Measurement device of large roller datum surface run-out numerical value

A technology of measuring device and datum, applied in the direction of measuring device, mechanical measuring device, using mechanical device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

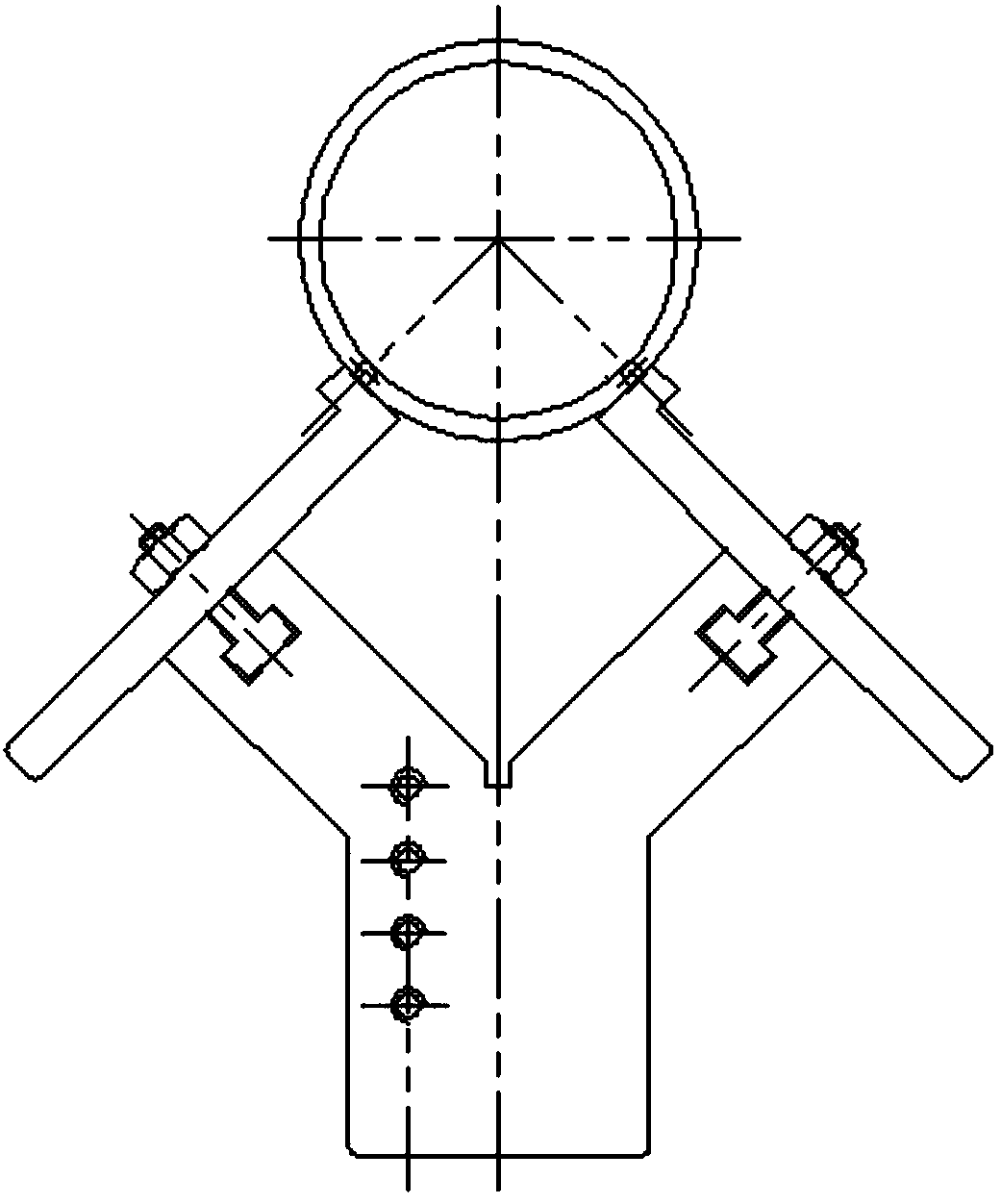

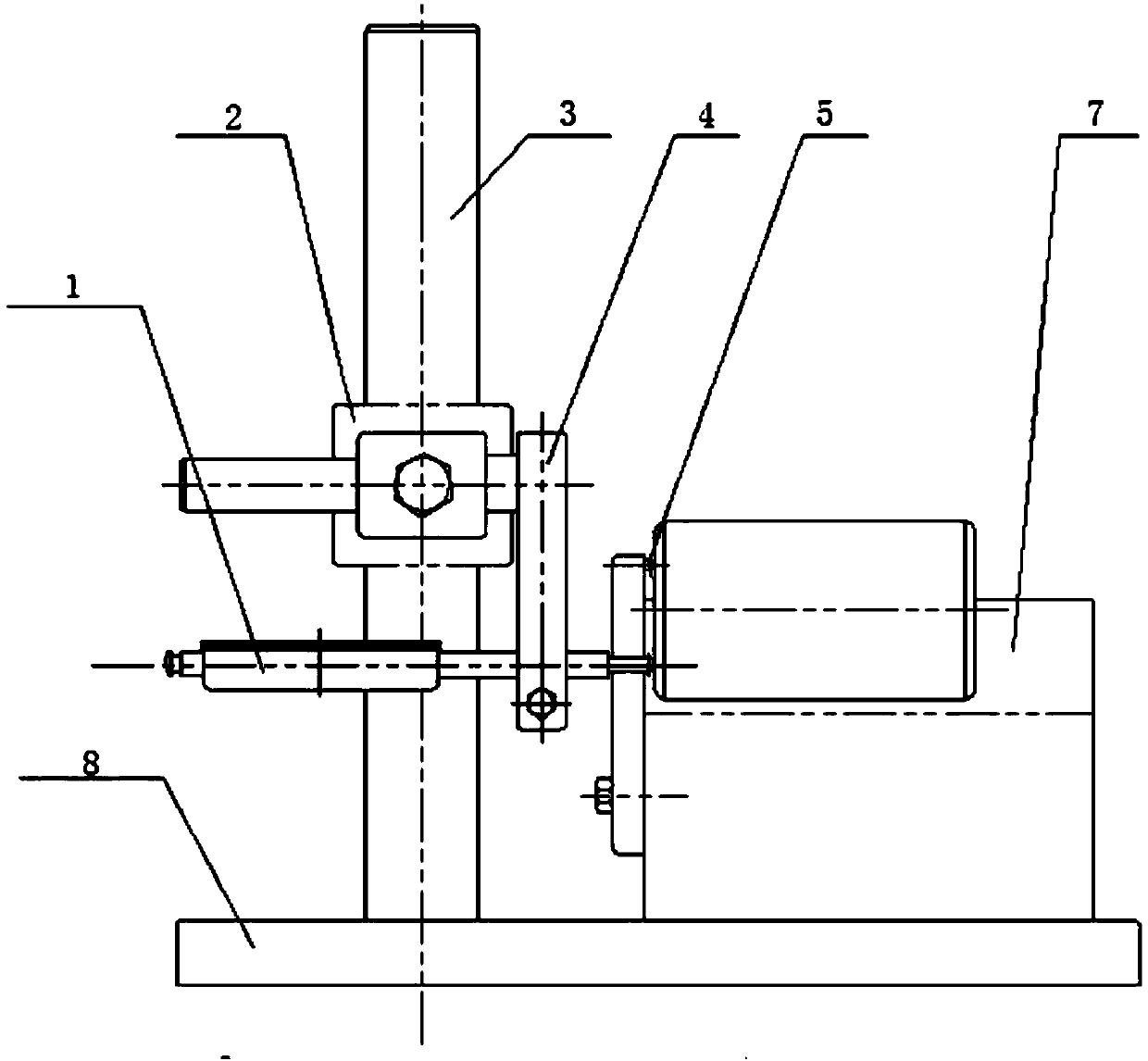

[0018] Such as Figure 5 As shown, place the cylindrical roller on the bracket 7, adjust the position of the dial indicator 1, and put the measuring head in contact with the end surface of the cylindrical roller, and the support point above the pillar 5 is in contact with the end surface of the cylindrical roller to support For the cylindrical roller, the support columns 11 and 15 on the bracket 7 need not be in contact with the outer surface of the cylindrical roller. If the roller is rotated manually, the roller rotates once, and the value measured by the dial indicator is the required value.

Embodiment 2

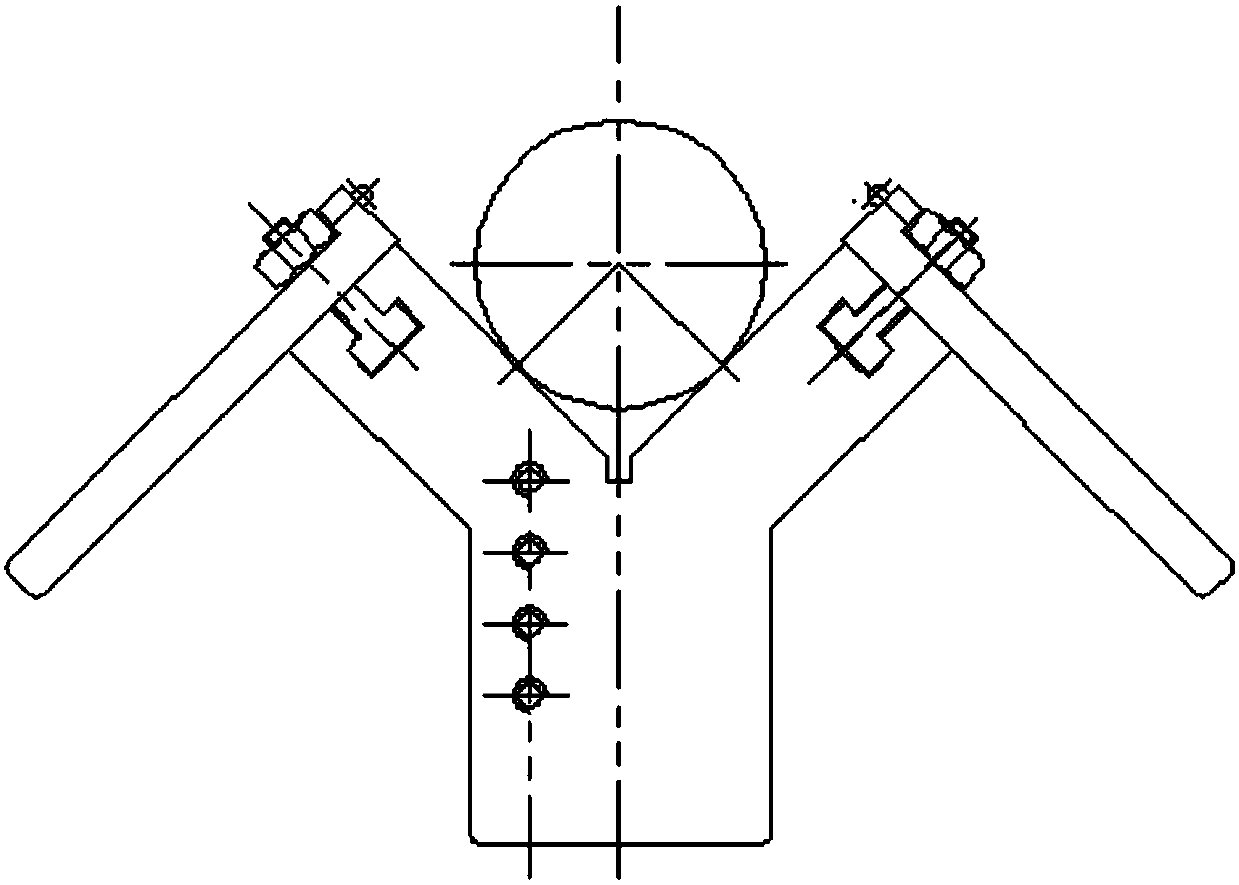

[0020] Such as Image 6 As shown, place the tapered roller on the bracket 7, adjust the position of the dial indicator 1, put the measuring head in contact with the end surface of the tapered roller, and the pillar 5 contacts the end surface of the tapered roller to support the cylindrical roller. Adjust the support columns 11, 15 on the bracket to make it contact with the outer surface of the tapered rollers, support the tapered rollers so that the axis of the tapered rollers is parallel to the base plate. Manually rotate the roller, the roller rotates once, and the value measured by the dial indicator is the required value.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com