Intermediate-speed large-torque radial plunger hydraulic motor

A technology of hydraulic motor and high torque, applied in the field of medium-speed and high-torque radial piston hydraulic motors, can solve the problems of poor processability, fluctuation of output torque of crankshaft 3, poor positioning ability of connecting rod 6, etc. Efficiency and reliability, reduced friction and heat generation, good effect on neutrality and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0113] In order to make the technical features, objectives and beneficial effects of the present invention clearer, the specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

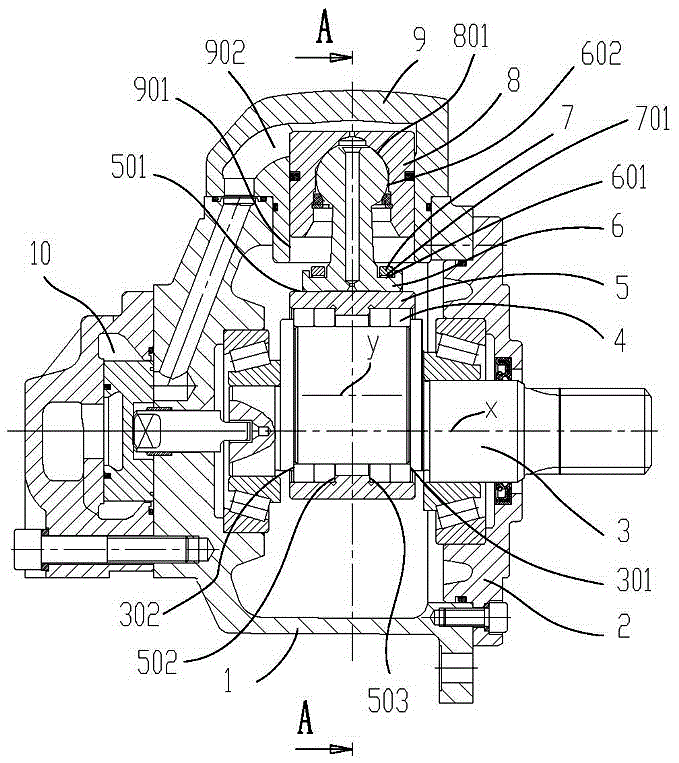

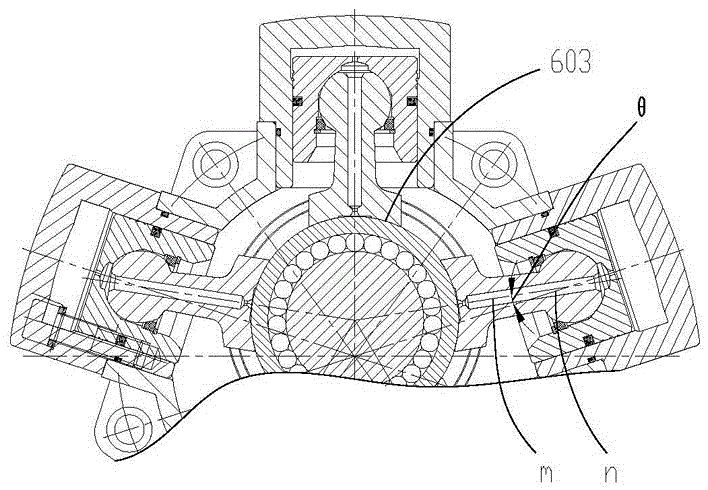

[0114] Such as Figure 8 As shown, a medium-speed high-torque radial plunger hydraulic motor includes a housing 1, a crankshaft 2 for outputting rotational speed and torque to the outside, a bearing 29 arranged in the inner hole of the housing 1 and the front cover 27, and the outer casing is eccentrically mounted on the crankshaft 2. The roller 3 of the shaft section 201, the roller 3 is sleeved in the inner hole 401 of the bearing sleeve 4, radially star-shaped and uniformly fastened to the cylinder head 5 of the housing 1, distributed radially along the bearing seat 4 and the upper and lower ends The telescopic sleeve 6 that is respectively offset against the outer spherical surface 501 of the cylinder head 5 and the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com