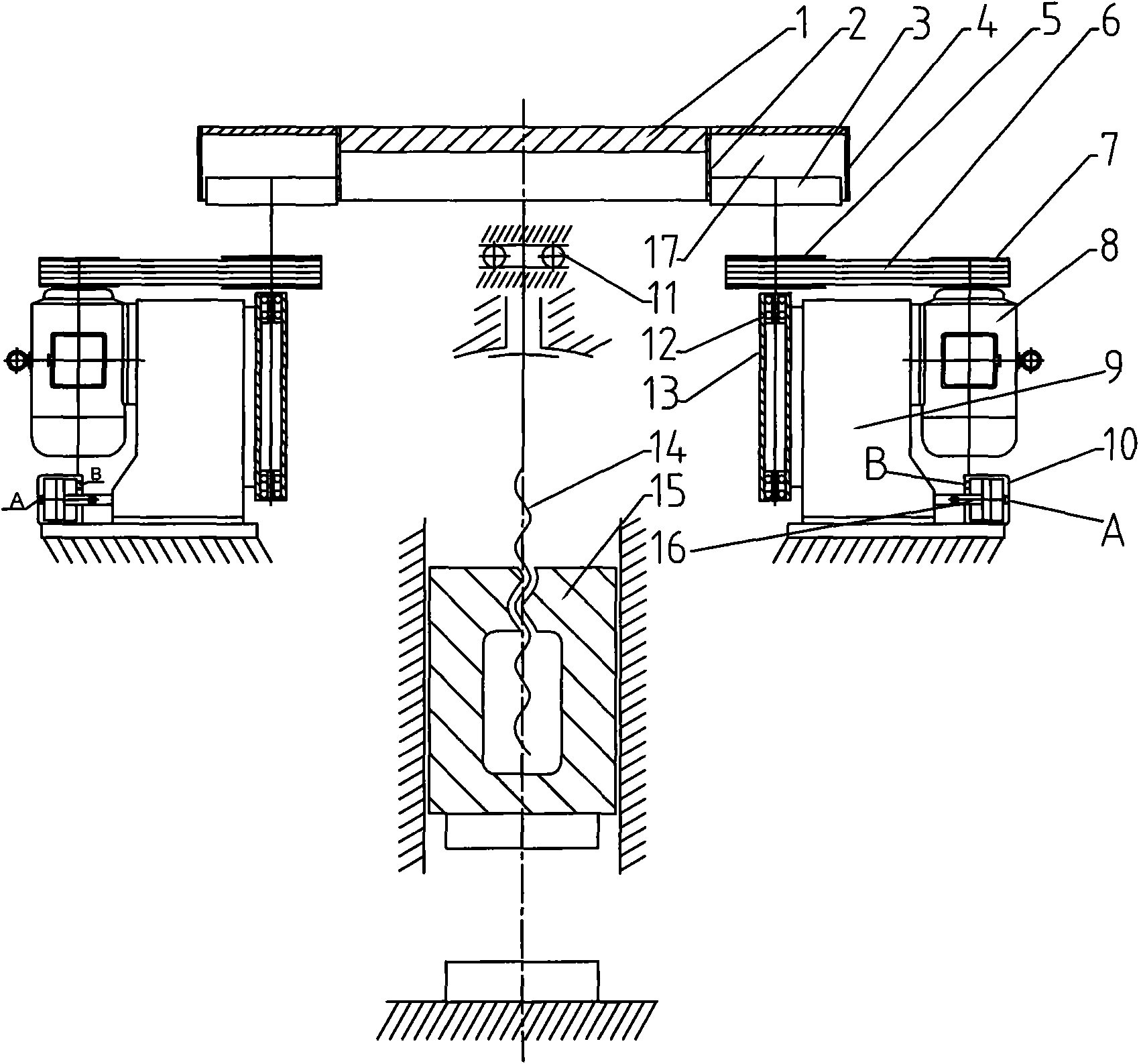

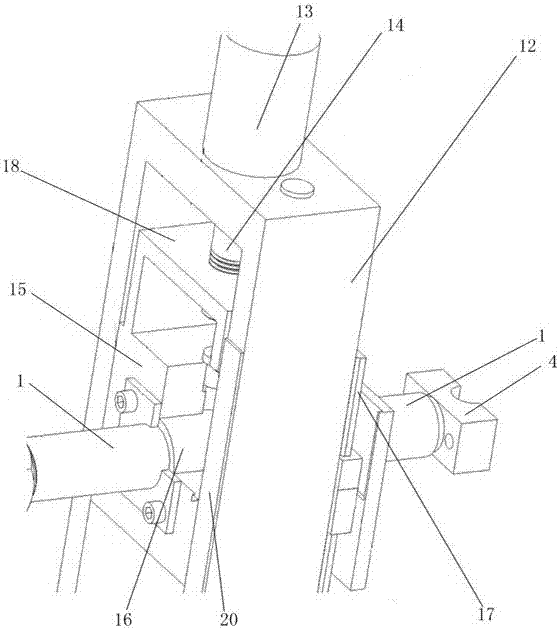

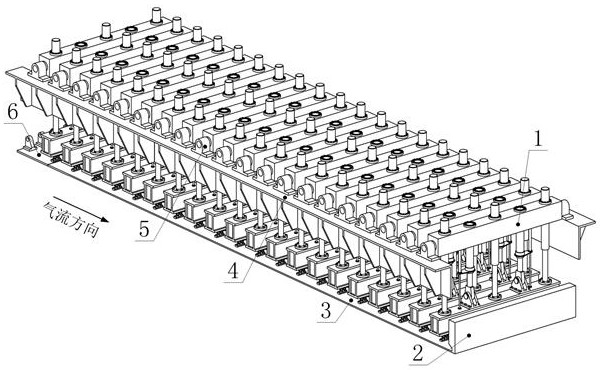

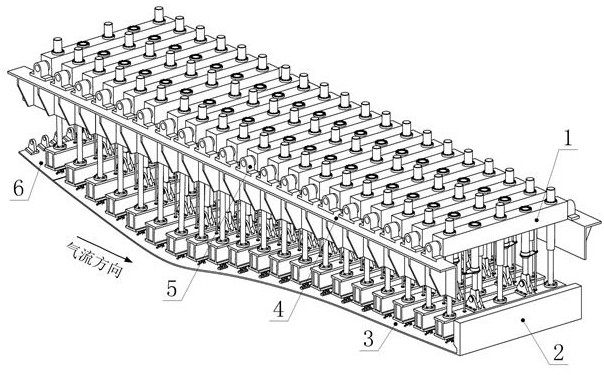

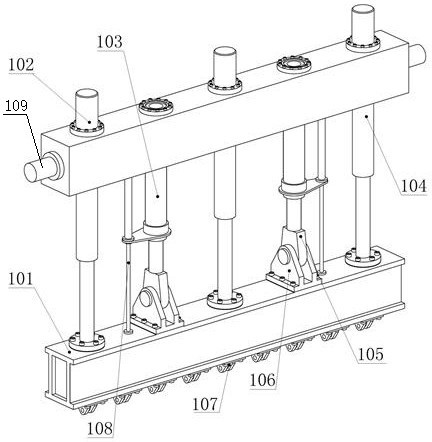

Hydraulic driving device applied to molded surface forming of wind tunnel nozzle

ActiveCN113049212AExtended service lifeImprove securityAerodynamic testingWind energy generationHydraulic ramMechanics

The invention discloses a hydraulic driving device applied to wind tunnel nozzle profile forming. The hydraulic driving device comprises a lower cross beam, an upper cross beam, a hydraulic driving mechanism, a guide mechanism, a spherical hinge hanging ring head, a push rod hinge base, a flexible plate hinge and a linear displacement sensor. The multiple hydraulic driving mechanisms and the multiple guiding mechanisms are symmetrically installed on the upper cross beam and connected with the lower cross beam, and the driving function and the guiding function are integrated. In the wind tunnel nozzle profile forming process, a plurality of hydraulic oil cylinders with small driving force can be combined into a large-load driving device required by accurate forming of a large wind tunnel nozzle, and the influence of lateral force on the oil cylinders is eliminated by utilizing the guide mechanism, so that large-load driving can be realized by utilizing the small hydraulic oil cylinders; and the reliability and the service life of the device are improved.

Owner:中国空气动力研究与发展中心设备设计与测试技术研究所

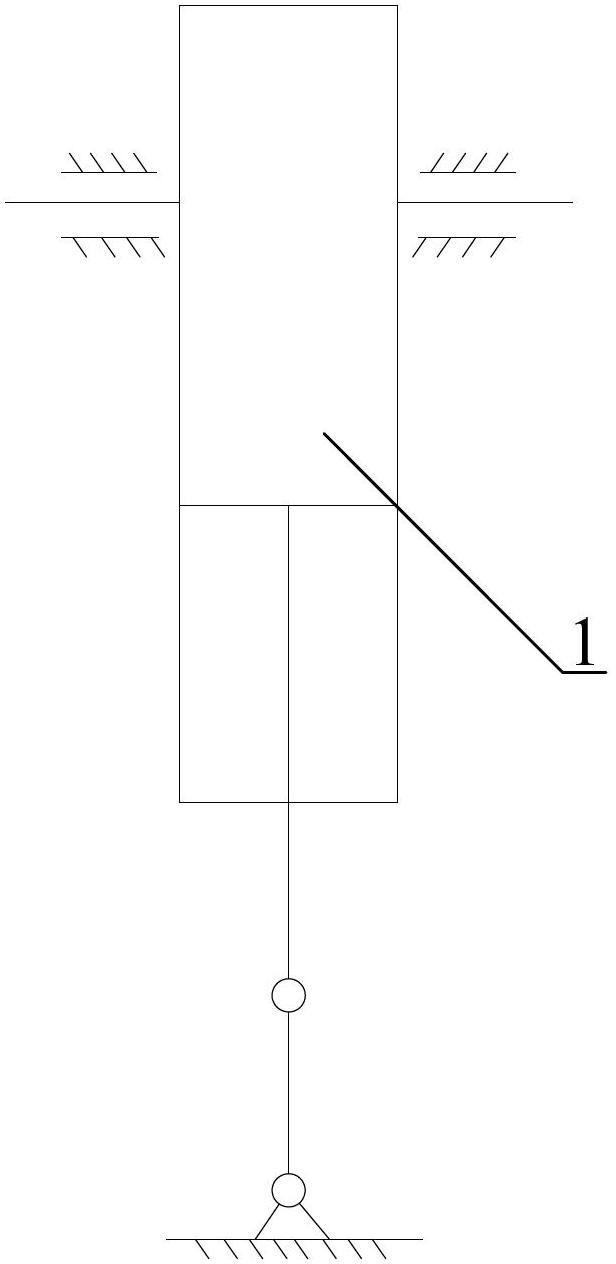

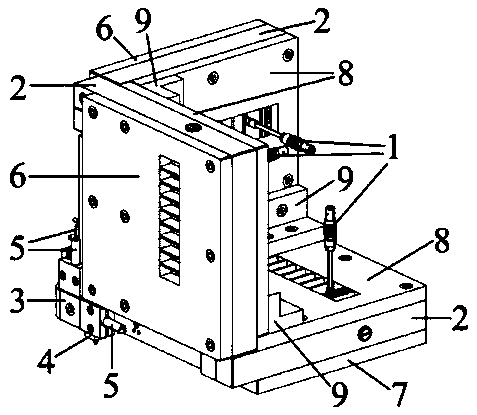

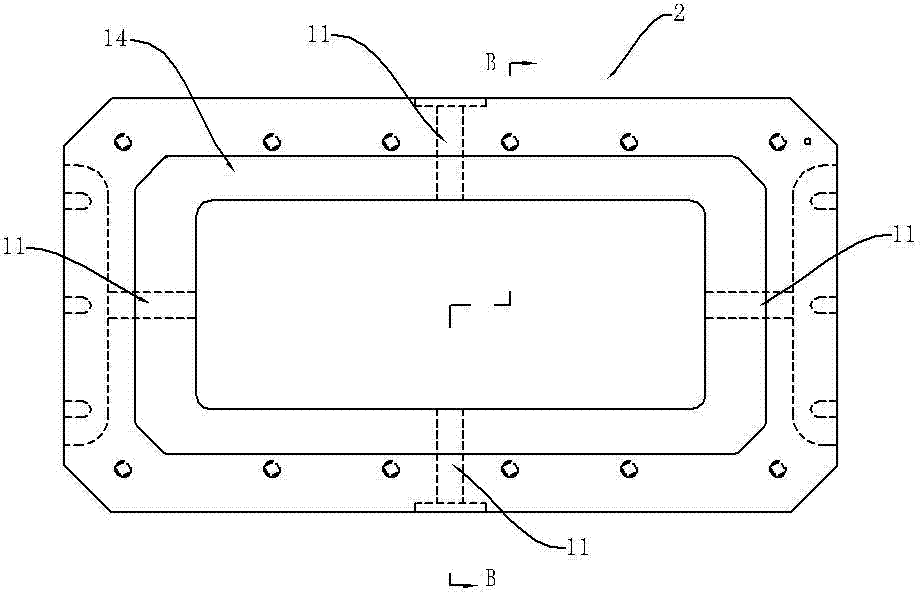

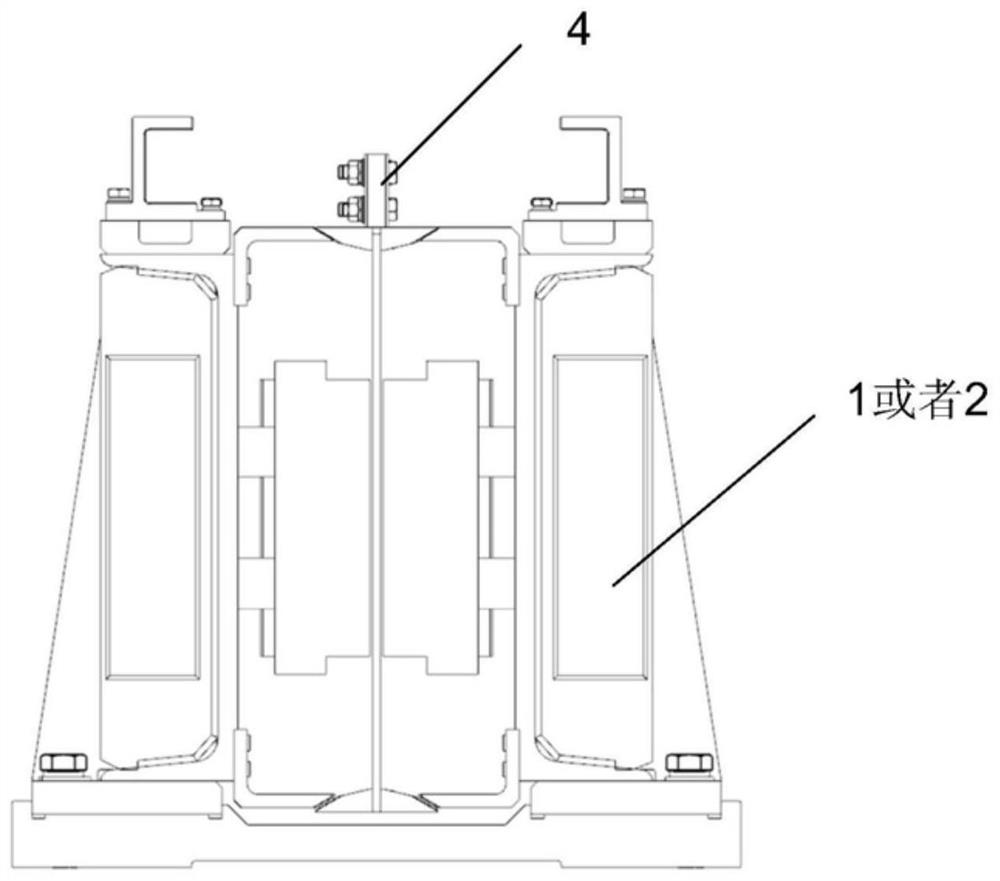

Mounting structure for forging die

ActiveCN104493047AEliminate lateral forceReliable lockingForging/hammering/pressing machinesLocking mechanismForging

The invention provides a mounting structure for a forging die, and aims to solve the problem that the forging die cannot be mounted and locked reliably as the forging die is directly mounted on a conventional die seat serving as a mounting structure through a wedge iron locking mechanism. The mounting structure comprises a die seat and the forging die, wherein the die seat comprises an upper die seat and a lower die seat; the forging die comprises an upper die and a lower die; the mounting structure is characterized in that the upper die and the lower die are mounted in the upper die seat and the lower die seat respectively through an upper die sleeve and a lower die sleeve; the upper die and the upper die sleeve as well as the lower die and the lower die sleeve are respectively in clearance fit; locking of the upper die and the lower die is realized between the upper die and the upper die sleeve as well as between the lower die and the lower die sleeve respectively through hanging pin structures.

Owner:WUXI TURBINE BLADE

Oil cylinder driven power set

InactiveCN102734055AImprove stabilityGreat driving forceReciprocating piston enginesHydraulic cylinderLow speed

The invention brings forward an oil cylinder driven power set, which comprises at least one hydraulic cylinder, a crankshaft and a fixed part. wherein the hydraulic cylinder comprises a cylinder, a piston and a piston rod. The cylinder is swingably arranged on the fixed part. The piston is fixedly connected with a first end of the piston rod. The crankshaft comprises a main journal and a rod journal, wherein the main journal is arranged on the fixed part; a second end of the piston rod is arranged on the rod journal, and the integral body forms a crank link mechanism to convert straight reciprocating motion of the piston rod into rotary movement of the crankshaft. According to the invention, the crankshaft is driven through hydraulic pressure to output rotary movement. The oil cylinder driven power set has advantages of large output torque, stationary operation, no offset load and overall stroke operation, is convenient to control, has a simple structure, is easy to implement, and is especially suitable for low-speed and large-torque application environment.

Owner:SANY HEAVY IND CO LTD (CN)

Turnout forging and pressing die

ActiveCN102554095AEasy maintenanceExtend your lifeRailway componentsForging/hammering/pressing machinesEngineeringMechanical engineering

The invention discloses a turnout forging and pressing die, comprising an upper die frame and a lower die frame, wherein the upper die frame and the lower die frame are buckled with a guide post by guide sleeves, an upper die sunk cavity is arranged on the upper die frame, an upper module is arranged in the upper die sunk cavity, a lower die sunk cavity is arranged on the lower die frame, a lower module is arranged in the lower die sunk cavity, and the upper module and the lower module are correspondent after the upper die frame and the lower die frame are buckled together; a drainage hole communicated with the lower die sunk cavity is arranged on the lower die frame; and an auxiliary module detaching device and a module fastening device are arranged between one end of the upper module and the upper die frame, a module fastening device is arranged between the side face of the upper module and the upper die frame, and module fastening devices are respectively arranged among one end of the lower module, the side face of the lower module and the lower die frame. According to the turnout forging and pressing die, the production efficiency is improved, the service life of the die is prolonged, and high production efficiency and convenience for change and maintenance are achieved.

Owner:常州明杰重工科技股份有限公司

High-speed linear electromagnetic propulsion and electromagnetic braking system

ActiveCN112671203AImprove power factorImprove efficiencyWindings insulation materialLaunching/towing gearElectricityElectric machine

The invention discloses a high-speed linear electromagnetic propulsion and electromagnetic braking system, belongs to the technical field of motors, and aims to solve problems that an existing unmanned aerial vehicle linear electromagnetic ejection system is poor in braking performance and low in reliability, cannot realize rotor resetting and the like. The system comprises a primary stage and a secondary stage. The primary stage comprises an electromagnetic acceleration section and an electromagnetic braking section; the electromagnetic acceleration section and the electromagnetic braking section share the secondary stage, and the secondary stage is a rotor; the electromagnetic acceleration section is composed of an armature for driving the coreless linear permanent magnet synchronous motor; the electromagnetic braking section is composed of an eddy current braking conductor plate and a braking coreless linear permanent magnet synchronous motor armature. The secondary stage is composed of the secondary stage and the middle secondary stage arranged up and down or the secondary stage and the middle secondary stage arranged left and right, and each secondary stage comprises a secondary yoke plate and a permanent magnet. The high-speed linear electromagnetic propulsion and electromagnetic braking system is used for electromagnetic catapulting.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com