Hydraulic-drive combined land preparation machine

A drive type, soil preparation technology, applied in soil preparation machinery, agricultural machinery and implements, shovels, etc., can solve the problems of high power consumption, difficulty in breaking soil, and soil compaction and stickiness, etc., to achieve high work efficiency, convenient head turning, The effect of high crushing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

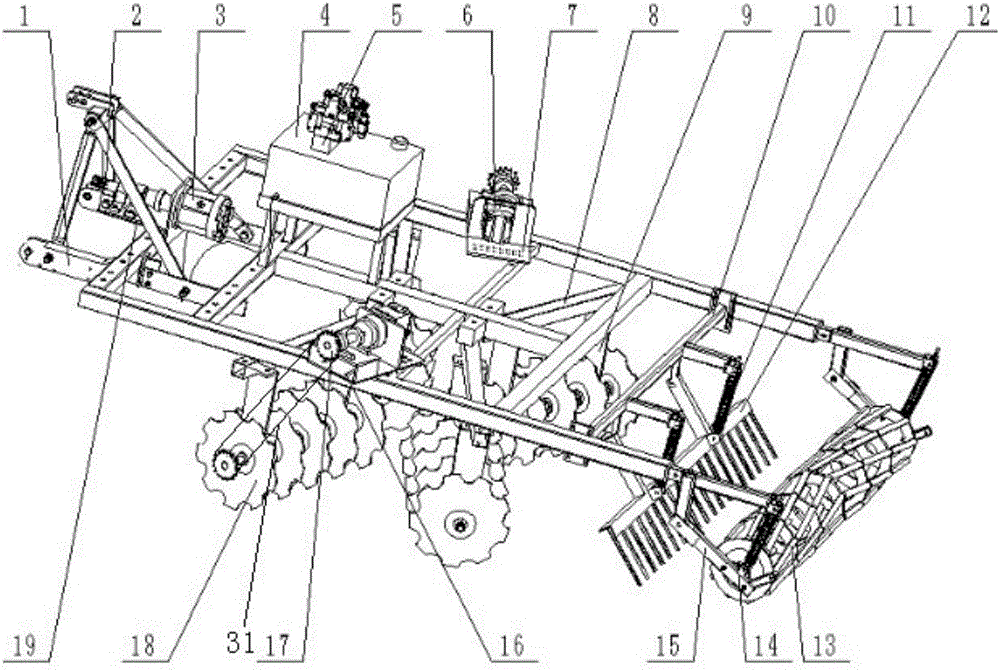

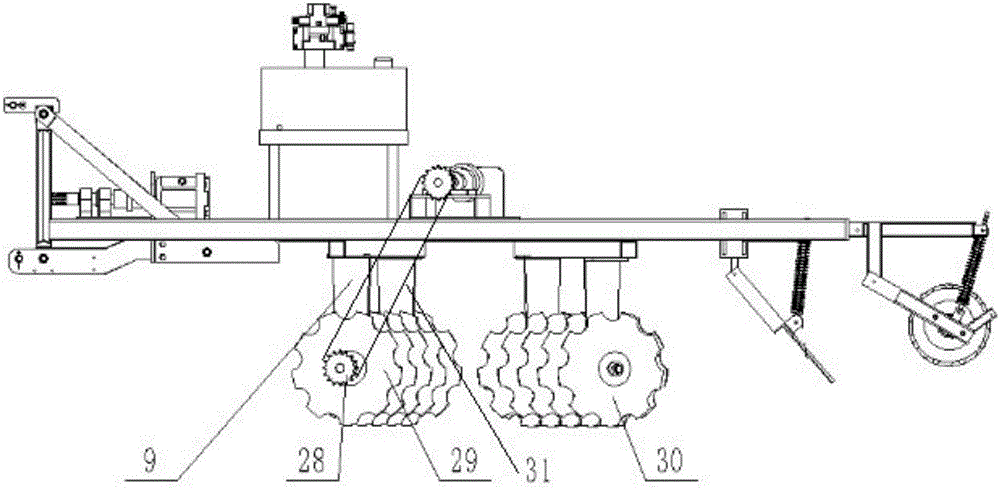

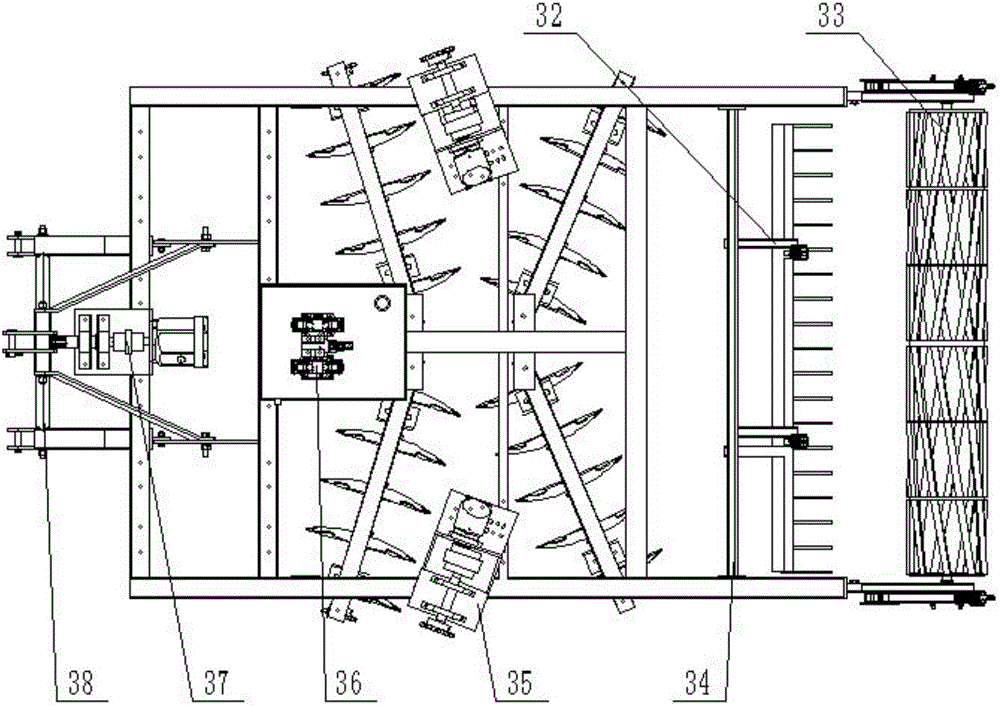

[0018] Embodiment: A hydraulically driven combined land preparation machine of the present invention includes a main body frame 1, a leveling rake unit 10 and a suppression unit 13, and also includes a hydraulic drive unit 5 and a notch disc unit 18. The main frame 1 includes Right beam 20, the left beam 26 that arranges in parallel with right beam 20, the first crossbeam 27 that two ends are respectively fixed on right beam 20 and left beam 26, the second crossbeam 25, motor support beam 22 and the 3rd crossbeam 23, two Ends are respectively fixed on the vertical beam 24 between the second beam 25 and the third beam 23 and the three-point suspension frame 38 fixed on the first beam 27 and the second beam 25, and the motor support beam 22 is located on the second beam 25 and the third crossbeam 23; the hydraulic drive unit 5 includes a hydraulic motor 6 provided with a first sprocket 17, an input shaft base 19 fixed on the first crossbeam 27, a power input mounted on the input ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com