Throttling stop wear-resistant gate valve

A technology of gate valves and gates, which is applied in the direction of sliding valves, valve details, valve devices, etc., can solve the problems of scouring and wear of sealing ports, tight closing of stop valves, and no cut-off function of throttle valves, etc., to achieve overall wear resistance Improved performance and lower operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

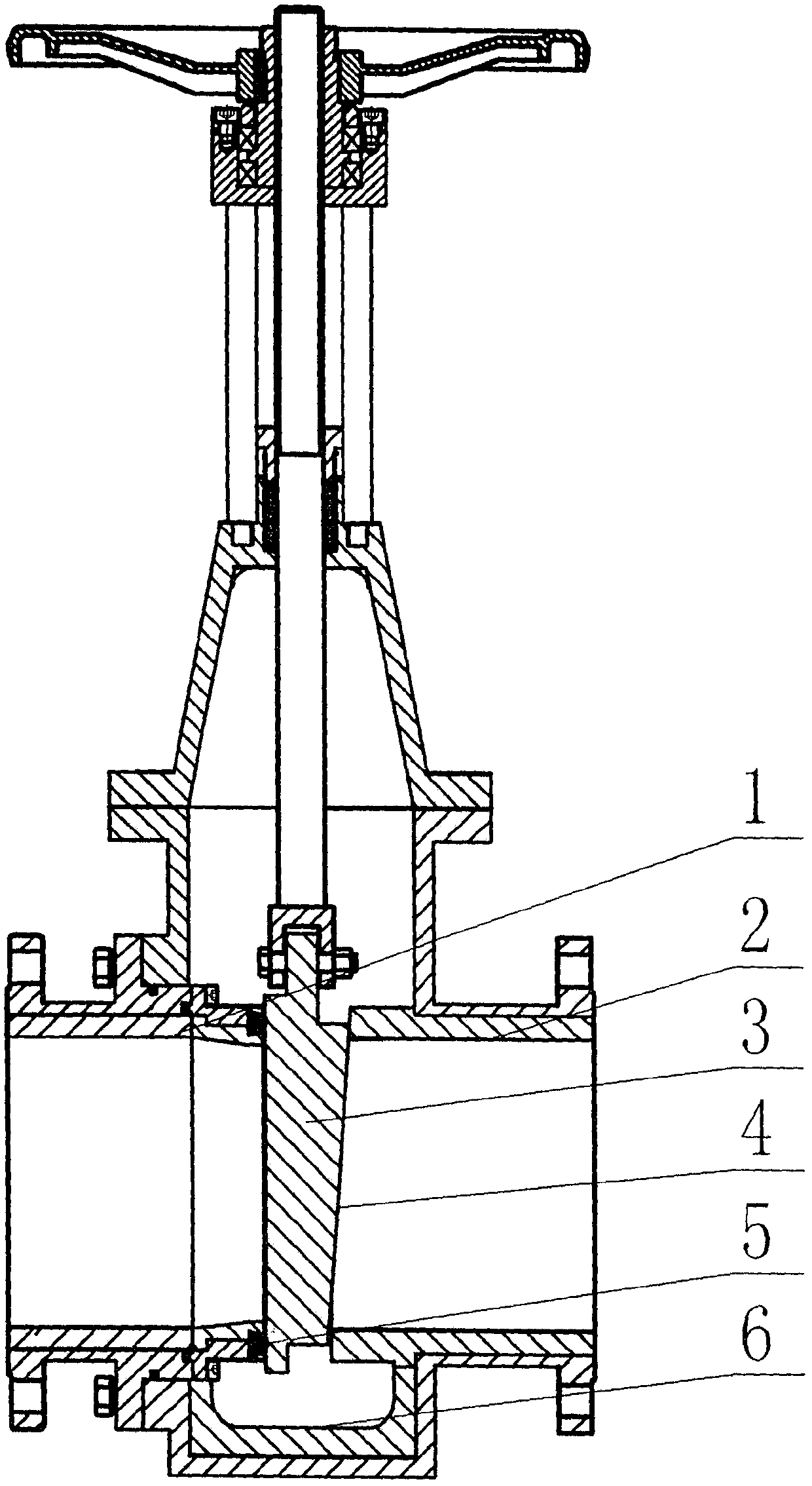

[0014] The specific embodiment 1, accompanying drawing has provided a kind of specific structure of the present invention, refer to figure 1 , a throttling cut-off wear-resistant gate valve, the valve body has an inflow short pipe (1) and an outflow short pipe (2), with a gate (3) and a gate lifting opening and closing mechanism, and the gate (3) is connected to the outflow The contact surface of the inner end surface of the short pipe (2) is a wedge-shaped ram surface (4), the ram (3) is a wear-resistant ram, and the inner walls of the inflow short pipe (1) and the outflow short pipe (2) are wear-resistant layers. The inner end of the inflow stub has a seal (5). The bottoms of the inflow short pipe (1) and the outflow short pipe (2) are provided with diversion grooves (5), and the inner wall of the material guide groove (6) has a wear-resistant layer. Diversion channels reduce bottom sediment. In the throttling cut-off wear-resistant gate valve provided by the invention, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com