A measurement and design system and design method for the furnace wall insulation structure of a waste incineration boiler

A boiler furnace wall and waste incineration technology, applied in the direction of combustion method, radiation pyrometry, incinerator, etc., can solve the problems of single insulation material and unreasonable design of multi-layer insulation structure, and achieve structural design and multiple functions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

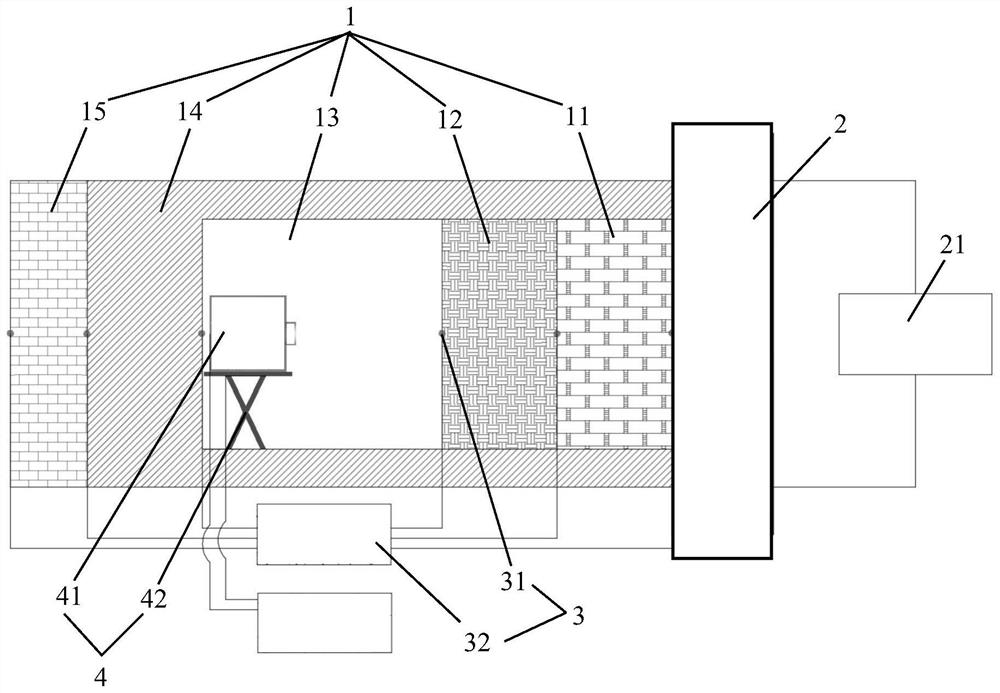

[0061] see attached figure 1 , the embodiment of the present invention discloses a measurement and design system for the thermal insulation structure of a waste incineration boiler furnace wall, including:

[0062] Furnace wall insulation system 1: It is composed of refractory bricks 11, insulation bricks 12, air interlayer 13, insulation layer 14 and red brick layer 15 in any combination;

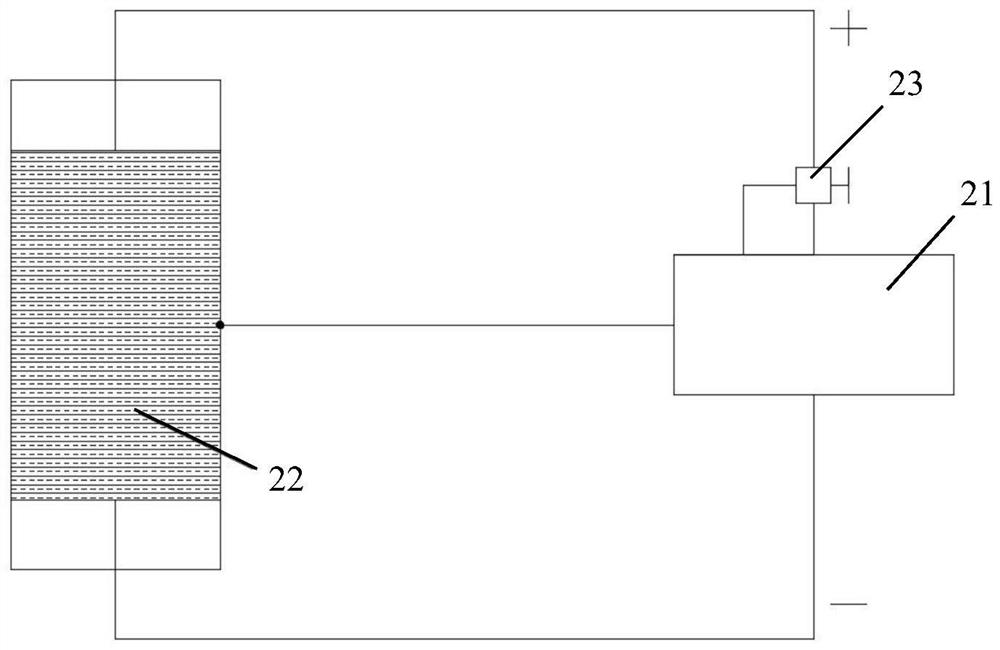

[0063] Heating surface temperature control system 2: used to heat the furnace wall insulation system 1;

[0064] Thermocouple temperature measurement system 3: including a plurality of thermocouple temperature measurement units 31, the thermocouple temperature measurement units 31 are respectively used to measure the surface temperature of the refractory brick 11, the insulation brick 12, the insulation layer 14 and the red brick layer 15, and transmit them to data acquisition instrument 32;

[0065] Infrared thermal imager temperature measurement system 4: including an infrared thermal ...

Embodiment 2

[0074] The embodiment of the present invention discloses a method for measuring and designing the thermal insulation structure of a furnace wall of a waste incineration boiler, which specifically includes the following steps:

[0075] S1. According to the combustion characteristics of different waste incineration boilers, the heating surface temperature control system 2 is heated to the typical outer wall temperature of the heating surface during boiler operation, and the typical outer wall temperature of the heating surface is 400°C, 450°C or 500°C;

[0076] S2, collect and record the data measured by the thermocouple temperature measuring unit 31 through the data acquisition instrument 32, obtain the temperature change curve and change gradient of each layer of the thermal insulation material of the furnace wall thermal insulation system 1 through the computer system, and visually display the thermal insulation properties of the thermal insulation material;

[0077] S3. The i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com