Canopy surface structure of front canopy used for mine excavation

A technology of the front beam and beam surface, which is applied to support the top beam of the mine roof, mining equipment, earthwork drilling and mining, etc., and can solve the problems of limited bearing capacity of the front beam, impact on support performance, and limited support capacity , to achieve the effect of improving the supporting capacity, improving the supporting effect, and improving the supporting capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

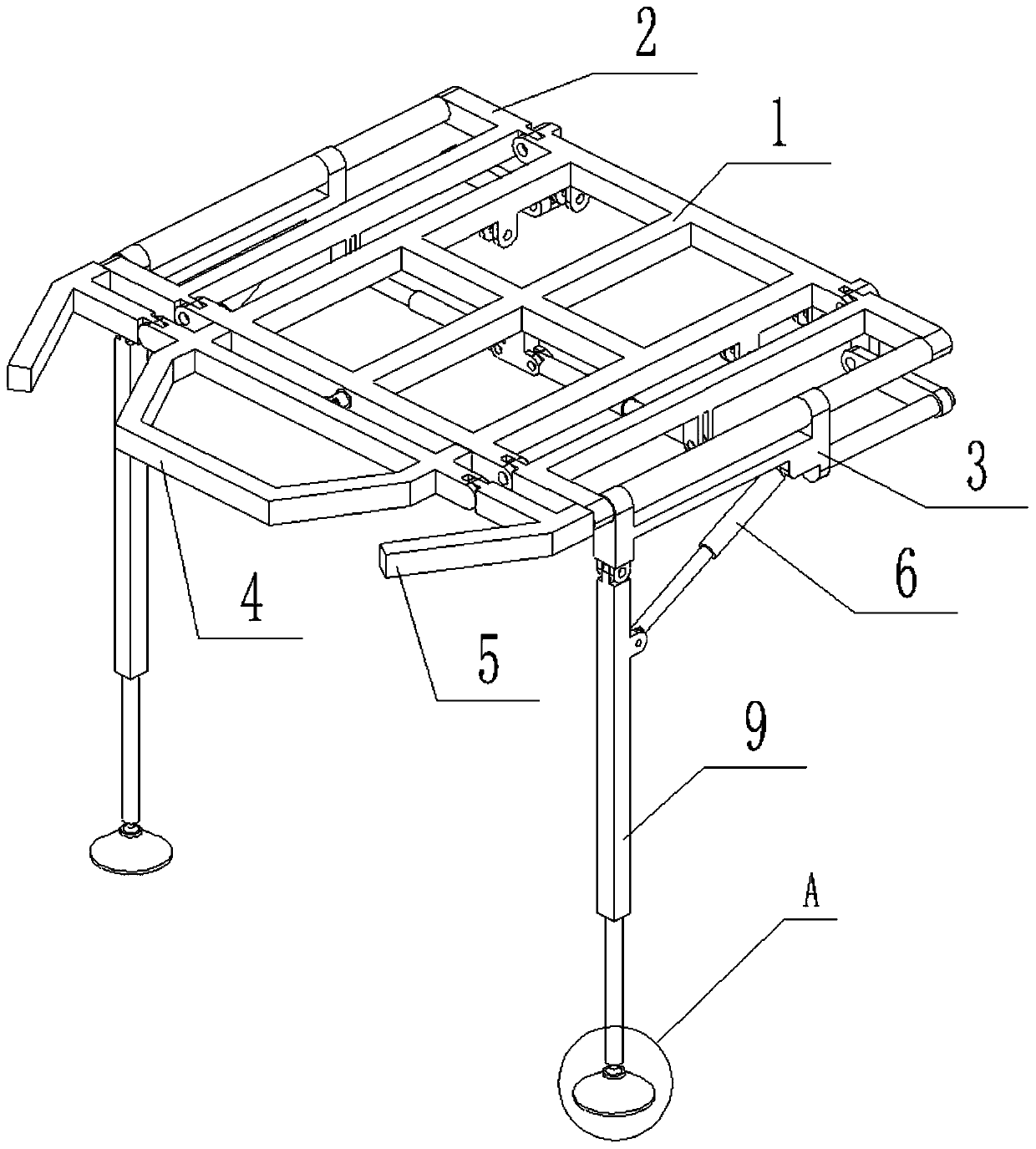

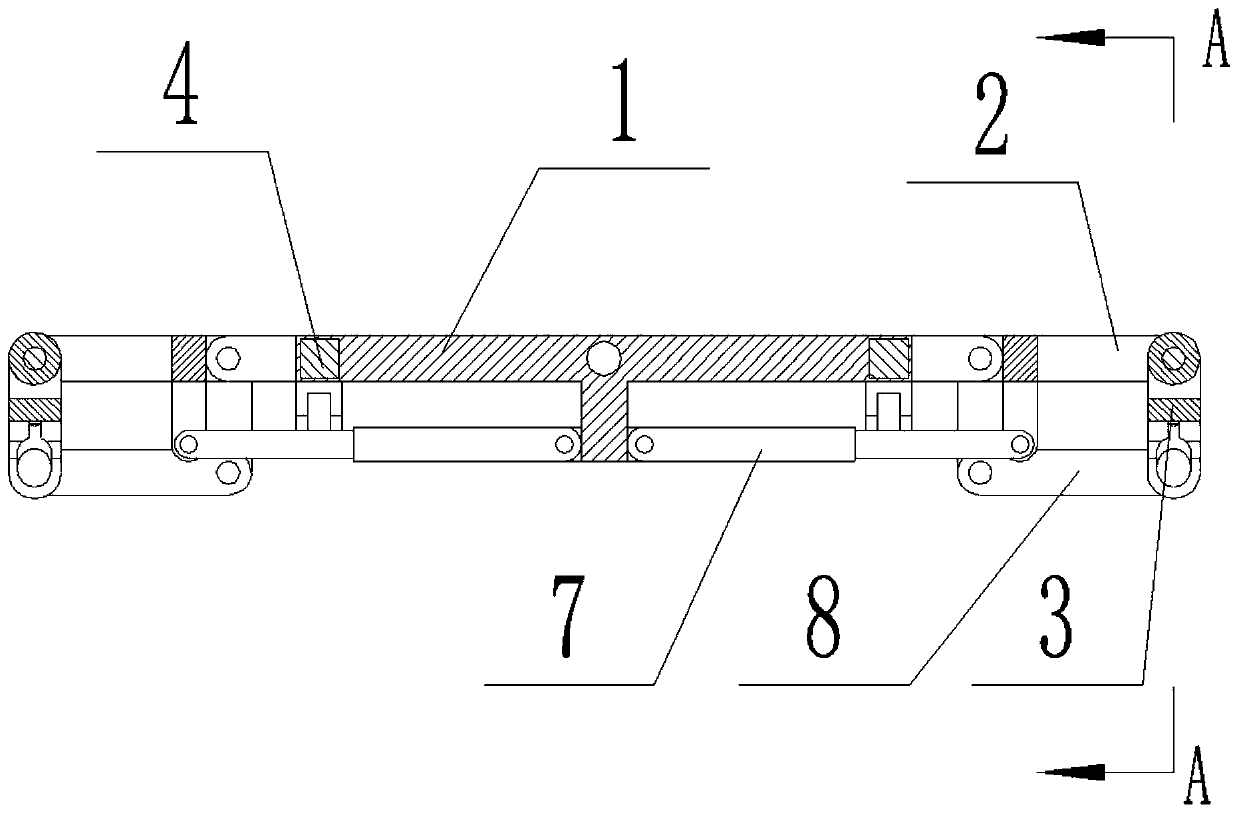

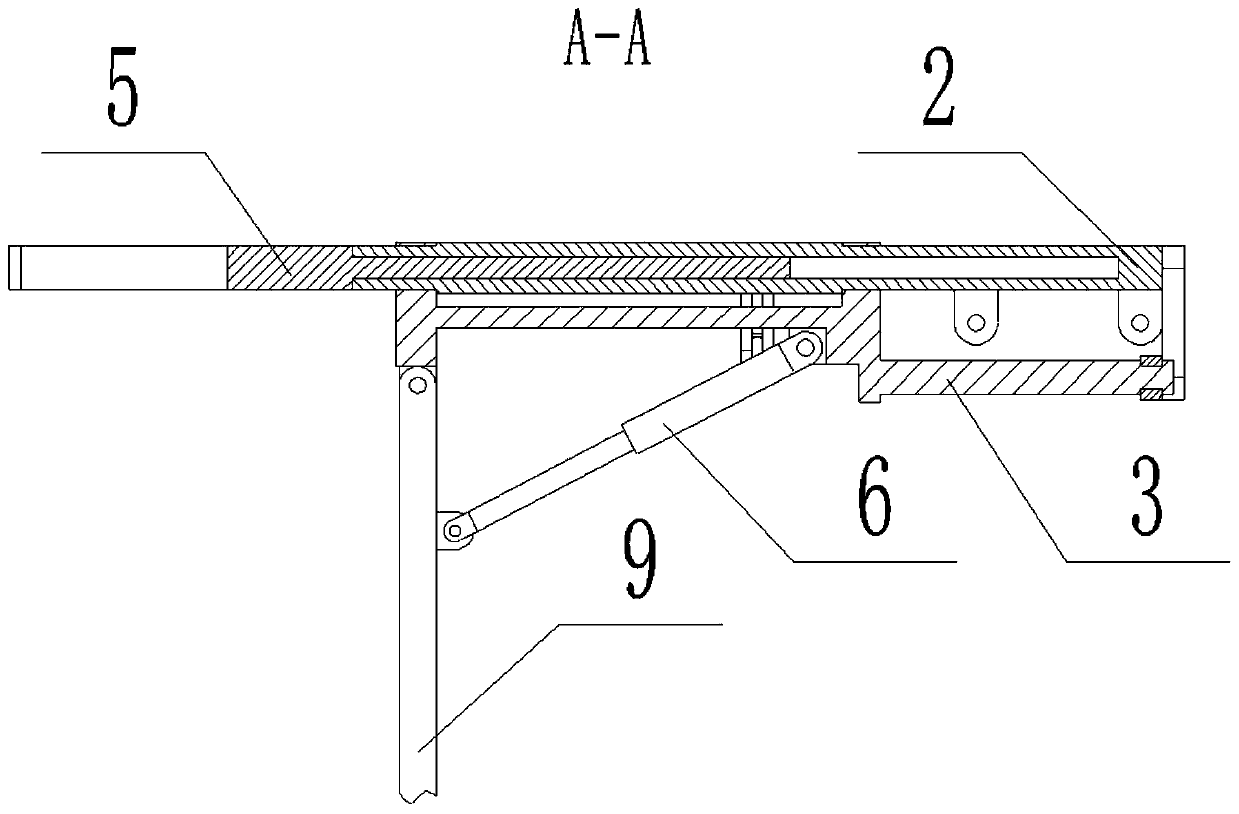

[0030] as attached figure 1 to attach Figure 8 Shown:

[0031] The present invention provides the beam surface structure of the front probe beam used for coal mine excavation, including: main beam surface 1, swing side beam 2, journal 201, sliding hole 202, outrigger frame 3, telescopic beam 4, sliding square rail 401, Telescopic side beam 5, sliding circular rail 501, outrigger hydraulic cylinder 6, swing hydraulic cylinder 7, connecting rod 8, supporting leg 9 and telescopic hydraulic cylinder 10; a group of telescopic beams 4 are slidably connected to the front end of main beam surface 1; A set of swing side beams 2 are hinged on the left and right sides of the beam surface 1; a set of telescopic side beams 5 is slidably connected to the front end of the swing side beam 2; a set of outrigger frames 3 are hinged on the outer side of the swing side beam 2; The bottom of the frame 3 is hinged with a set of support legs 9; the support legs 9 and the outrigger frame 3 are con...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap