Extension pipe type perforated plate honeycomb sandwich sound absorption structure

A technology of honeycomb interlayer and perforated plate, which is applied in the direction of jet propulsion devices, gas turbine devices, machines/engines, etc., can solve problems such as difficult to achieve effective absorption of lower frequency noise, and achieve excellent sound absorption effect, easy design, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

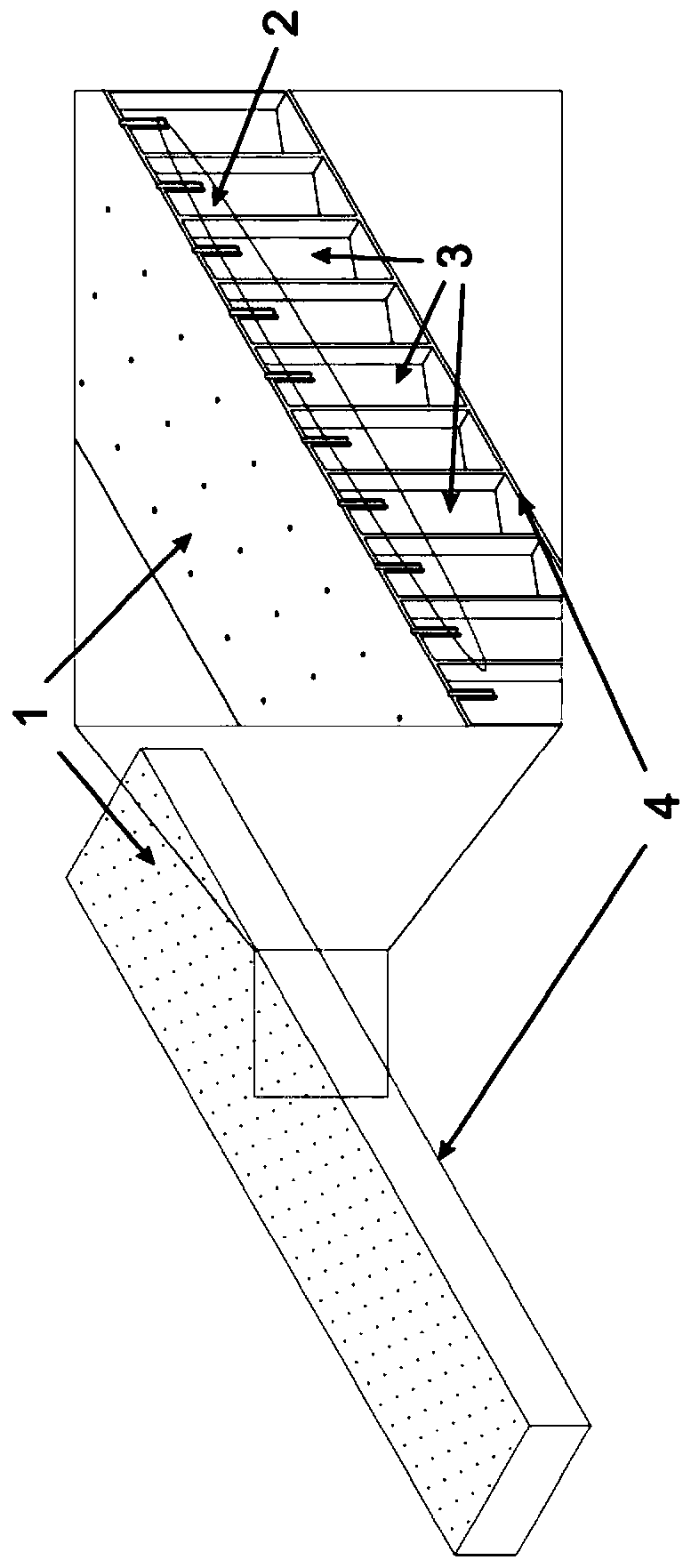

[0028] Such as figure 1 As shown, an extended tubular perforated plate honeycomb sandwich sound-absorbing structure includes the following parts:

[0029] a plate-shaped perforated plate 1 with several micropores evenly distributed;

[0030] flat back plate 4;

[0031] The honeycomb base between the perforated plate 1 and the back plate 4.

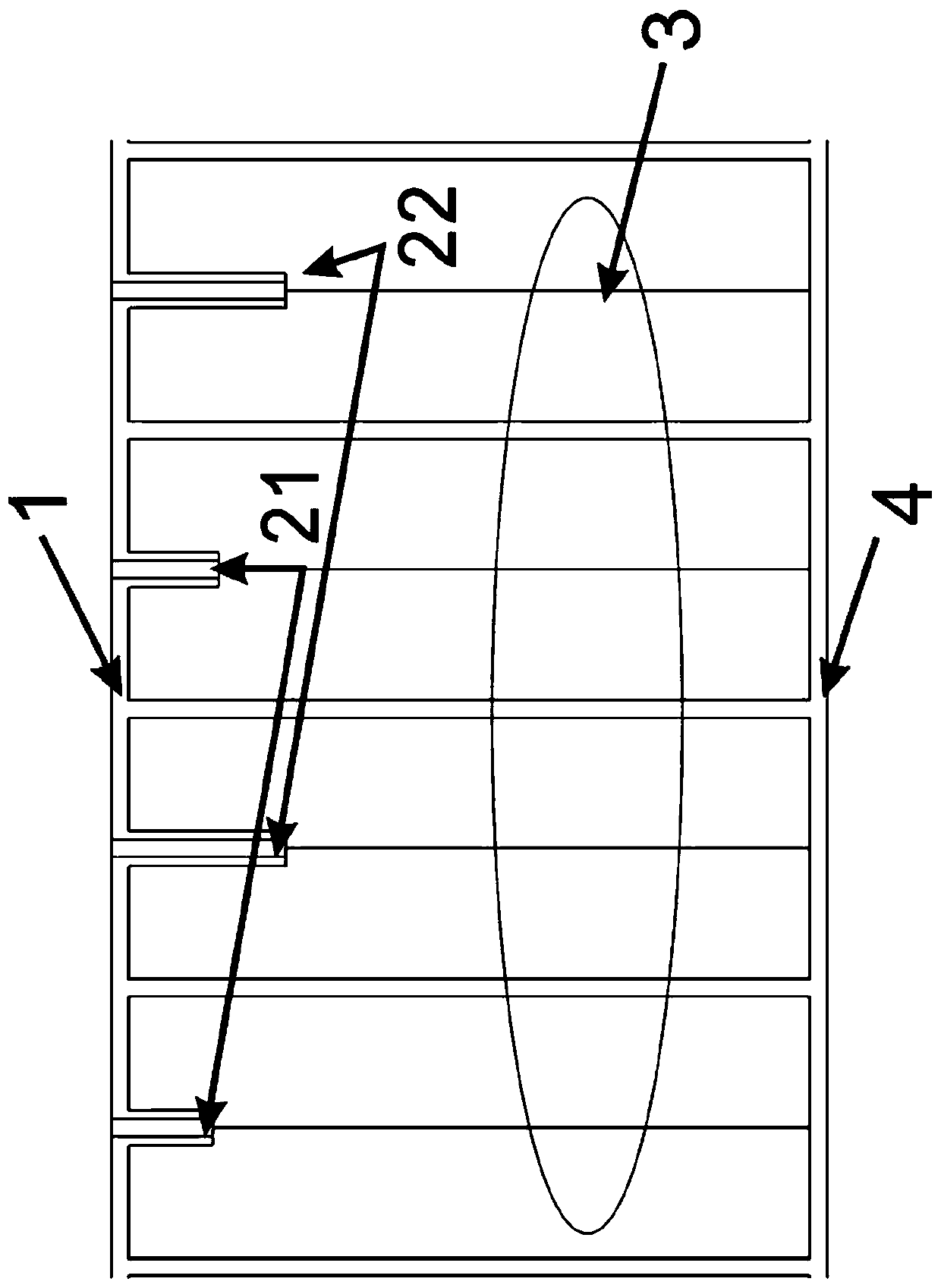

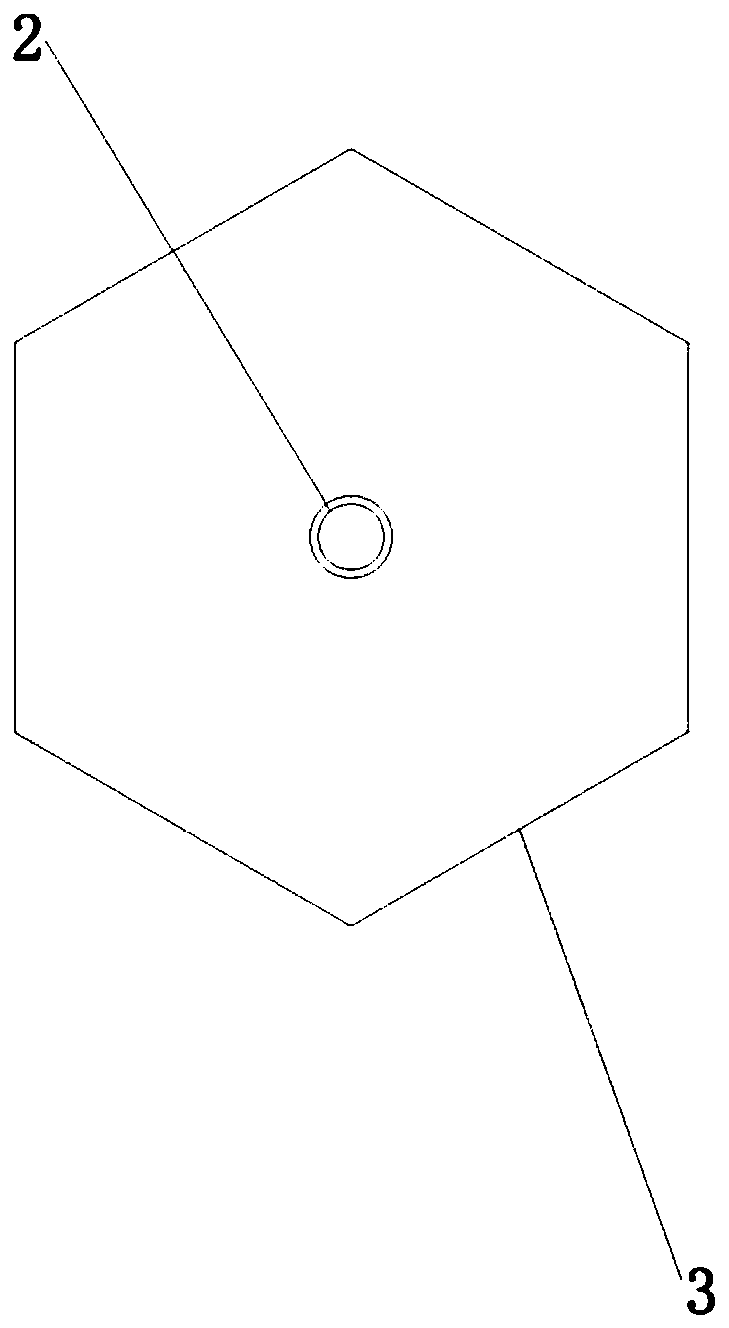

[0032] Among them, the perforated plate 1, the honeycomb base, and the back plate 4 are fixedly connected sequentially from top to bottom. Parallel to each other, the honeycomb seat has several honeycomb cavities 3, the shape of the honeycomb cavity 3 is a regular hexagonal prism, and the overall length direction of the honeycomb cavity 3 is perpendicular to the perforated plate 1 and the back plate 4, and each honeycomb cavity 3 corresponds to a thin hollow The extension tube 2 in the shape of a round tube, the upper end of each extension tube 2 is fixedly connected to the lower surface of the perforated plate 1 and communicated with o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com