Four-wheel friction screw press

A technology of screw press and friction wheel, which is applied to the driving device of forging press and other directions, can solve the problems of increasing power loss, cost copper nut wear, and increased friction between thread teeth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

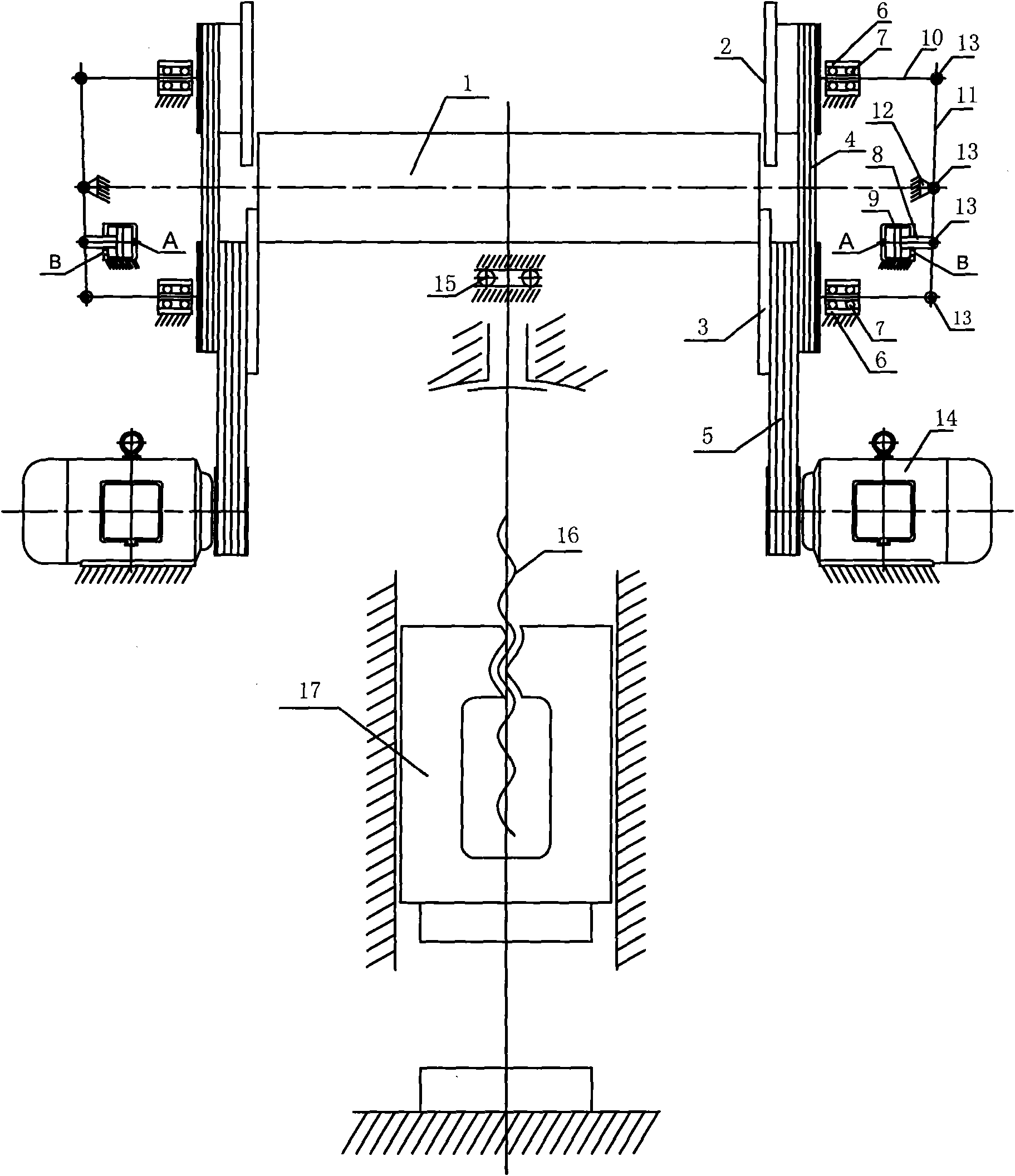

[0016] Below in conjunction with accompanying drawing, the implementation of technical scheme is described in further detail:

[0017] See attached figure 1 The driving mechanism of the shown four-wheel friction screw press has a horizontally rotating flywheel 1, the flywheel 1 includes a hub, and the outer surface of the hub is equipped with a friction edge, and the friction edge includes an upper friction edge 100 and its The opposite lower friction edge 200 is installed around the hub.

[0018] The flywheel 1 is fixedly connected with the screw rod 16, and is rotationally connected with the bed through the plane bearing 15. The flywheel 1 rotates left or right under the action of the friction wheel, and the screw rod 16 drives the slider to move up and down to carry out the forging operation. This is the difference between the present invention and the prior art. the same. The difference is that an upper friction wheel 2 and a lower friction wheel 3 are arranged symmetric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com