Method for making clothes by adopting adhesive dispersing mode

A technology using point and clothing, applied in the field of clothing manufacturing, can solve the problems of high film cost, abrasion of leather clothing, poor product feel, etc., to ensure adhesion fastness and stability, guarantee adhesion fastness, The effect of excellent bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

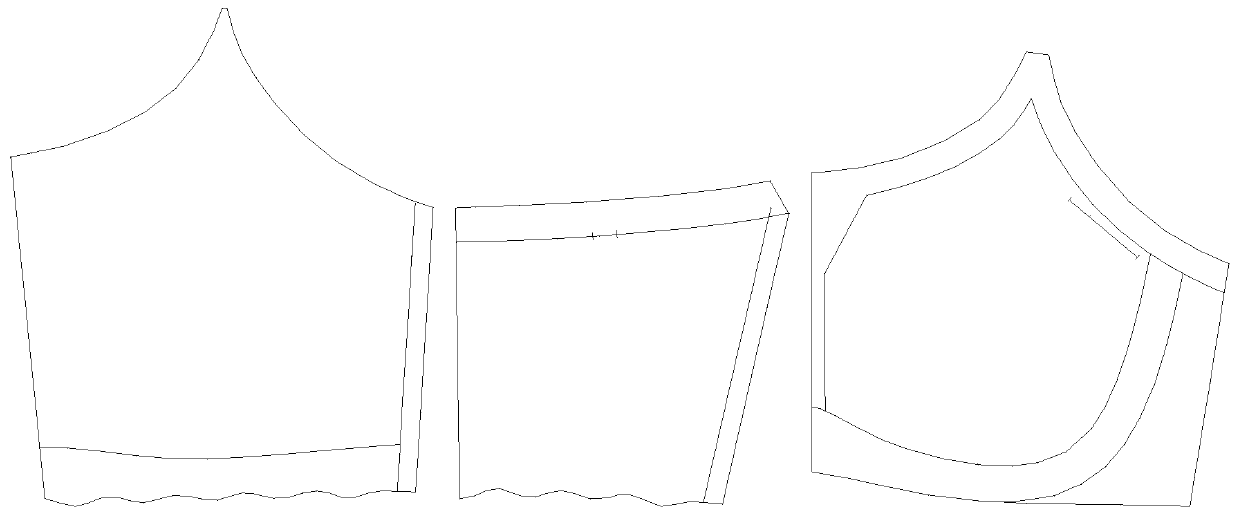

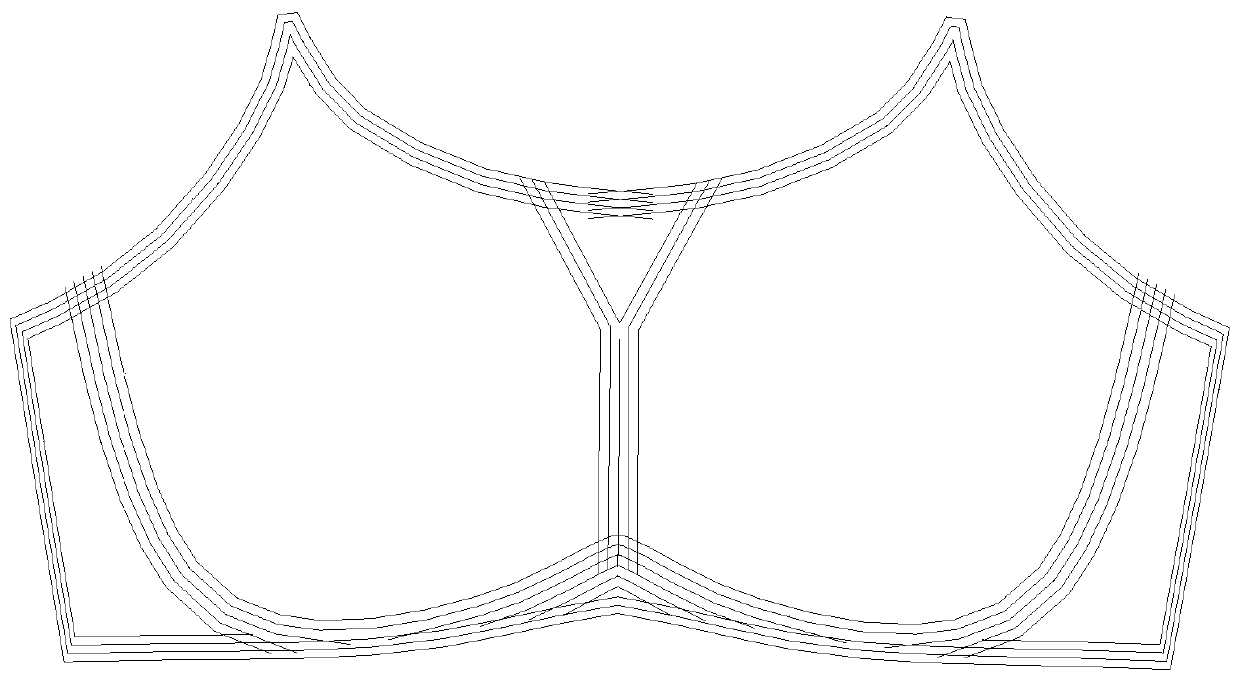

[0051] The making of embodiment one bra class style clothes

[0052] In this embodiment, the method of making clothing by dispensing adopts a specific working platform, including cutting equipment for cutting the cloth according to the set clothing style to prepare cloth pieces, and conveying equipment for transporting the cloth pieces. Device, dispensing equipment for dispensing, laminating equipment for laminating the cloth pieces after dispensing, and molding equipment for molding and fixing.

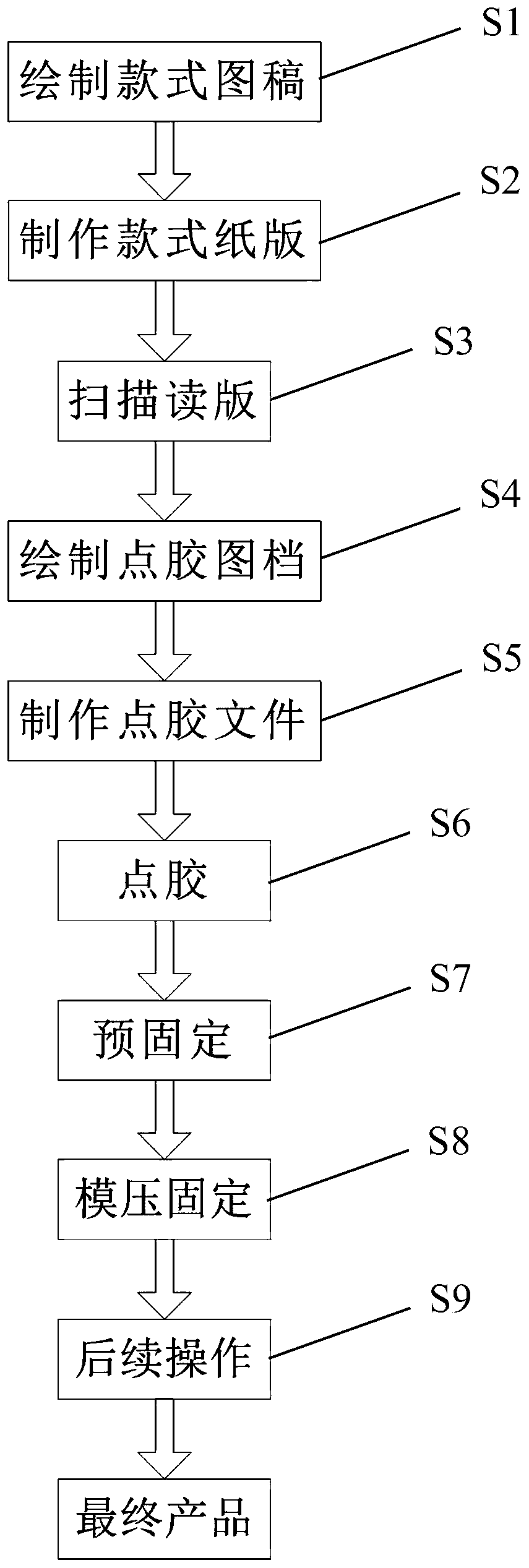

[0053] see Figure 1-6 , a kind of method that adopts the dispensing method of present embodiment to make clothes, comprises the following steps: the cutting device prepares the cloth cut piece according to the clothes style of setting, and the workbench is provided with the groove that matches with the cloth cut piece, conveying equipment The fabric cut pieces are transported to the groove of the workbench, and the dispensing equipment is installed on the workbench, and the dispens...

Embodiment 2

[0086] Embodiment 2 The making of home clothes style clothing

[0087] refer to Figure 7-13 , the method of making clothes by dispensing in this embodiment is basically the same as the making process in the first embodiment. From step S1 to step S5 of example 1, the pattern drawing on the initial style is different from the parameters of the final dispensing operation, such as dispensing starting point, dispensing track, etc., and the steps in embodiment 1 can be omitted S7 and step S9.

Embodiment 3

[0088] The making of embodiment three trousers style clothes

[0089] refer to Figure 14-18 , the method of making garments by dispensing in this embodiment is basically the same as the manufacturing process in Embodiment 1, the difference is that what is made in this embodiment is the pants style clothing, the manufacturing process and process are generally similar, only in the implementation From step S1 to step S5 of example 1, the pattern drawing on the initial style is different from the parameters of the final dispensing operation, such as dispensing starting point, dispensing track, etc., and the steps in embodiment 1 can be omitted S7 and step S9.

[0090] This embodiment adopts the bra style clothing product that adopts the method for making clothing by dispensing, has the following many advantages: adopts traceless super-elastic fabric, the whole pair of trousers does not have any sewing stitches, comfortable and traceless; It adopts pure cotton cloth for glue dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap