Straight-line reciprocating piston type compressor

A linear reciprocating, piston-type technology, applied in the field of compressors, can solve the problems of increased power consumption, poor sealing performance, and increased overall size of the compressor, and achieve the effects of improved work efficiency, small vibration, and small friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

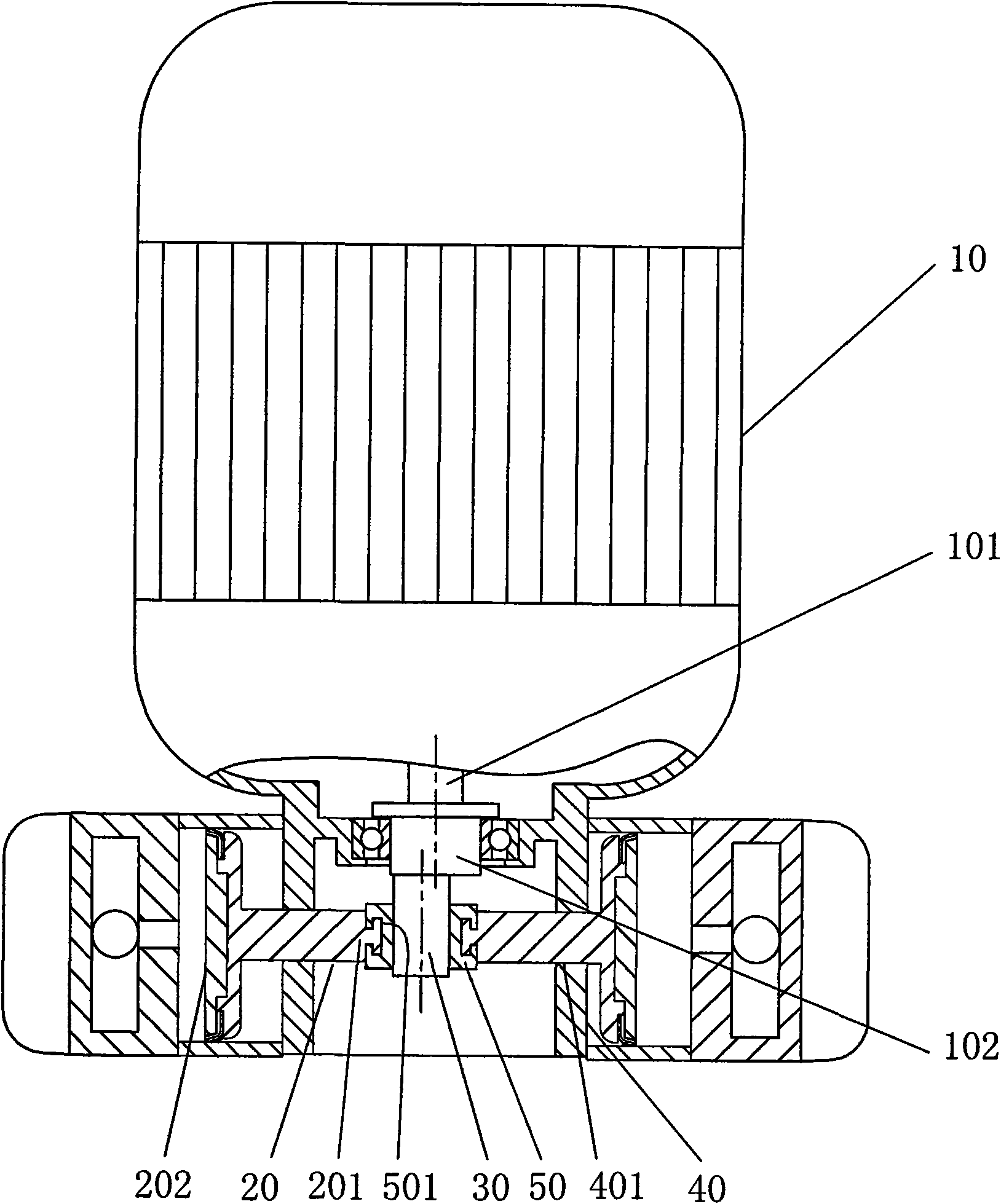

[0046] Example 1, see Figure 1-2 :

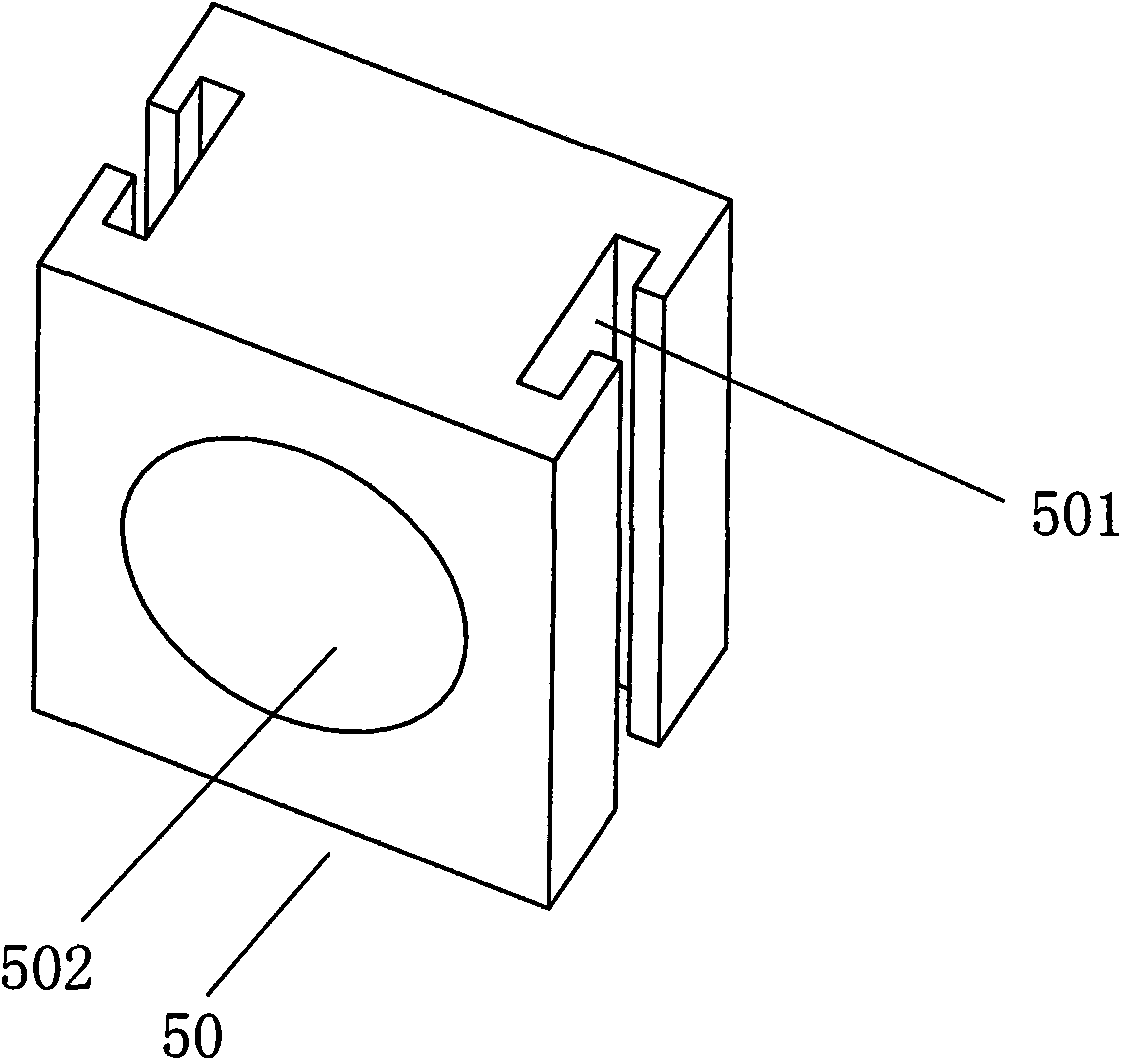

[0047] The structure of the linear reciprocating piston compressor includes a motor 10, a crankcase 40, a crankshaft 30, a piston rod 201, a cylinder, and an intake and exhaust device. The main shaft 102 of the motor 10 is directly connected to the crankshaft 30, and one end of the piston rod 20 is provided with a The piston part 202 is provided with a piston rod 20 with a force transmission part 201 at the other end, and the force transmission part 201 of the piston rod 20 is connected with the outer guide rail 501 of the slider 50, and the middle part of the slider 50 is provided with a bearing hole matched with the crankshaft 30 502, the crankshaft 30 is set in the bearing hole 502 of the slider 50, the above-mentioned crankcase 40 is provided with the motion guide structure 401 of the piston rod 20, the above-mentioned piston part 202, the piston rod 20 and the matching cylinder and the intake and exhaust There are two sets of devices...

Embodiment 2

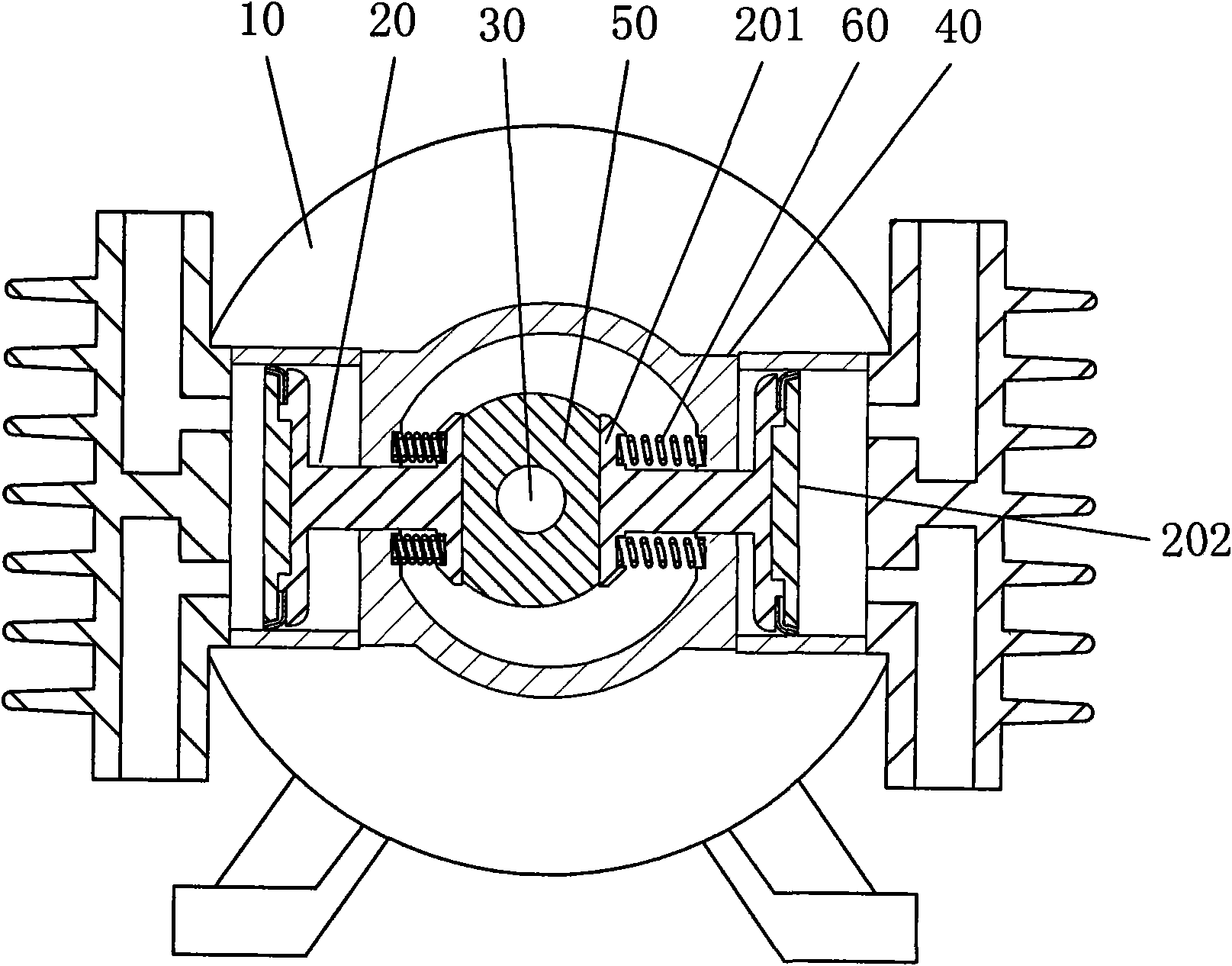

[0048] Example 2, see image 3 :

[0049] The structure of embodiment 2 is basically the same as that of embodiment 1, the difference being that a slide block 50 is set on the crankshaft 30, between the force transmission part 201 of the piston rod 20 and the crankcase 40 in the direction of movement of the piston rod 20 A spring 60 is arranged between them, and the spring 60 presses the slider 50 and the force transmission part 201 of the piston rod 20 so that the force transmission part 201 of the piston rod 20 and the slider 50 always keep zero-distance contact.

Embodiment 3

[0050] Embodiment 3: see Figure 4 and image 3 :

[0051] The structure of embodiment 3 is basically the same as that of embodiment 2, the difference is that a number of friction-reducing needle rollers 70 are arranged between the slider 50 and the force transmission part 201 of the piston rod 20, and the needle rollers 70 can reduce friction. Frictional force between the slider 50 and the force transmission part 201 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com