Laying forming mold for resin-matrix composite battery case of new-energy automobile

A technology for new energy vehicles and composite materials, which is applied in the field of resin matrix composite material battery box placement molding molds for new energy vehicles, and composite material placement molding mold fields, which can solve the problem that dimensional accuracy and structural accuracy are difficult to guarantee, and there is a lack of mold design references. , the problem of demolding difficulty, etc., to achieve the effect of stable overall structure of the mold, not easy to deform the overall structure of the mold, and overcome the difficulty of demoulding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific implementation manners of the present invention will be further described below in conjunction with the technical solutions and accompanying drawings.

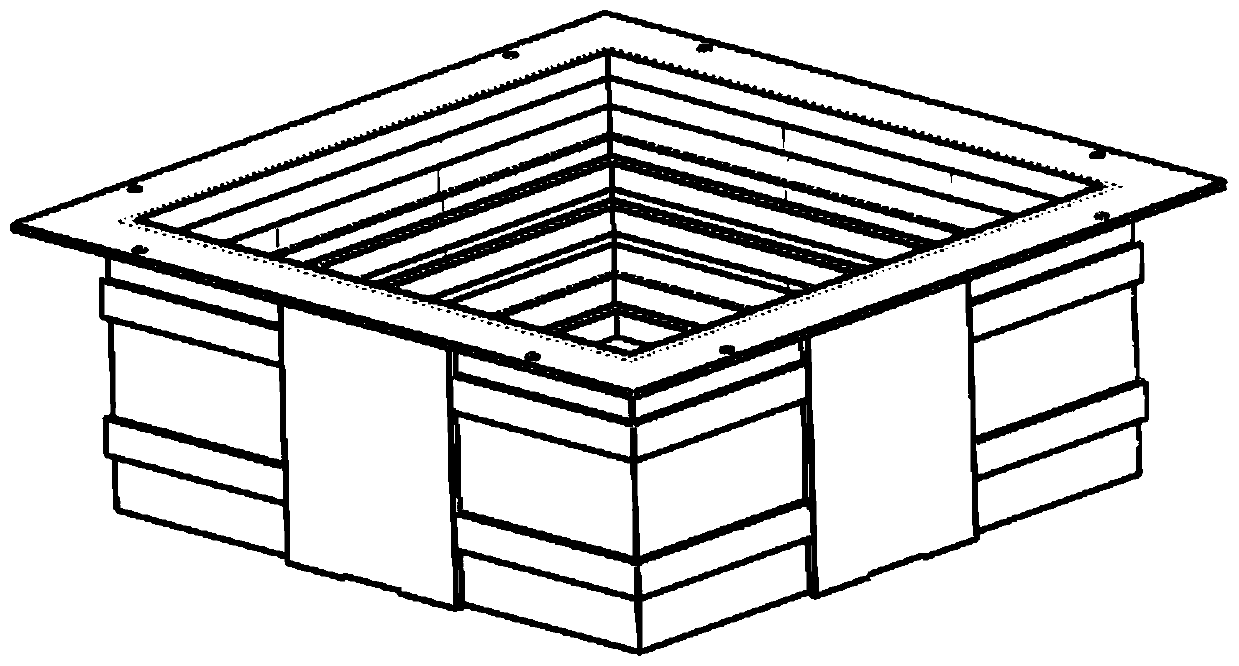

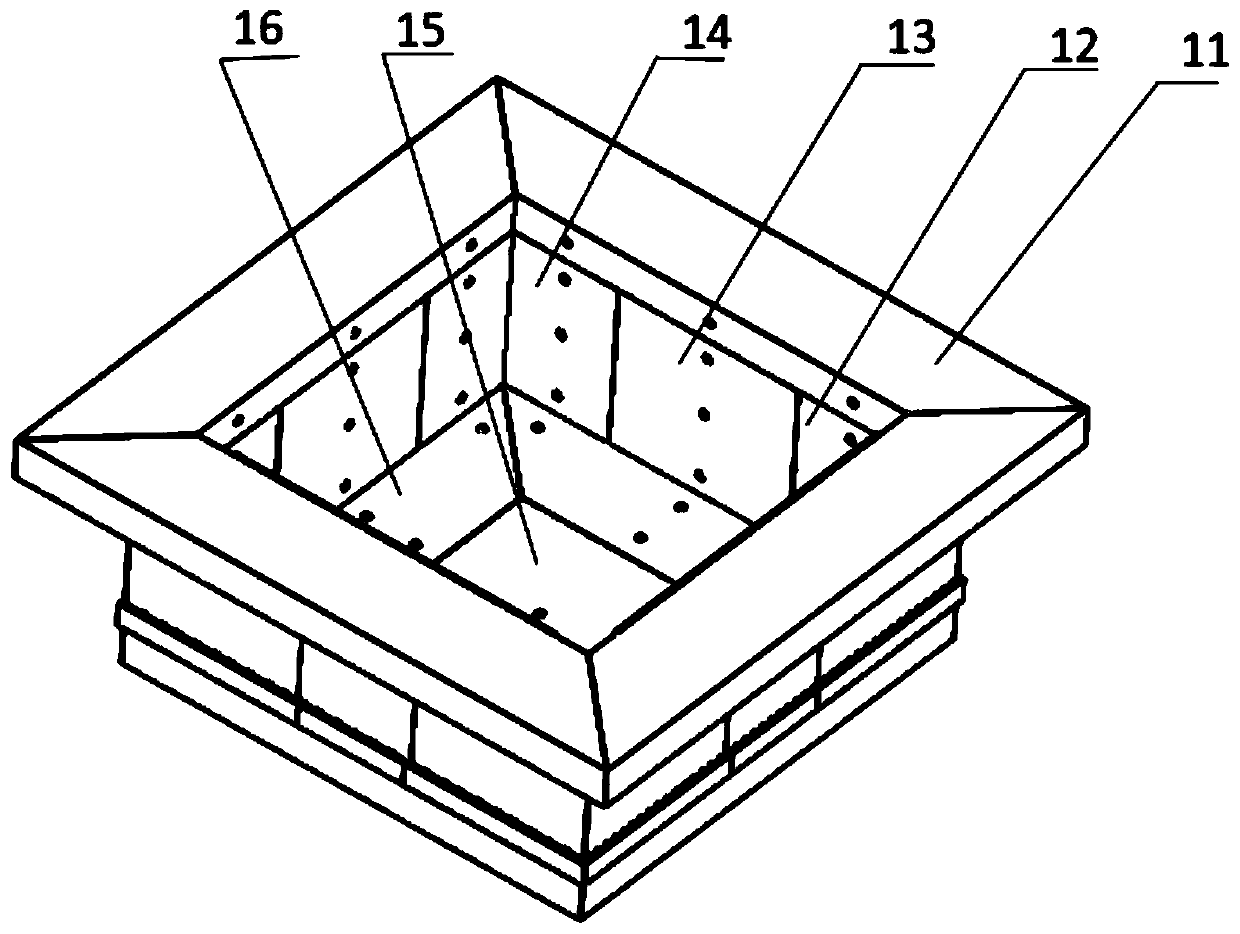

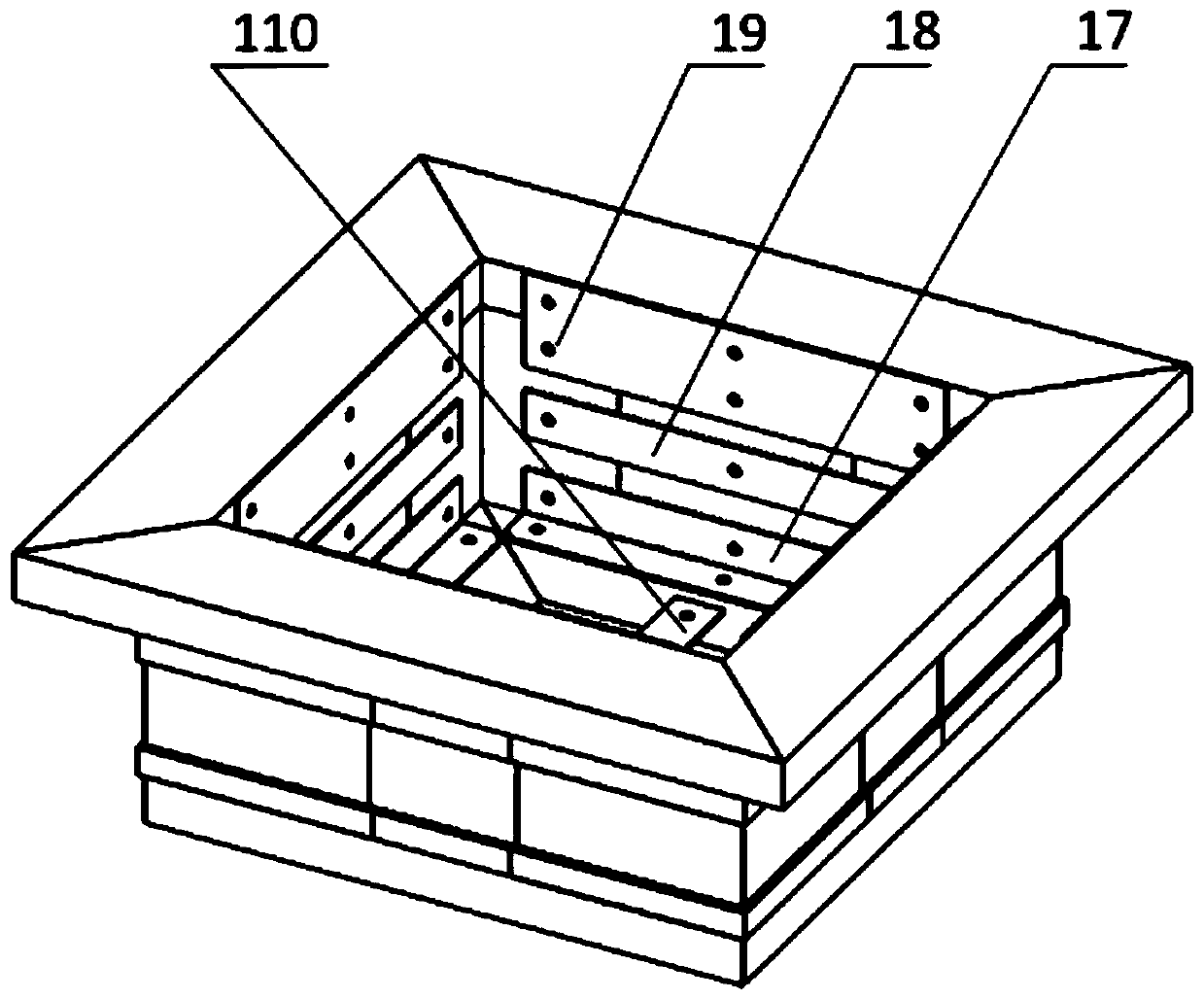

[0034] Such as image 3 , Figure 5 and Figure 6 As shown, a resin-based composite molding mold for new energy vehicles includes an inner mold, an outer mold and a fastening device;

[0035] The inner mold includes inner flanging x 4, inner side panel-front x 4, inner side panel-middle x 4, inner side panel-back x 4, inner bottom four corners and inner bottom center x 1. Each part is provided with threaded holes so as to be connected as a whole through the cross-shaped connecting piece 110, the right-angled connecting piece 17, the inner plate connecting piece 18 and the inner plate-flange connecting piece 19;

[0036] When the inner mold is working, all parts of the inner mold should be combined into a whole. The combination sequence is as follows: 1. Connect the middle 15 of the inner bottom surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com