Rough processing and ultrasonic assisting fine processing type forming machine tool for composite grinding wheel and control method

An ultrasonic-assisted, grinding wheel technology, applied in metal processing equipment, grinding machine parts, grinding automatic control devices, etc., can solve the problems of tool wear and low processing efficiency, and achieve dimensional accuracy and geometric accuracy with high efficiency , good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

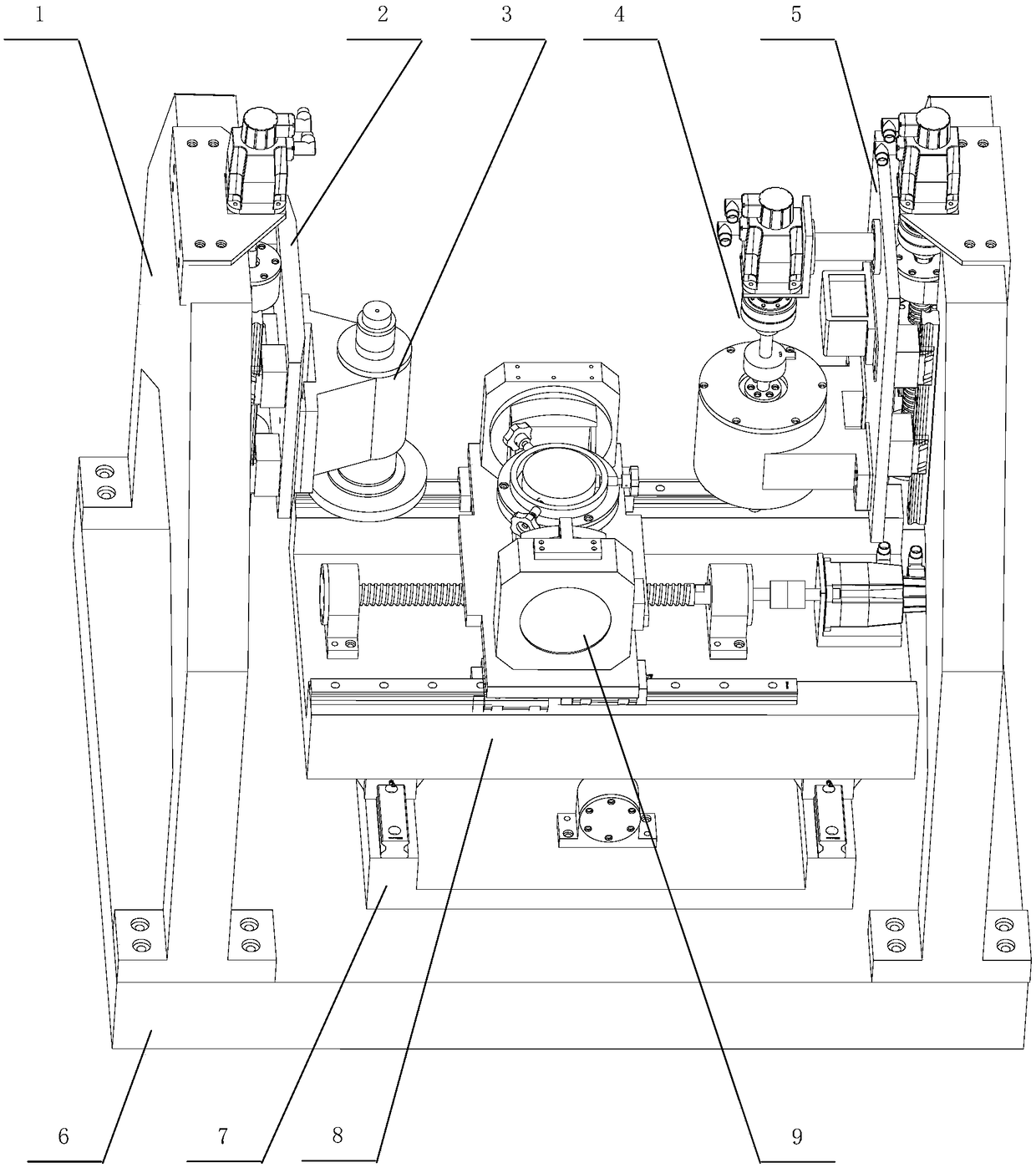

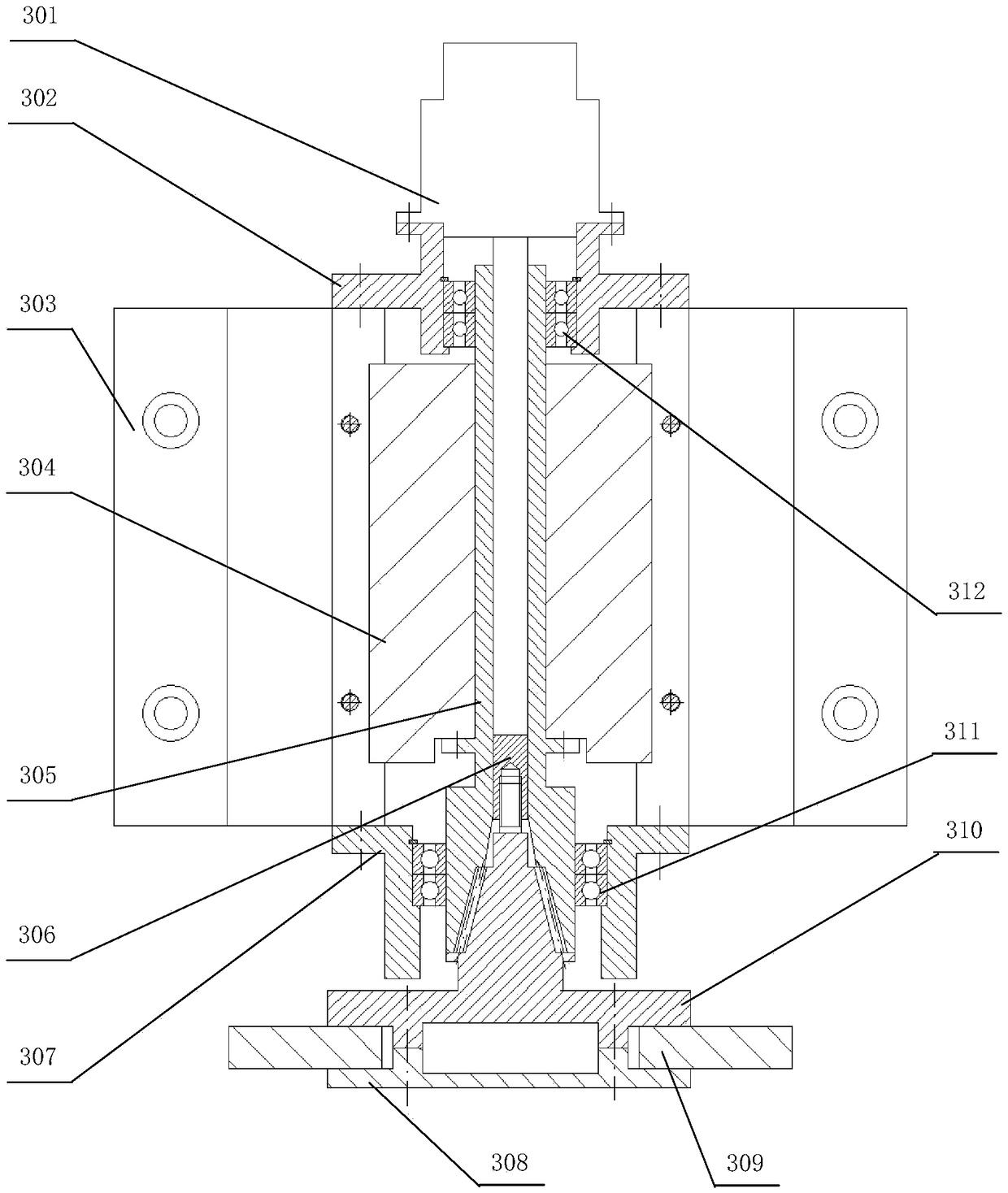

[0035] Such as figure 1As shown, it includes gantry 1, Z guide rail 1 2, grinding wheel grinding tool 3, ultrasonic tool system 4, Z guide guide 2 5, base 6, Y guide rail 7, X guide rail 8, rotating and swinging double-axis turntable 9, Wherein the two gantry 1 are respectively fixedly connected on the left and right sides of the base 6 by bolts, the Y guide rail 7 is longitudinally fixedly connected to the middle position above the base 6 by bolts, and the X guide rail 8 is fixed and installed on the Y guide rail 7 laterally by bolts. On the sliding plate, the rotating and swinging double-axis turntable 9 is longitudinally fixed on the sliding plate of the X guide rail 8 through bolts, and the Z guide rail 1 is fixedly connected to the middle position on the right side of the left gantry 1 through bolts, and the grinding tool 3 passes through the Bolts are fixedly connected to the sliding plate of the Z guide rail 1 2, the Z guide rail 2 5 is fixedly connected to the middle p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com