Battery cell series connection module support, and battery cell series connection module and assembling method thereof

A technology of connecting modules and cells in series, applied in battery pack parts, circuits, electrical components, etc., can solve problems such as easy short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

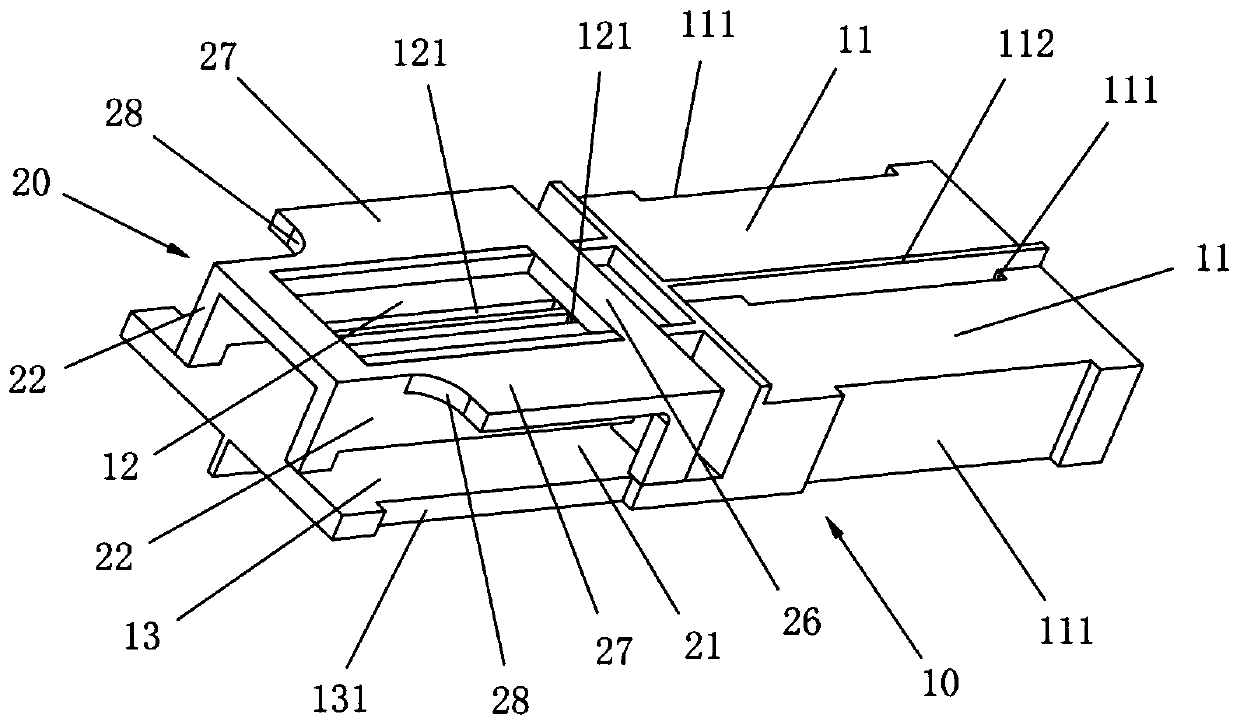

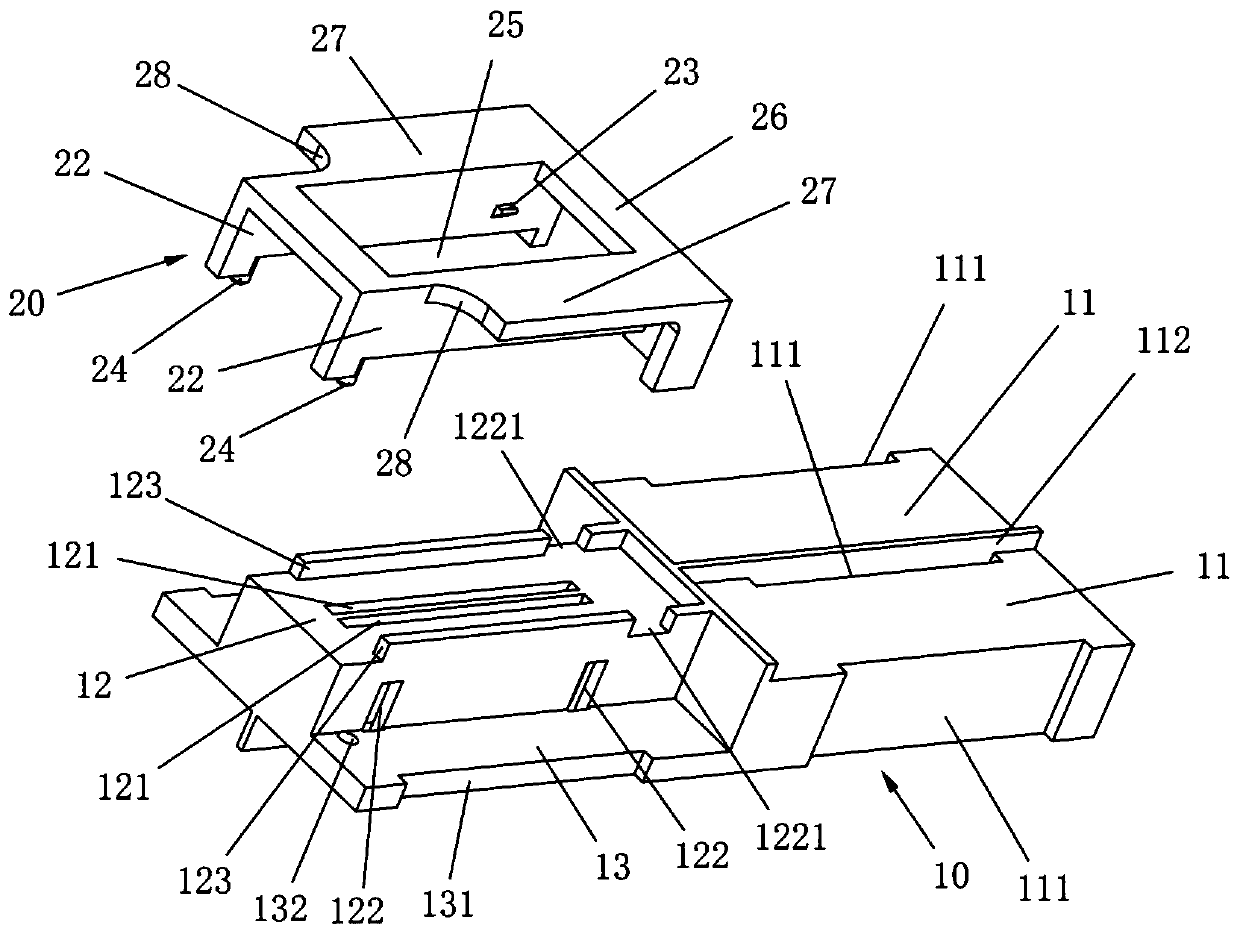

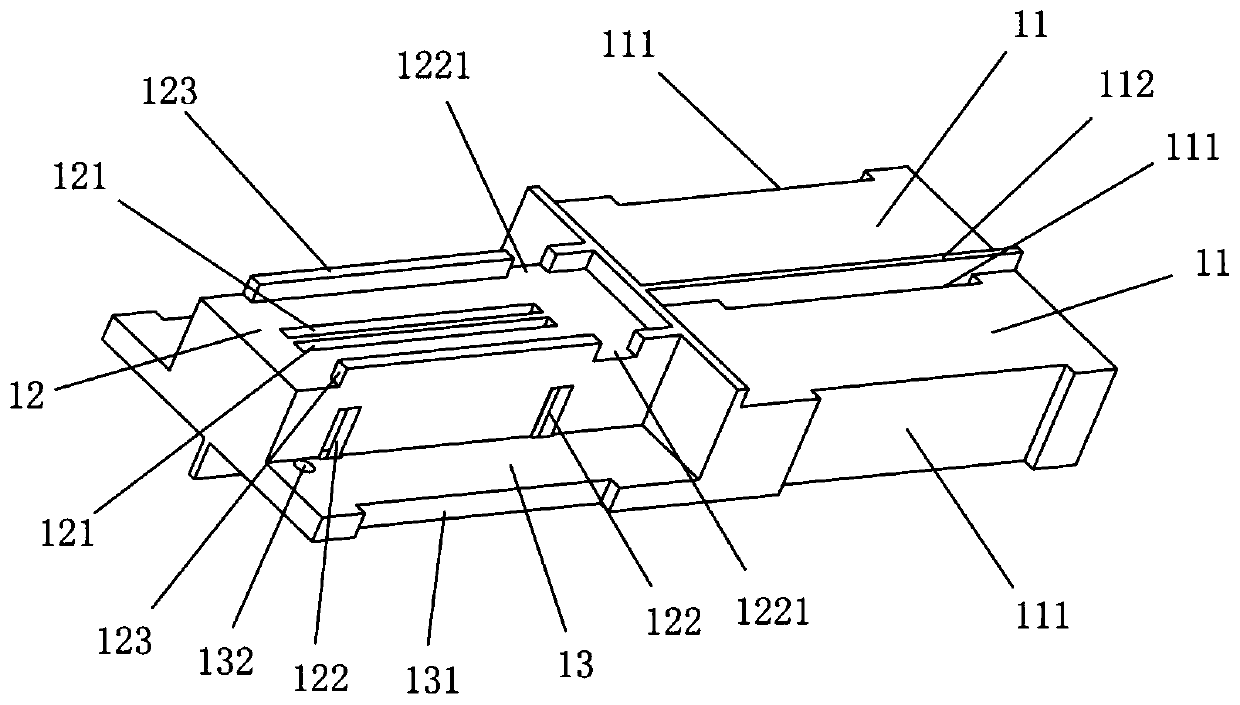

[0034] see Figure 1 to Figure 4 , a cell series module bracket according to an embodiment of the present invention, the cell series module bracket is a battery cell 4-series module bracket (4 single cells 40 are connected in series to form a battery module). It can be seen from the figure that the cell series module bracket mainly includes: a module bracket main body 10 and a module crimping cover 20 . Wherein, one end of the main body 10 of the module bracket is provided with a plurality of first tab welding platforms 11, and each first tab welding platform 11 is provided with a first tab welding through groove 111 on both sides, and the adjacent first tab welding platforms 11 A tab welding platform 11 is separated by a partition 112; the other end of the module support body 10 is provided with a second tab welding platform 12, and a plurality of second poles are provided on the second tab welding platform 12. The lug welding through groove 121, the two sides of the second ...

Embodiment 2

[0042] see Figure 5 to Figure 12 , a battery cell series module according to an embodiment of the present invention, specifically, the battery cell series module bracket is a battery cell 4-series module. It can be seen from the figure that the cell series module mainly includes: a cell series module bracket, positive and negative power lines 30 and multiple cells 40 .

[0043] Wherein, the battery cell series module bracket is the battery cell series module bracket in Embodiment 1; multiple battery cells 40 are stacked with different polarities (that is, the positive pole of one battery cell 40 is positively connected to the negative pole of the adjacent battery cell 40). Yes, its negative pole is opposite to the positive pole of the adjacent electric core 40); the first tabs 41 at one end of the multiple electric cores 40 protrude from the plurality of first tab welding slots 111 respectively, and are bent and welded in pairs Above the first lug welding platform 11; the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com