Lifting mechanism for PC assembly type concrete part

A concrete and prefabricated technology, applied in cranes, transportation and packaging, load hanging components, etc., can solve the problems of low flexibility and inconvenient movement of the device, and achieve the effect of improving the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

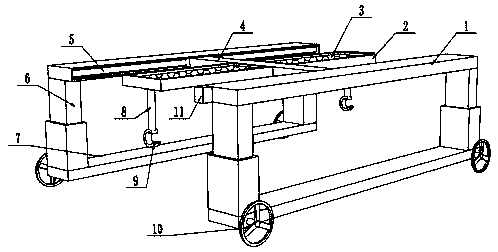

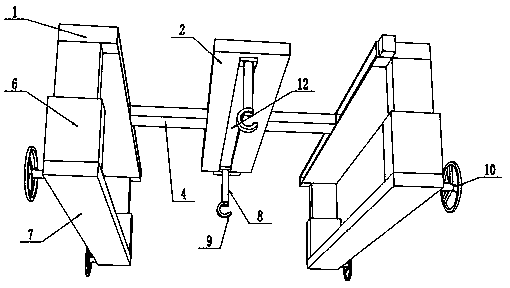

[0028] Reference Figure 1-2 , A lifting mechanism for PC-assembled concrete components, including a supporting mechanism, a lifting mechanism, and a hanging mechanism; the supporting mechanism includes two bottom plates 7 and two top plates 1, and both sides of the bottom plate 7 are fixed by axles There is a wheel body 10 to facilitate the transfer of the device and adapt to the lifting of concrete structures in different locations; the lifting mechanism includes four hydraulic cylinders 6, and the four hydraulic cylinders 6 are respectively fixed on the two corners of the tops of the two bottom plates 7, four The hydraulic cylinder 6 is connected to a synchronous hydraulic system. One end of the piston rod of the hydraulic cylinder 6 is fixed to the bottom end of the top plate 1. The hanging mechanism includes a connecting column 4 and a connecting frame 2, and the top of the connecting frame 2 is provided with a groove, and the groove is Embedded with solar panels 3, which ...

Embodiment 2

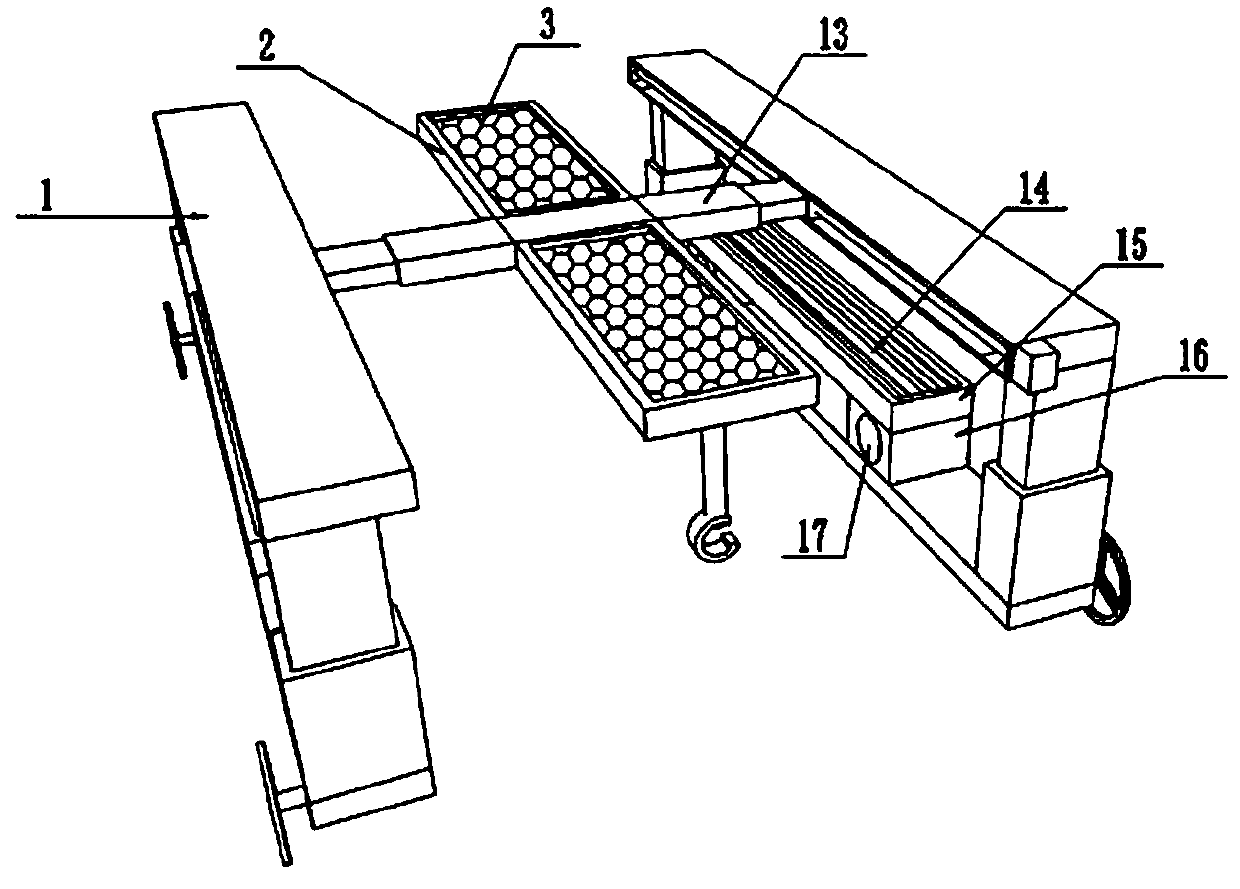

[0032] Reference image 3 , A lifting mechanism for PC-assembled concrete components. Compared with the first embodiment, this embodiment replaces the connecting column 4 with the second hydraulic cylinder 13, and the two hydraulic cylinders 13 are connected with a synchronous hydraulic system; The hydraulic cylinder 13 adjusts the distance between the two bottom plates 7 to meet different specifications of product hoisting; at the same time, the two sides of the top of the bottom plate 7 are welded with a connecting seat 16, and the side wall of the connecting seat 16 is provided with a hole 17 for two connections The top of the seat 16 is fixed with the same storage box 15 by screws, and a number of movable rods 14 are placed in the storage box 15; the movable rods 14 can be inserted into the socket 17, forming a supporting component at the bottom end to avoid the lifting process The phenomenon of falling and breaking of middle concrete components occurred.

[0033] Working pri...

Embodiment 3

[0035] Reference Figure 4 , A lifting mechanism for PC-assembled concrete members. Compared with Example 1 and Example 2, this embodiment has a counterweight box 18 fixed by screws on both sides of the top of the base 7, and the counterweight box 18 can be placed The counterweight can avoid the phenomenon of heavy equipment and tipping during hoisting.

[0036] Working principle: connect the device to the mobile power supply; move the device to a proper position through the wheel body 10, the hydraulic cylinder 6 adjusts the hook 9 to the proper position, and the electronically controlled slide rail 12 works to adjust the distance between the two hooks 9 and passes the second hydraulic pressure The cylinder 13 adjusts the distance between the two top plates 1 and lifts the concrete member through the hook 9; inserts into the socket 17 through the connecting column 14 to play a bottom support role; when the equipment is heavily weighted, it is placed in the counterweight box 18 T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com