Fiber filtering component with honeycomb wall cross section structure

A technology of fiber filtration and cell wall, applied in sustainable biological treatment, water/sludge/sewage treatment, biological water/sewage treatment, etc. Unsatisfactory state and other problems, achieve good economic benefits, eliminate short flow and dead angle, and improve volumetric efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

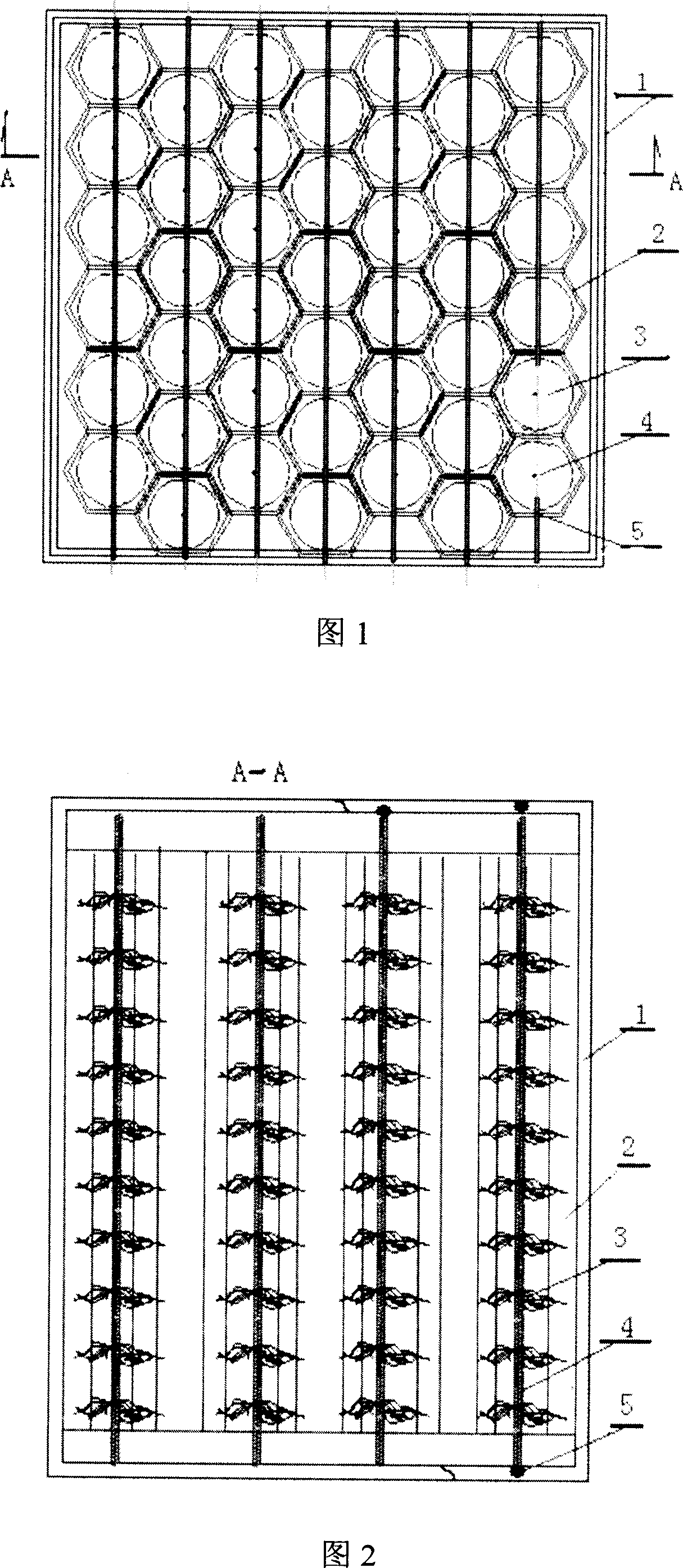

[0014] Embodiment: have the fibrous filter member of honeycomb cell wall section structure, external framework structure 1 is made of engineering plastics, and size is high 1.7m * 1.0m * 1.0m, and its height is 1.7m; Honeycomb cell wall 2 material is polypropylene, The diameter of the inscribed circle of the hexagonal cross-section is Ф100mm, and the height of the honeycomb pipe section is 1.5m; the semi-soft fiber filter material 3 is worn inside the honeycomb pipe, and the diameter of the fiber cluster is Ф100mm, which is suspended in series with the central rope 4, and the distance between the clusters of the fiber filter material is 60mm . The crosspieces 5 are arranged in parallel, and are reinforced by adding a support beam at the midpoint perpendicular to the crosspieces through the hexagonal centroid of the honeycomb. The filter material of the present invention is used as a filler for a gas lift alternating circulation flow filter tank. The water depth of the filter ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com