Opposed gas bearing linear compressor

A technology of linear compressors and gas bearings, applied in the field of linear compressors, can solve the problems of high vibration and noise and difficulty in assembling compressor moving parts, achieve low vibration and noise, eliminate inertia matching problems, and reduce assembly difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing:

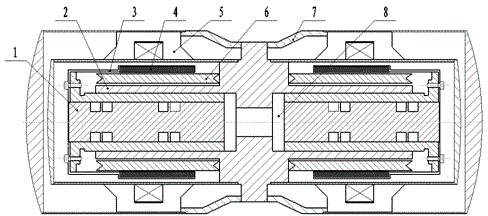

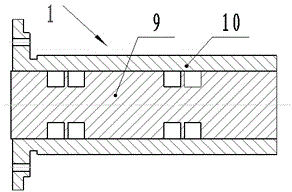

[0021] like figure 1 The shown opposed gas bearing linear compressor includes a cylinder 2, two opposed pistons 1 disposed inside the cylinder, and two opposed linear motors disposed outside the cylinder 2.

[0022] The cylinder 2 is provided with a compression chamber 8 inside, and two pistons 1 are located on both sides of the compression chamber 8 . The pistons 1 on the same side of the compression chamber 8 are in one-to-one correspondence with the linear motors. Driven by the corresponding linear motors, the two pistons 1 make synchronous reciprocating linear motions in opposite directions along the axial direction of the cylinder 2 . During the synchronous reciprocating linear movement of the two opposed distributed pistons along the axial direction of the cylinder, the working flow introduced into the compression chamber will be compressed.

[0023] The linear moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com