A cargo transfer robot

A robot and cargo technology, which is applied in the field of cargo transfer robots, can solve the problems that heavy cargo cannot be loaded and unloaded directly, and achieve the effects of not being easily deformed, ensuring safety, and ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below with reference to the accompanying drawings, by describing the embodiments, the specific embodiments of the present invention are described in further detail, to help those skilled in the art have a more complete, accurate and deep understanding of the inventive concept and technical solutions of the present invention.

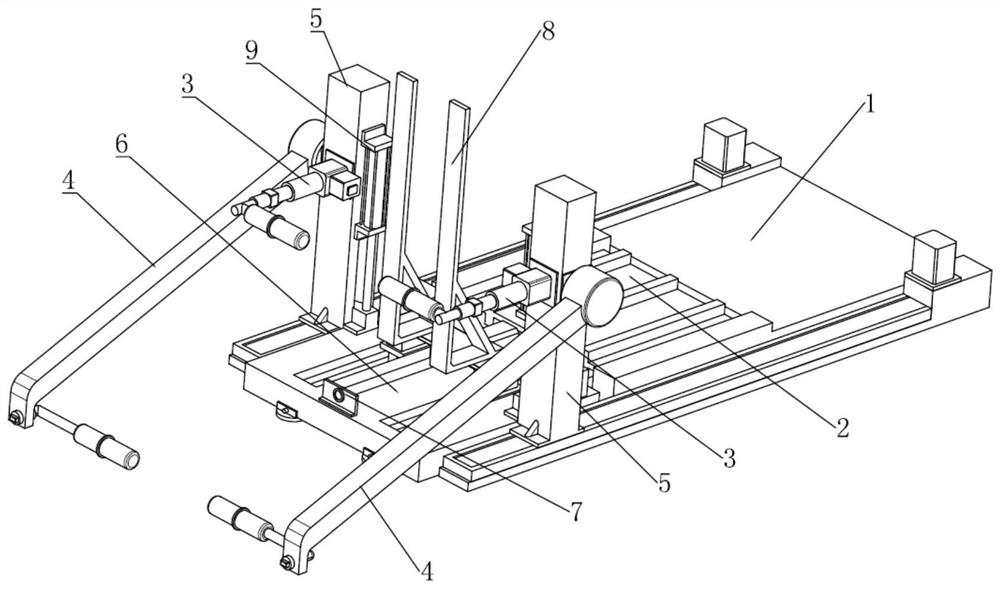

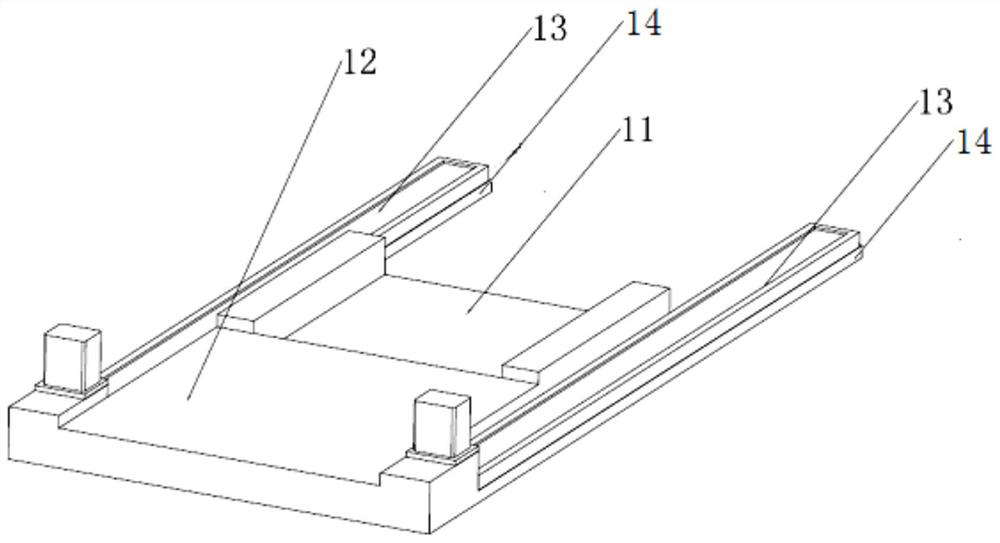

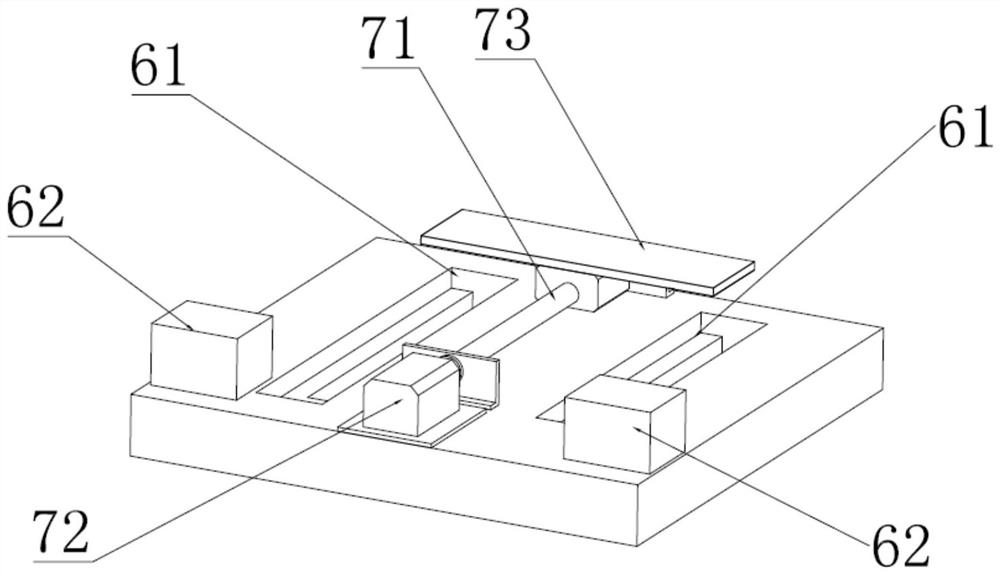

[0034] Such as Figure 1-12As shown, the present invention provides a robot for cargo transfer, a robot for cargo transfer, comprising a car body 1 and a walking mechanism arranged in the car body 1, characterized in that: the front part of the car body 1 is provided with There is a backing board receiving groove 11 for a built-in transportation backing board 2, a platform receiving groove 12 is provided at the rear of the car body 1, and linear modules 13 arranged in the front and rear direction are symmetrically arranged on both sides of the car body 1 top, and the straight line module 13 Columns 5 are installed on the slide table of the module ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com