Drum-type friction screw press

A technology of screw press and drum type, applied in the direction of presses, stamping machines, manufacturing tools, etc., can solve the problems of cost copper nut wear, large-scale development of presses, and reduce the efficiency of transmission machinery, etc., to prolong the service life and eliminate side force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

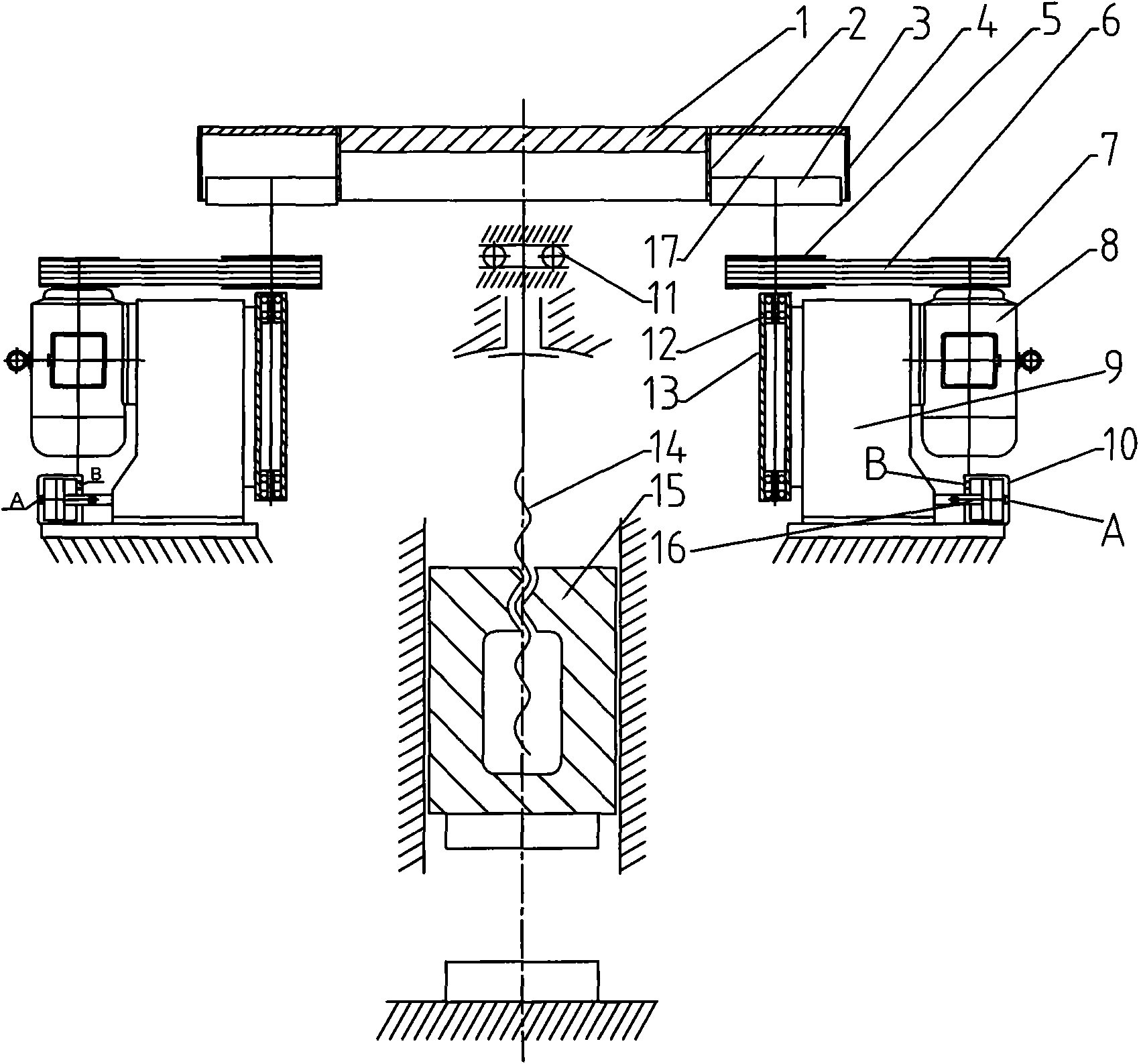

[0022] Such as figure 1 As shown, the drum type friction screw press includes a machine base 9, a horizontally rotating flywheel 1, the flywheel 1 is fixedly connected with the screw rod 14, and is rotationally connected with the machine base 9 through a plane bearing 11, the slider 15 is threadedly connected with the screw rod 14, and the slider 15 moves in the vertical direction, the flywheel 1 is rotated left or right by the action of the friction wheel 3, and the screw rod 14 drives the slider 15 to move up and down to implement the forging operation. An annular cavity 17 is provided inside the flywheel 1 , and the inner and outer walls of the cavity 17 respectively form the inner rim 2 and the outer rim 4 of the flywheel 1 . The cavity 17 is not closed, and an opening is provided below. Friction wheels 3 are arranged radially symmetrically in the cavity 17 , and there may be two, four, or eight friction wheels 3 . . . the number depends on the size of the flywheel 1 . T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com