Open-loop lithium bromide heat pump system

A heat pump system, ring lithium bromide technology, applied in the direction of refrigeration and liquefaction, climate change adaptation, energy-saving heating/cooling, etc., can solve the problem of not being able to make full use of the generation chamber, and achieve the effect of reducing the amount of cooling circulating water and reducing the discharge of waste heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

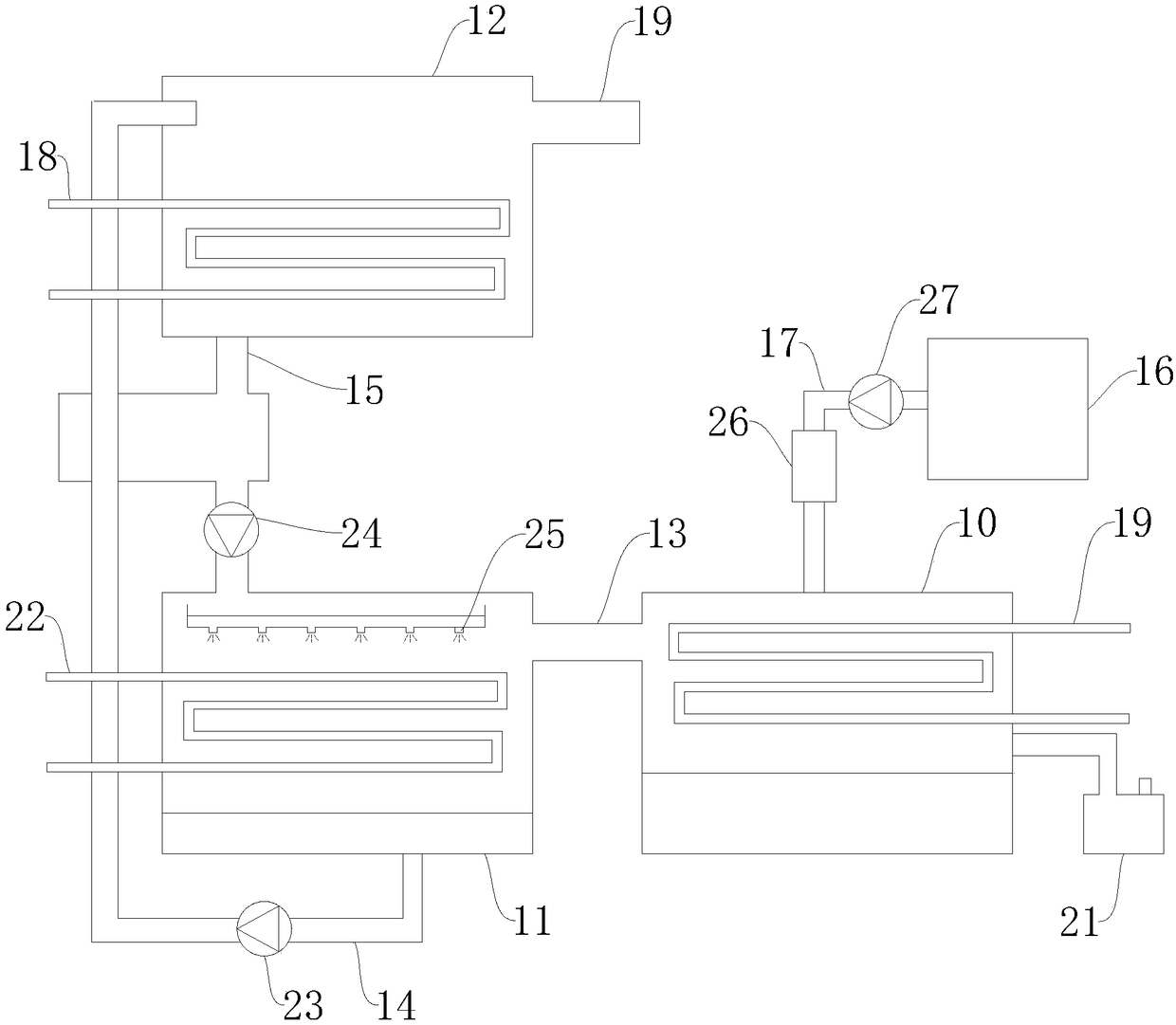

[0021] An open-loop lithium bromide heat pump system, such as figure 1 As shown, it includes an evaporation chamber 10, an absorption chamber 11 and a generation chamber 12. The evaporation chamber 10 transports the steam in the absorption chamber 11 through the first pipeline 13, and the absorption chamber 11 transmits the diluted lithium bromide in it through the second pipeline 14. In the generation chamber 12, the generation chamber 12 transports the concentrated lithium bromide in it to the absorption chamber 11 through the third pipeline 15; it also includes a refrigerant water tank 16, and the refrigerant water tank 16 communicates with the evaporation chamber 10 through the fourth pipeline 17. The vacuum degassing tank 26 that is used to slough the air in water is installed on the four pipelines 17. A vacuum degassing tank 26 is set at the replenishment port of the refrigerant water to extract the air dissolved in the water to prevent oxygen from being brought into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com