Engine environment thermal resistance coating radiation characteristic research system and method

A technology of radiation characteristics and research system, which is applied in the field of research system of radiation characteristics of thermal resistance coating in engine environment, which can solve problems such as thermal expansion and thermal deformation, coating failure, and low temperature rise rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

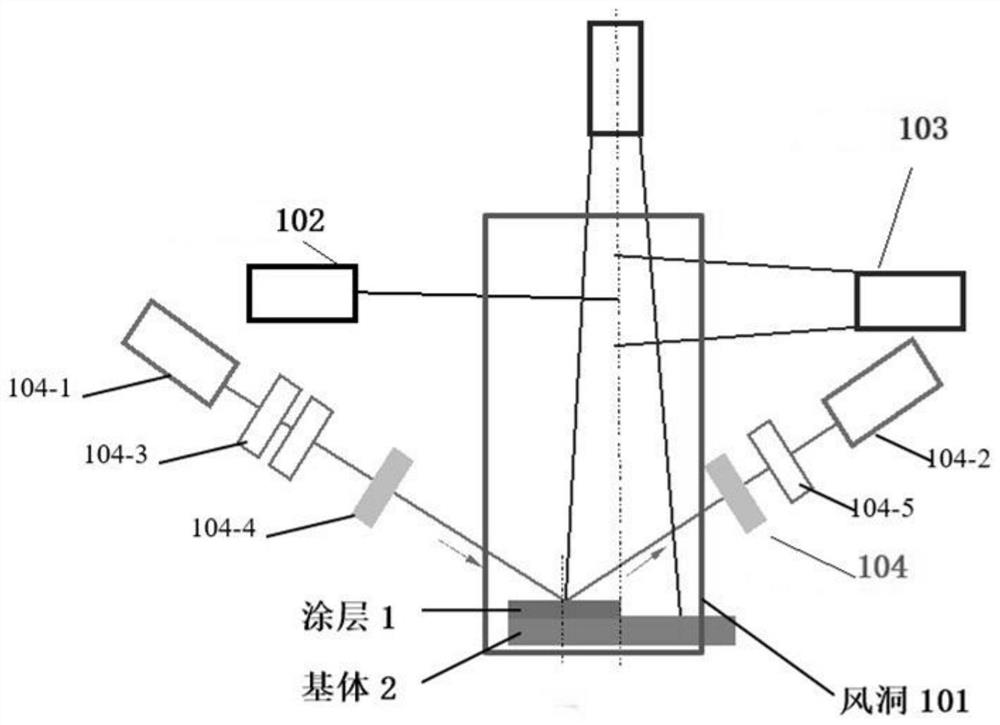

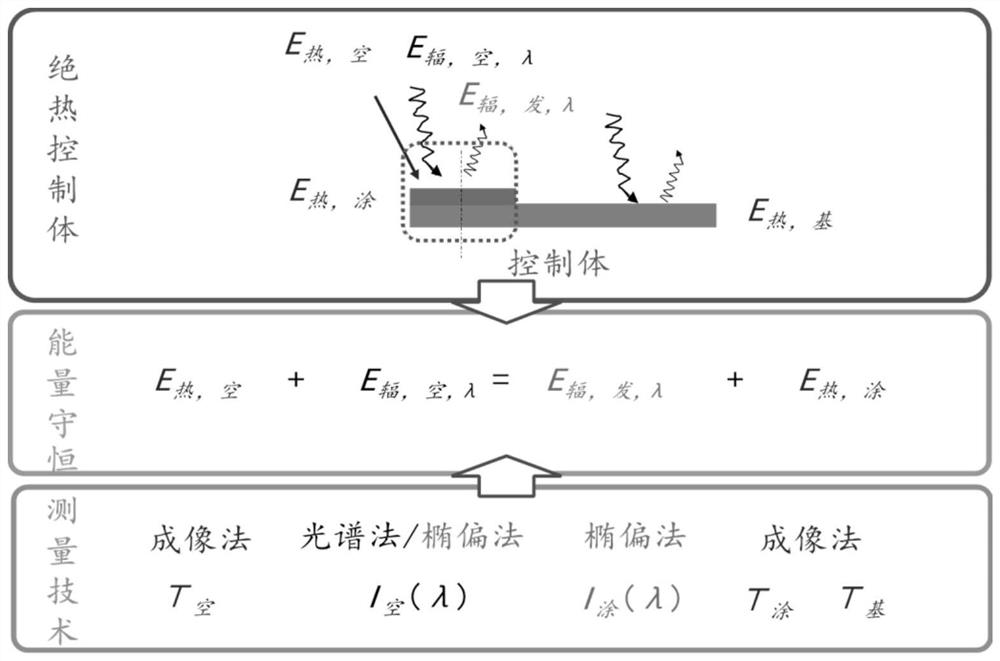

[0041] figure 1 A schematic structural diagram of a thermal radiation measurement system 100 provided for an embodiment of the present invention, as shown in figure 1 As shown, the system includes:

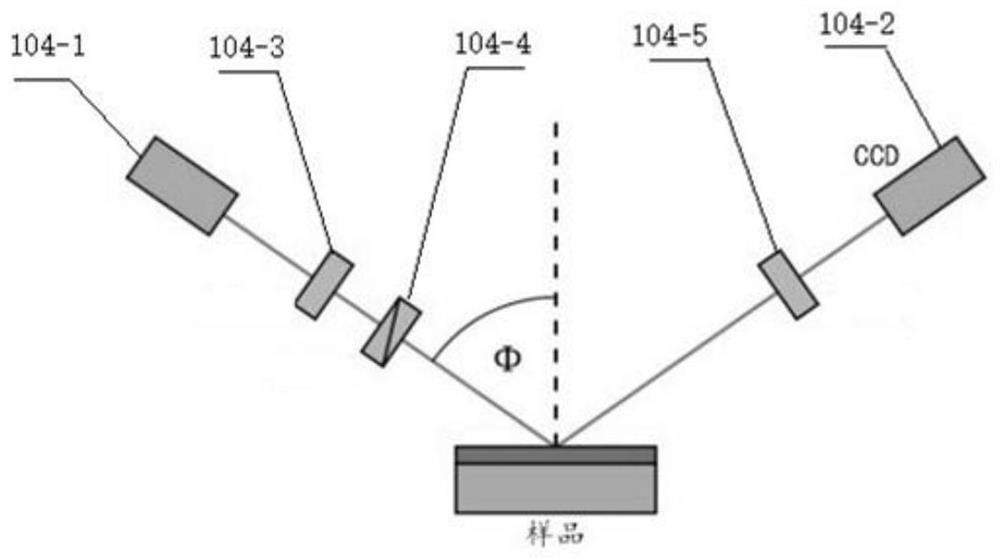

[0042] Wind tunnel 101, Fourier spectrum measuring instrument 102, infrared thermal image measuring instrument 103, infrared ellipsometer 104, Fourier transform spectrometer 102, placed horizontally on one side of wind tunnel 101, infrared thermal image measuring instrument 103 Horizontally placed on the other side of the wind tunnel 101, the incident light system and the receiving and detecting light system of the infrared ellipsometer 104 are symmetrically arranged on both sides of the wind tunnel 101, and the light of the infrared ellipsometer 104 is irradiated on the coating 2 .

[0043] Through the above scheme, the wind tunnel simulates the real engine thermal cycle, quantitatively obtains the transient and steady-state transfer relationship and evolution law between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com