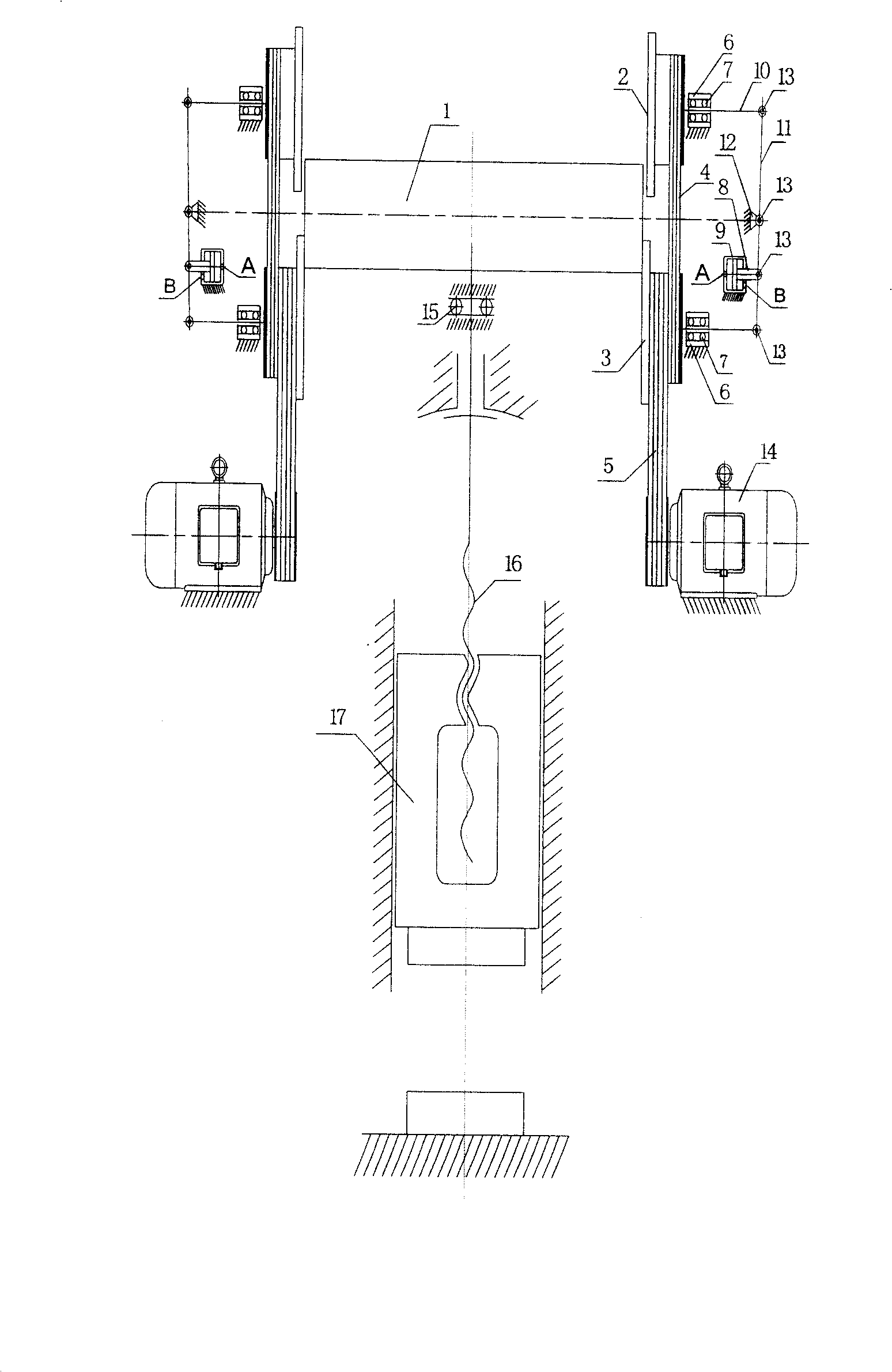

Drive mechanism of four-wheel friction screw press

A technology of screw presses and drive mechanisms, used in presses, punching machines, manufacturing tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

[0010] See the driving mechanism of the four-wheel friction screw press shown in the accompanying drawing, which has a horizontally rotating flywheel 1, the flywheel 1 is fixedly connected with the screw rod 16, and is connected to the bed through the plane bearing 15 (see the part indicated by the oblique line in the figure, attached All parts represented by slash lines in the figure are bed) rotation connection, flywheel 1 is left-handed or right-handed by the effect of friction wheel, and screw rod 16 drives slider to move up and down to implement forging operation, which is the difference between the present invention and the prior art. place. The difference is that an upper friction wheel 2 and a lower friction wheel 3 are arranged symmetrically on both sides of the flywheel 1 in the present invention. Because the structures on both sides are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com