Safety clutch of anchor windlass and control method thereof

A technology of a safety clutch and a control method, which is applied in the field of windlass safety clutch and its control, which can solve problems such as the disengagement of the clutch from the anchor chain wheel and the failure of the clutch to disengage normally, so as to prevent the main shaft from torque overload bending, long service life, and stable operation. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

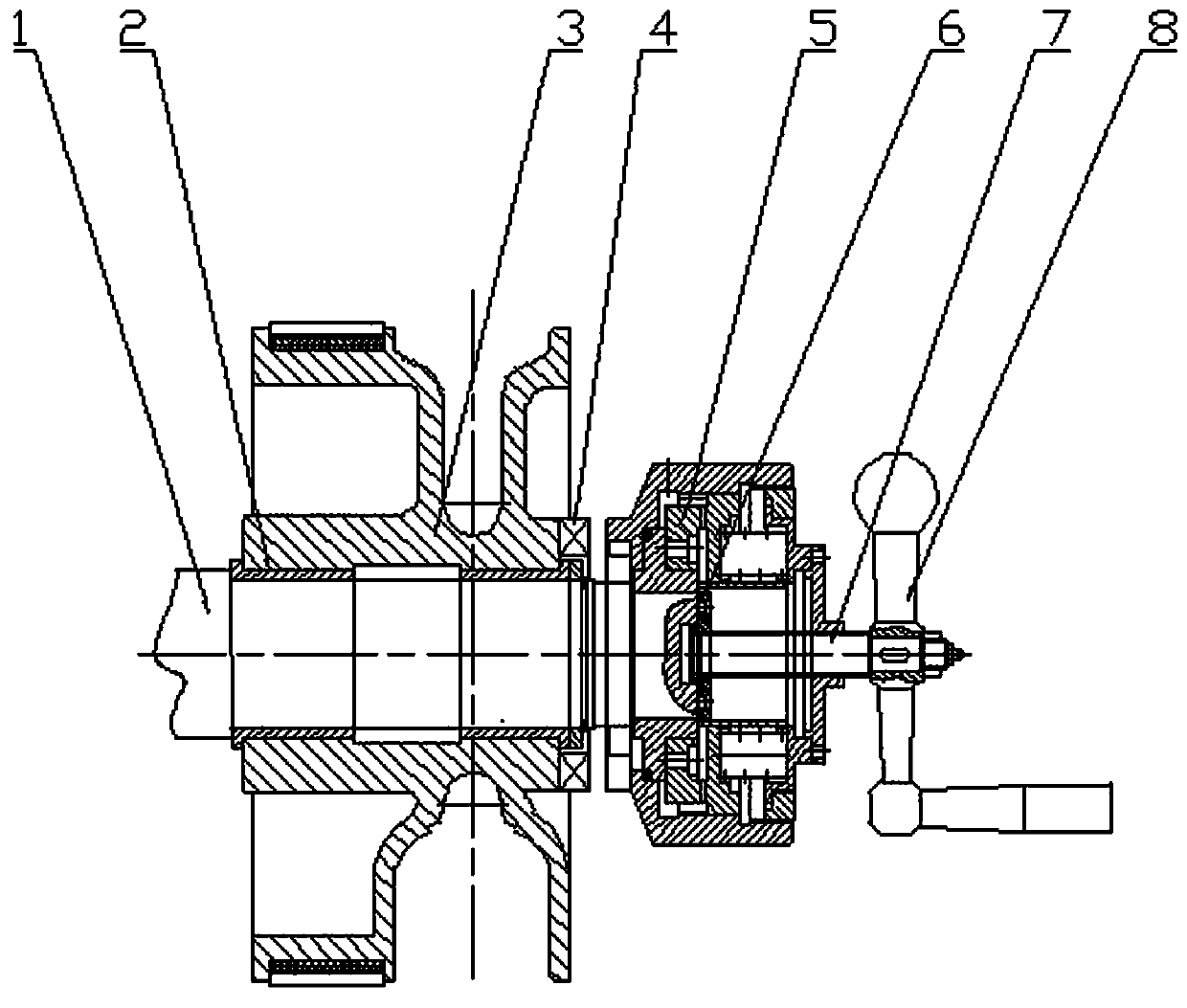

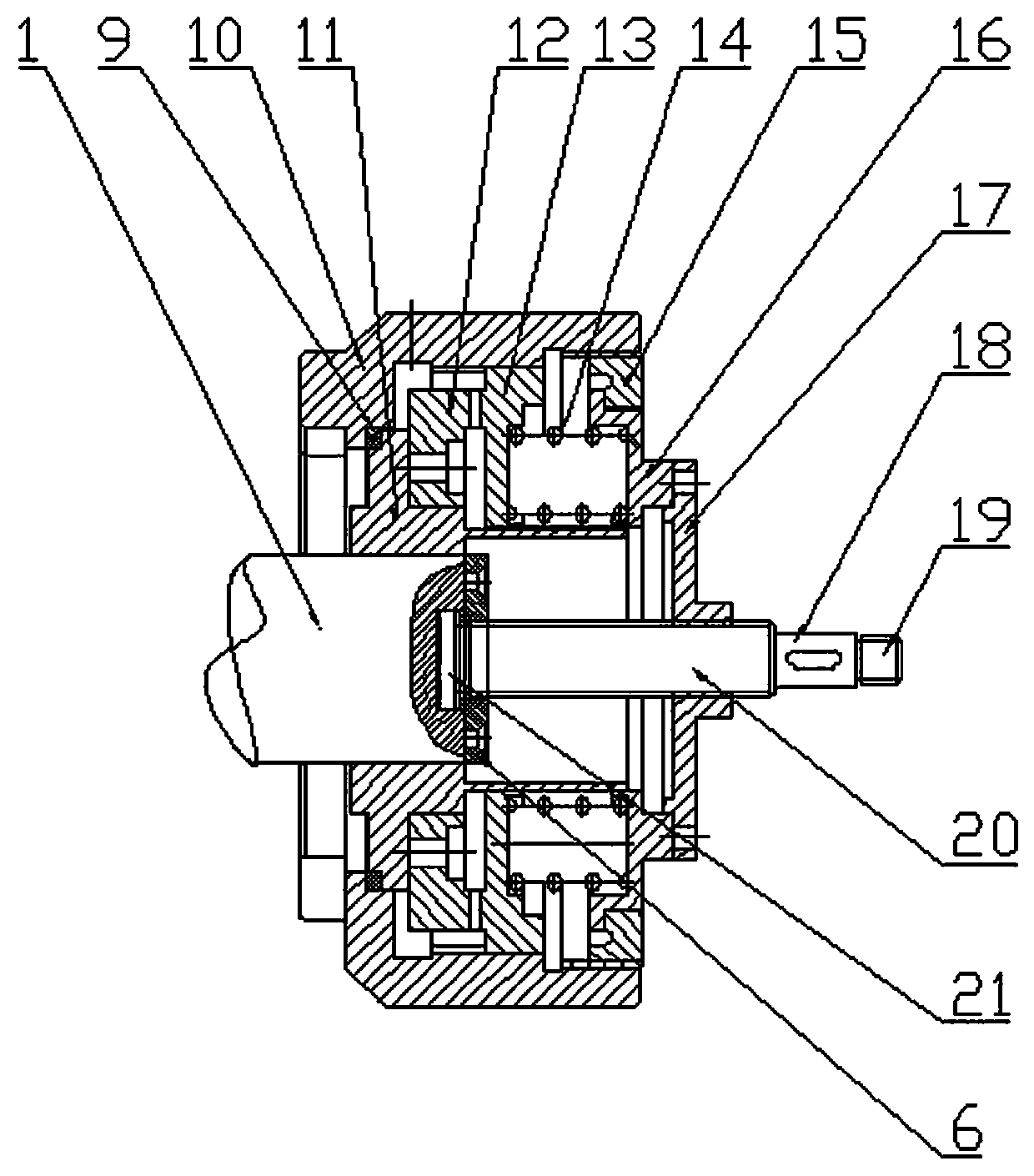

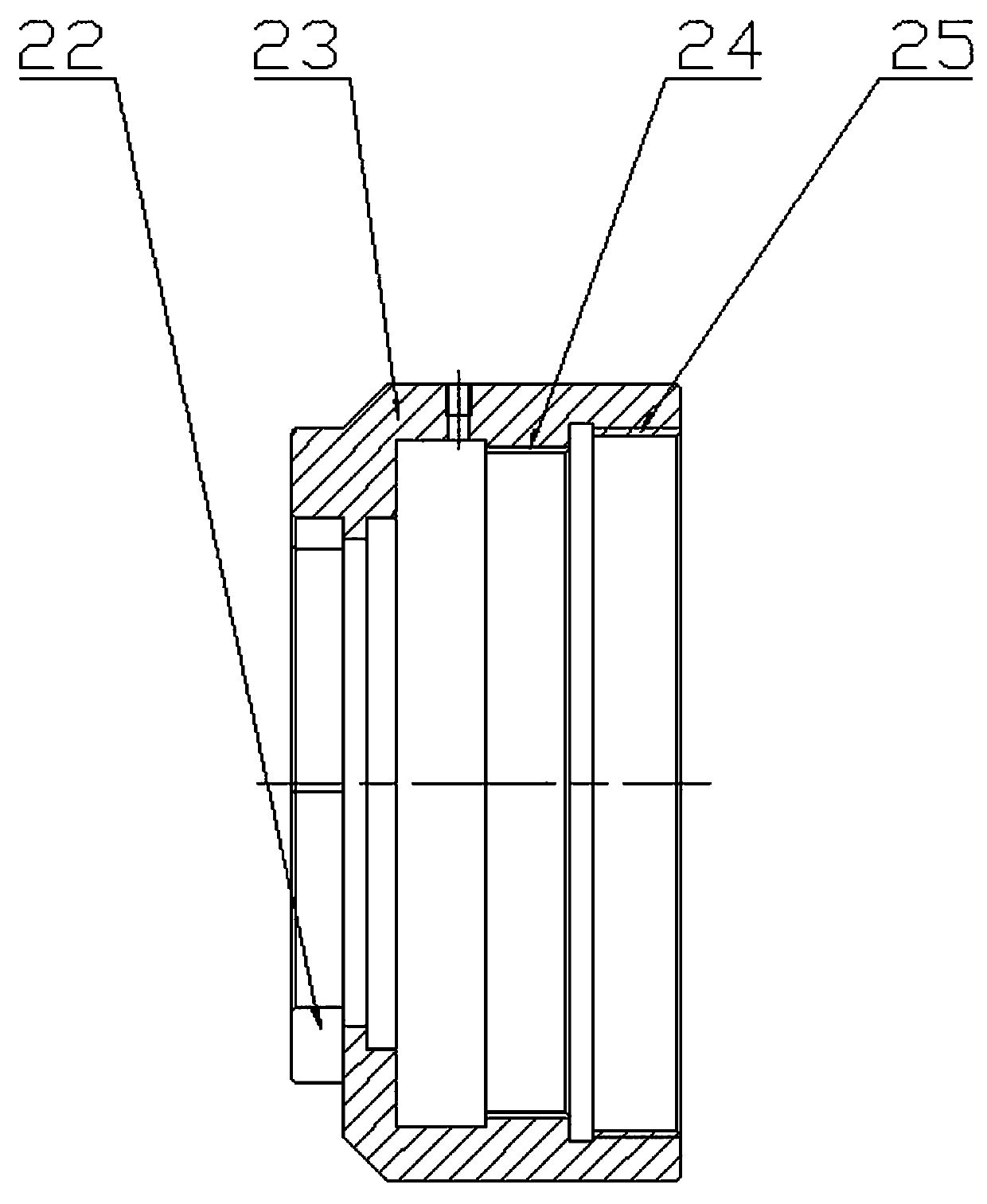

[0028] Example: such as Figure 1-5As shown, a windlass safety clutch includes an anchor chain wheel 3, and the anchor chain wheel 3 is provided with a main shaft 1 socketed with the anchor chain wheel 3, and a pair of mirror-like symmetry is arranged between the main shaft 1 and the anchor chain wheel 3. The distributed shaft sleeve 2, the main shaft 1 is provided with the clutch assembly 5 which is in active engagement with the anchor chain wheel 3, and the anchor chain wheel integrated with the anchor chain wheel 3 is provided between the clutch assembly 5 and the anchor chain wheel 3 Tiger claw 4, the clutch assembly 5 is provided with a clutch handwheel shaft 7 that is socketed with the main shaft 1, and the clutch handwheel shaft 7 includes a clutch screw 20, and the clutch screw 20 and the main shaft 1 are provided with the main shaft 1 and the clutch screw 20 is a screw limiting disc 21 with an integrated coaxial center structure, and the clutch screw 20 is threadedly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com