Interior cladding arrangement for a load space

A cladding and load-carrying technology, which is applied to vehicle components, superstructures, superstructure subassemblies, etc., can solve problems such as a large number of installation steps, increased error rates and costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In different figures, the same parts always have the same reference signs, so these parts are usually only described once. If a single component, element or group of components is mentioned in the singular, this also includes the plural.

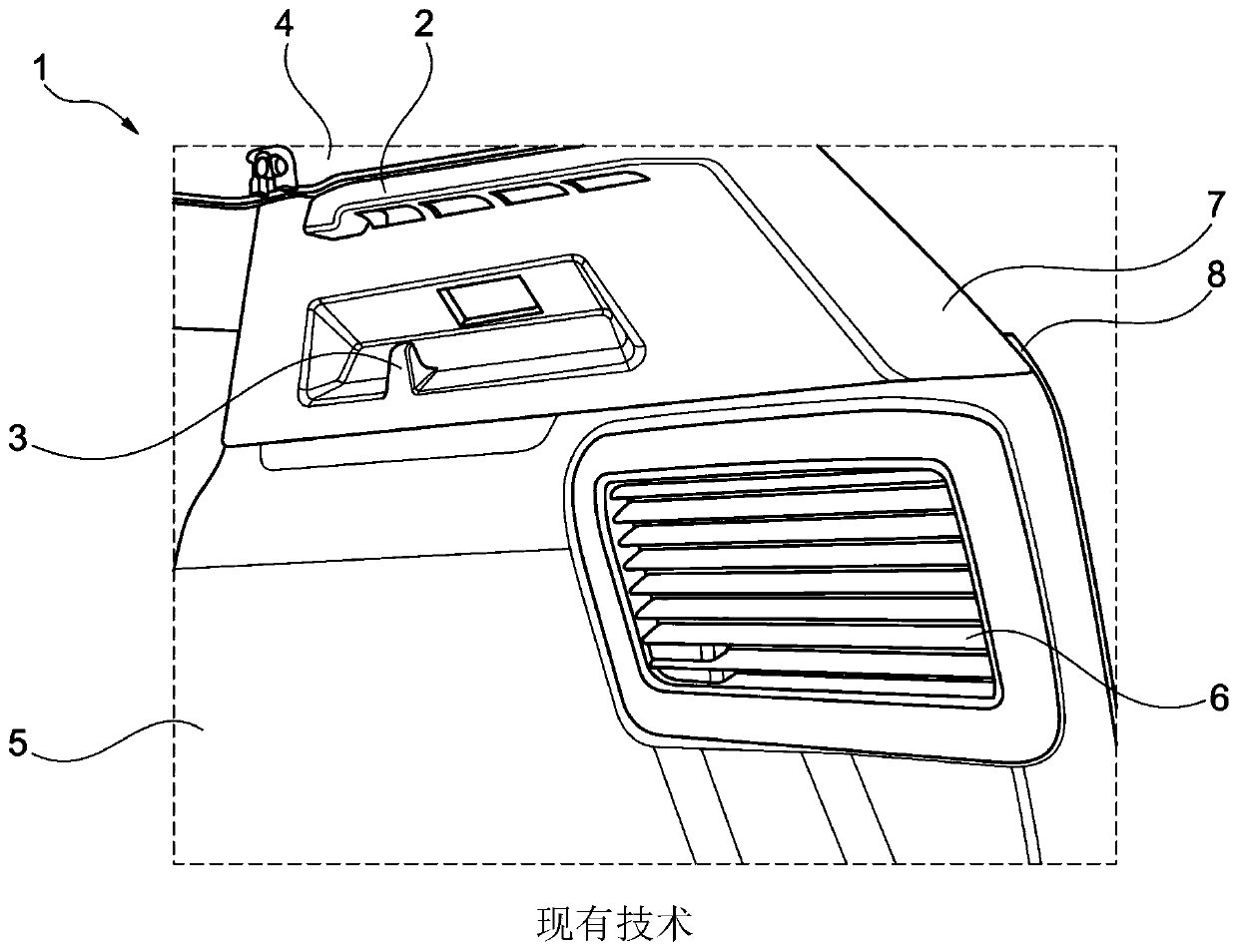

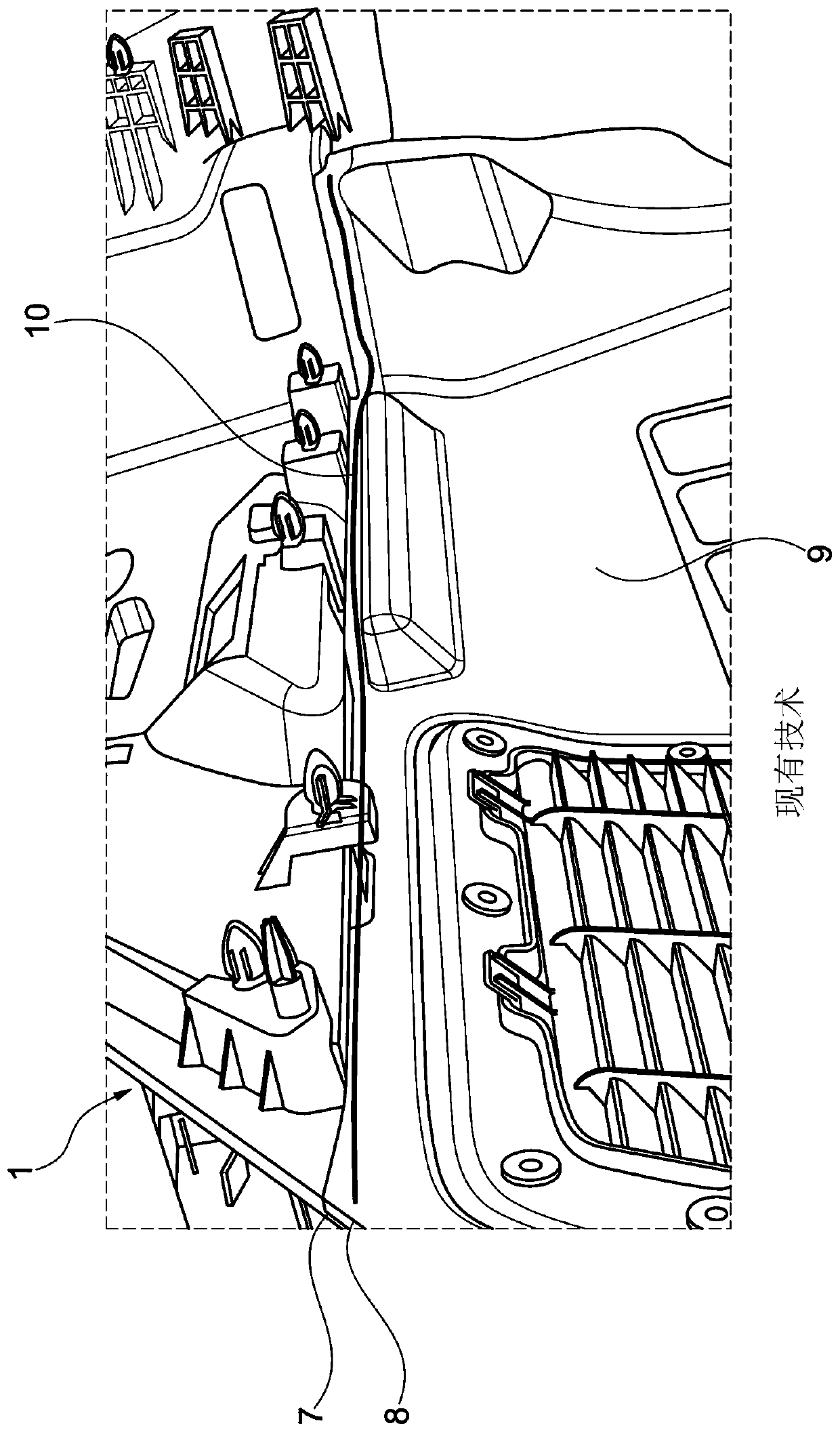

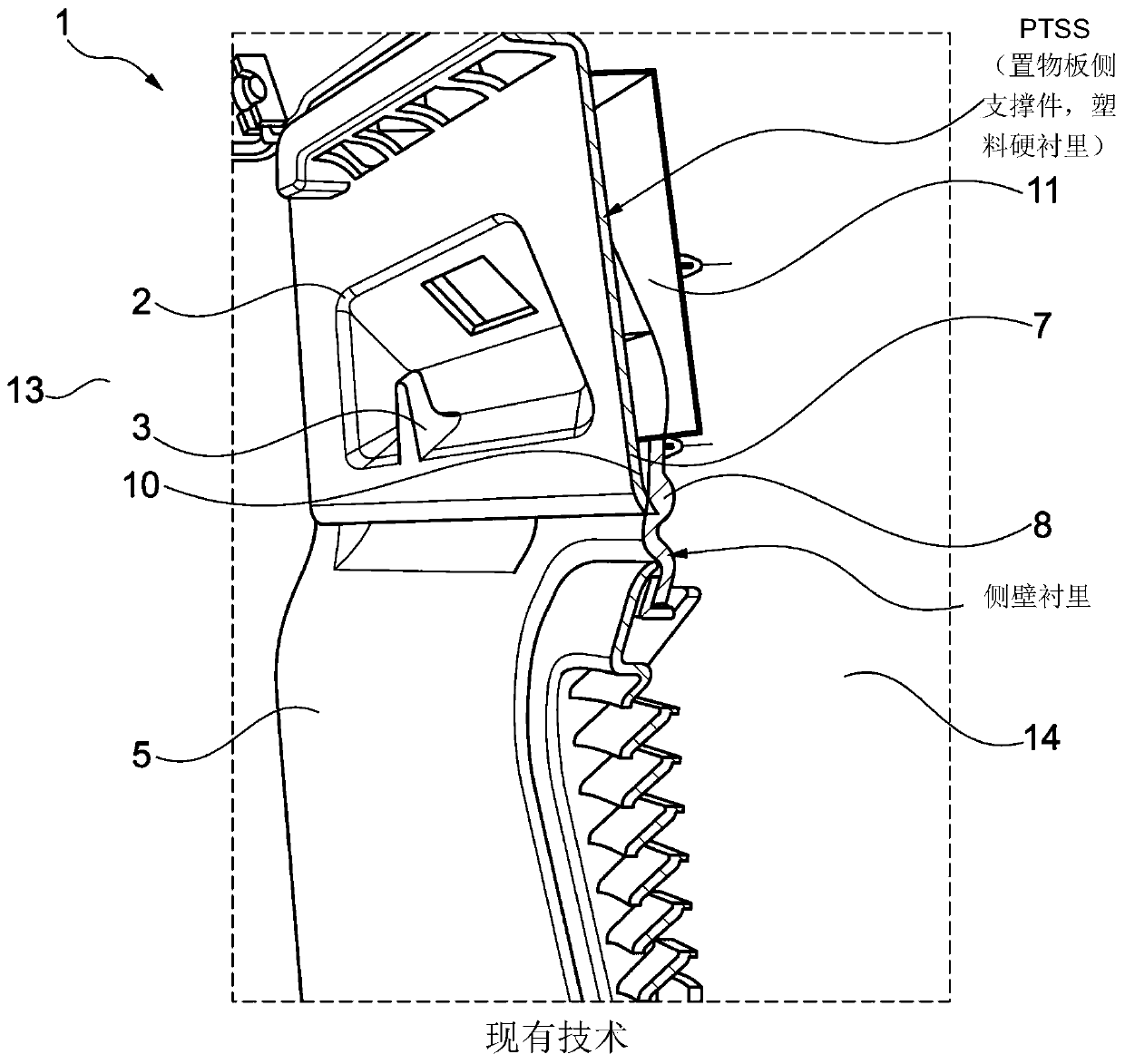

[0031] figure 1 An arrangement known in the prior art for inner cladding, ie inner cladding arrangement 1 , is shown. The illustrated interior cladding arrangement 1 shows a support wall 2 with cover plate attachment means 3 . The cover attachment device 3 is designed here as an upwardly protruding hook element into which a cover or a coat rack delimiting the load space of the motor vehicle at the upper side can be hung or inserted for support. Furthermore, the interior cladding arrangement 1 is connected to a vehicle body 4 . The support wall 2 is usually designed as a support element with an injection-molded hard shell part. A cover wall 5 is arranged next to or adjacent to it, which basically mainly fulfills a decorative and / or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com