A vacuum buffer tank

A technology for vacuum buffer tanks and tanks, which is applied in the field of buffer tanks, and can solve the problems that liquid-phase substances are easy to gather at the bottom of the tank and affect the vacuum degree of the buffer tank, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

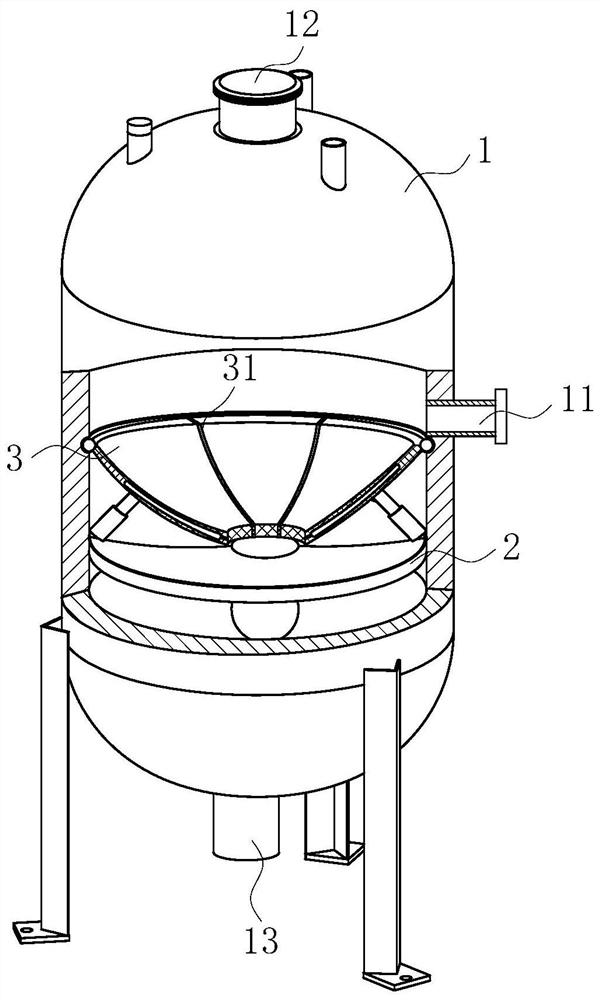

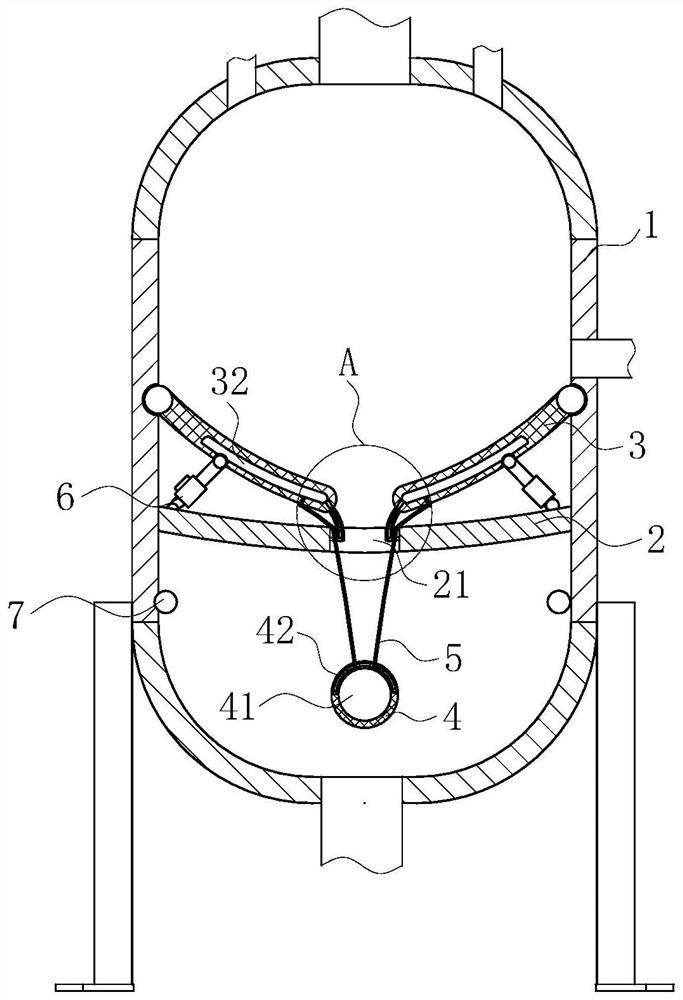

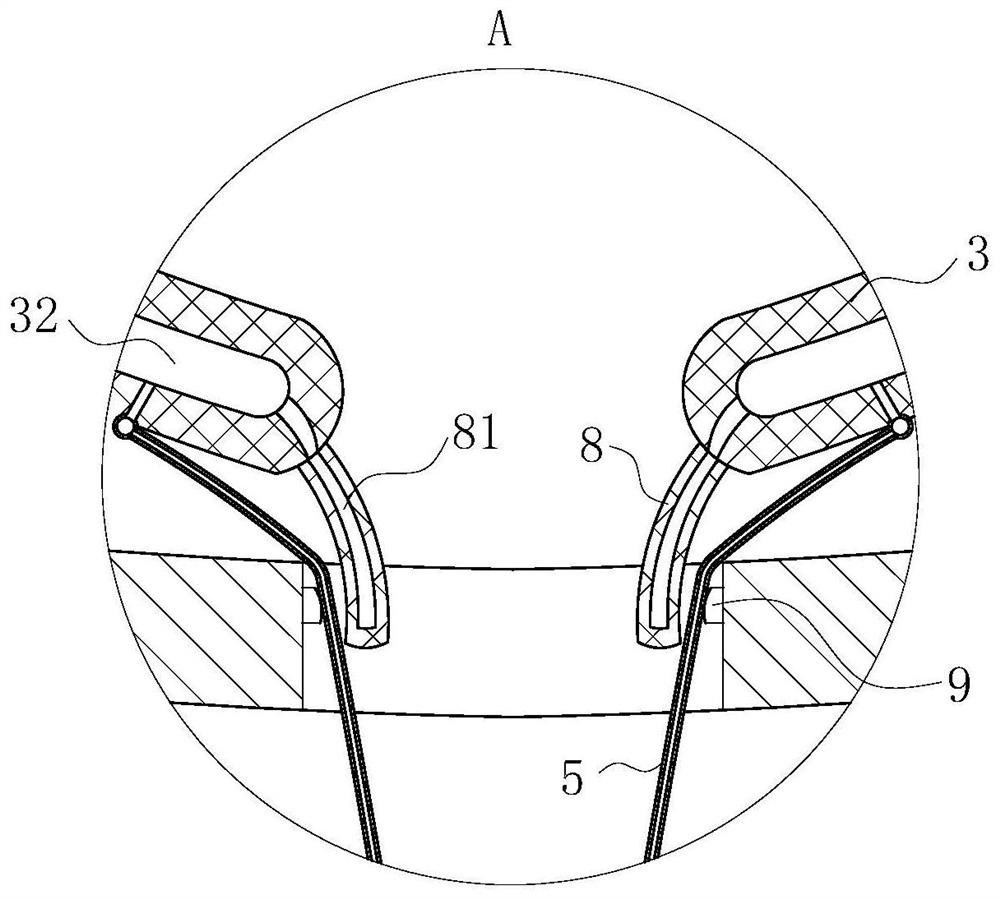

[0020] use Figure 1-Figure 4 A vacuum buffer tank according to one embodiment of the present invention will be described as follows.

[0021] Such as Figure 1-Figure 4As shown, a vacuum buffer tank according to the present invention includes a tank body 1; an air inlet 11 is provided on the side wall of the tank body 1, and an air outlet 12 is provided at the top of the tank body 1, and the tank body The bottom end of 1 is provided with a drain port 13; the tank body 1 is equipped with a diversion recessed plate 2, and the diversion recessed plate 2 is provided with a diversion hole 21; the upper part of the diversion recessed plate 2 is installed obliquely There are a plurality of fan-shaped deflectors 3, and the plurality of fan-shaped deflectors 3 are hinged on the inner wall of the tank body 1 through hinge columns, and the fan-shaped deflectors 3 are located below the air inlet 11; each fan-shaped deflector 3 They are all connected by elastic membranes 31, and the end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com