Chair forward and backward sliding mechanism driven by motor and stay rope

A technology of sliding mechanism and driving mechanism, applied in movable seats, vehicle seats, transportation and packaging, etc., can solve problems such as unsatisfactory, achieve simple and practical structure, meet changing requirements, and increase the effect of moving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

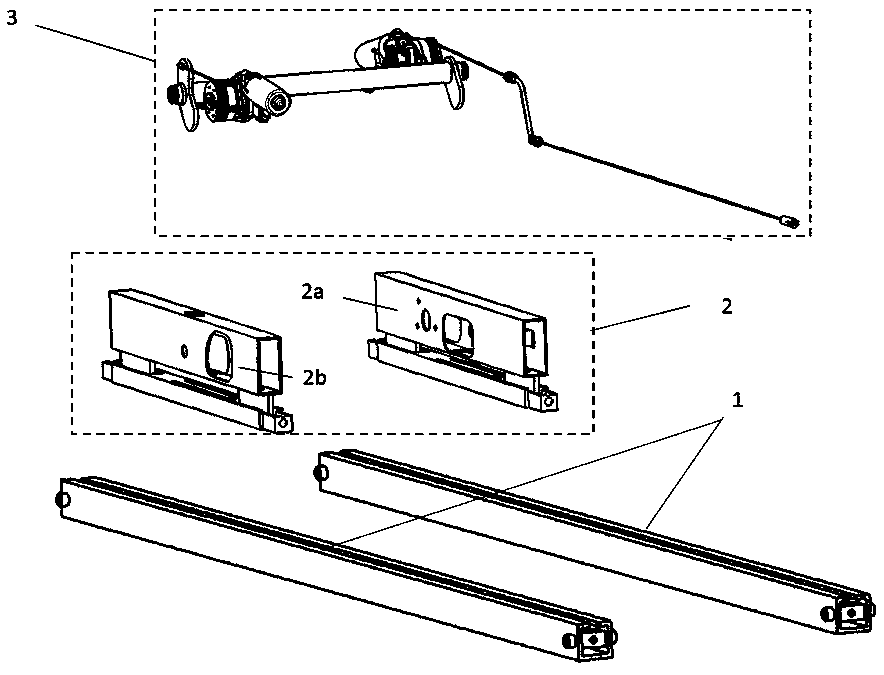

[0025] Such as figure 1 As shown, a front and rear sliding mechanism of a seat driven by a motor and a cable includes: a slide rail 1 , an upper bracket assembly 2 , and a driving mechanism 3 .

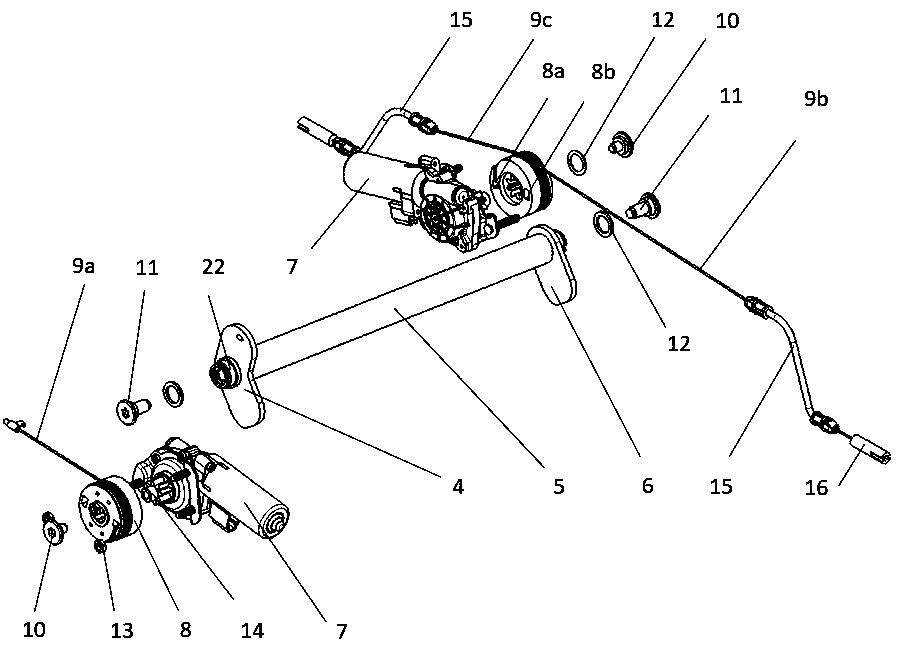

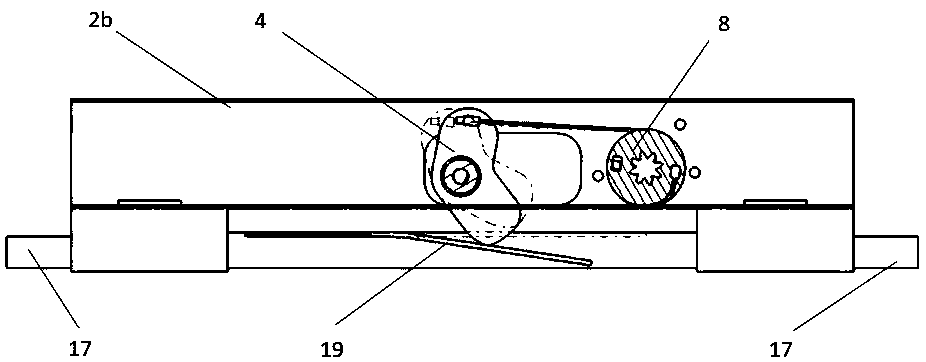

[0026] Such as figure 2 As shown, the drive mechanism 3 is composed of a rotating shaft assembly, an unlocking device, a wire pulling device, and a winding drum 8 . The shaft assembly is mainly composed of a pull plate 4, a press plate 6, and a round tube 5. The pulling plate 4 is coaxial with the pressing plate 6 and has the same rotation radius, and is fixedly connected to both ends of the round tube 5 respectively. After the two ends of the round tube 5 of the rotating shaft assembly are penetrated from the inner side of the upper bracket assembly 2 respectively, the fixed connection with the upper bracket assembly 2 is realized through welding nuts 22 , washe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com