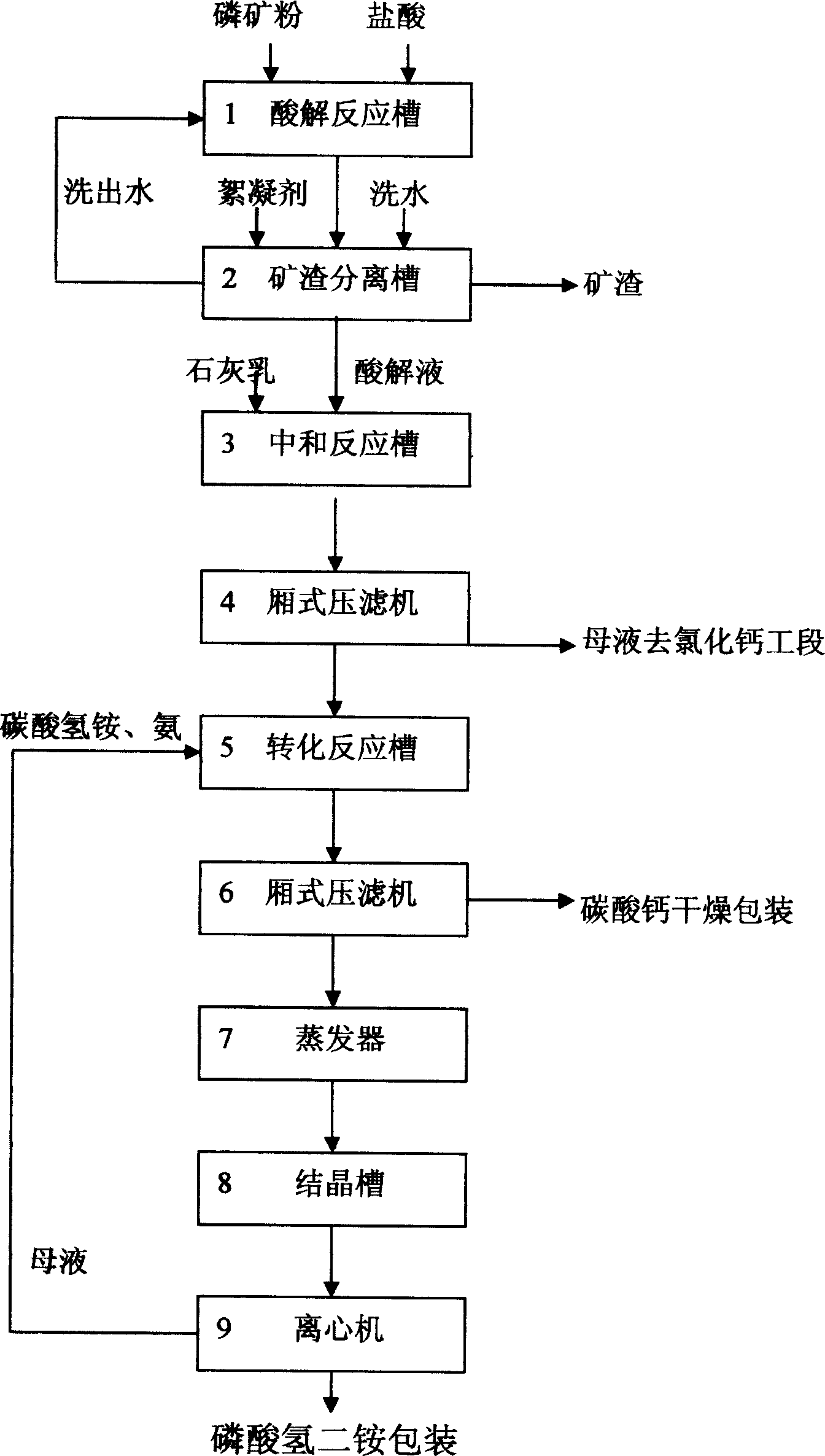

Method for producing phosphate by wet method phosphoric acid purification and hydrochloric acid decomposition for phosphate ore

A wet-process phosphoric acid and phosphate technology, applied in the fields of phosphate, chemical instruments and methods, phosphorus compounds, etc., can solve the problems of impurities interfering with low-grade phosphate rock, etc., and achieve the effect of solving the loss of phosphorus by impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0084] Embodiment: The present embodiment is the phosphorus-containing waste residue that produces in the production process when using agricultural ammonium dihydrogen phosphate and potassium chloride as raw material to produce potassium dihydrogen phosphate for conversion treatment, reclaims P 2 o 5 the experimental results. at 3m 3 In the stirred reaction vessel, add circulating phosphorus-containing slag conversion washing solution 2m 3 (P 2 o 5 =65.140g / l), add the phosphorus-containing waste residue 1000kg (P 2 o 5 =21.31%), add 230kg of ammonium bicarbonate, stir and react at 30-40°C for 1 hour, and feed ammonia gas to keep the pH of the reaction material=7.5-8.0. After the reaction is completed, filter and wash the filter cake. Obtain filtrate (add one washing water) 2.60 cubic meters, P 2 o 5 =131.53g / l, Fe in solution 2 o 3+Al 2 o 3 +CaO+MgO≤0.00015g / l. P in filtered calcium carbonate 2 o 5 =0.28% (calculated on a dry basis). The recovered solution i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com