Firefighting blasting and breaking system used for building glass

A technology for architectural glass and fire protection, which is applied in blasting, building rescue, life-saving equipment, etc., and can solve problems affecting fire protection, escape, smoke emission, and wall glass that cannot be blasted in time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

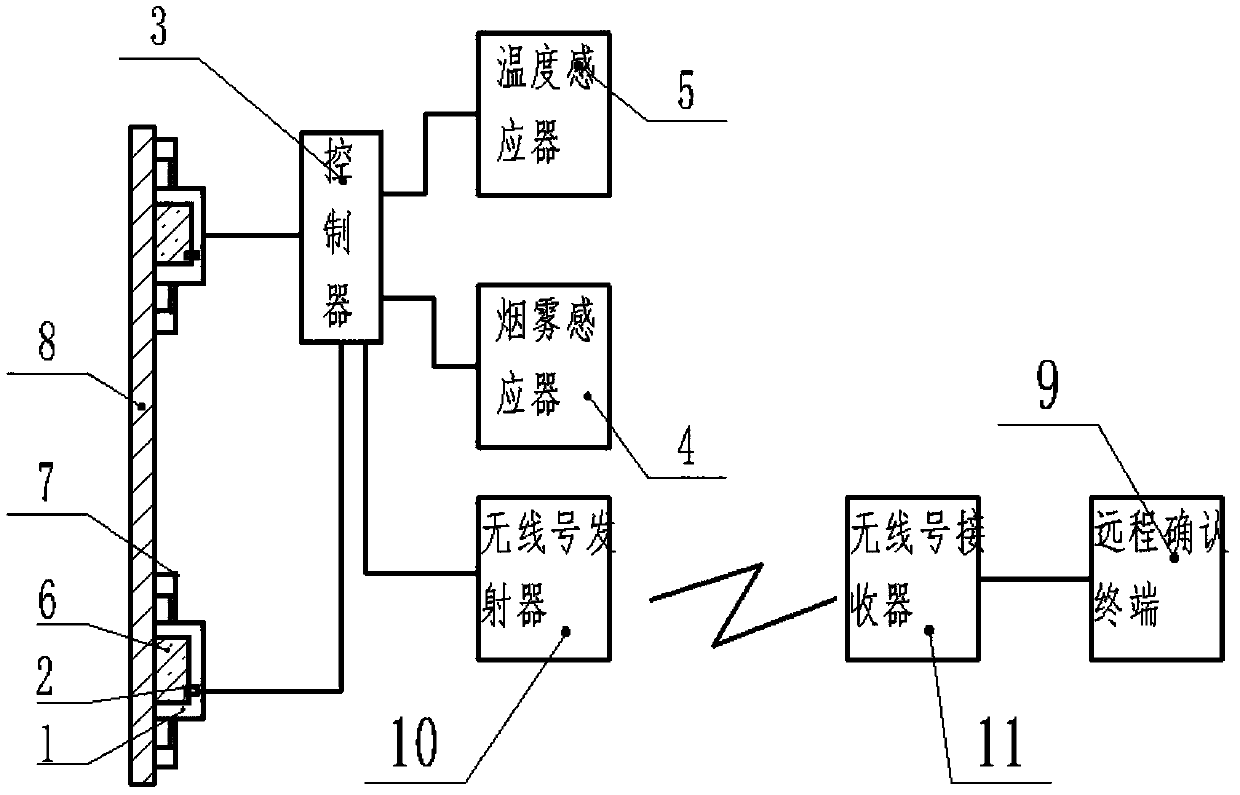

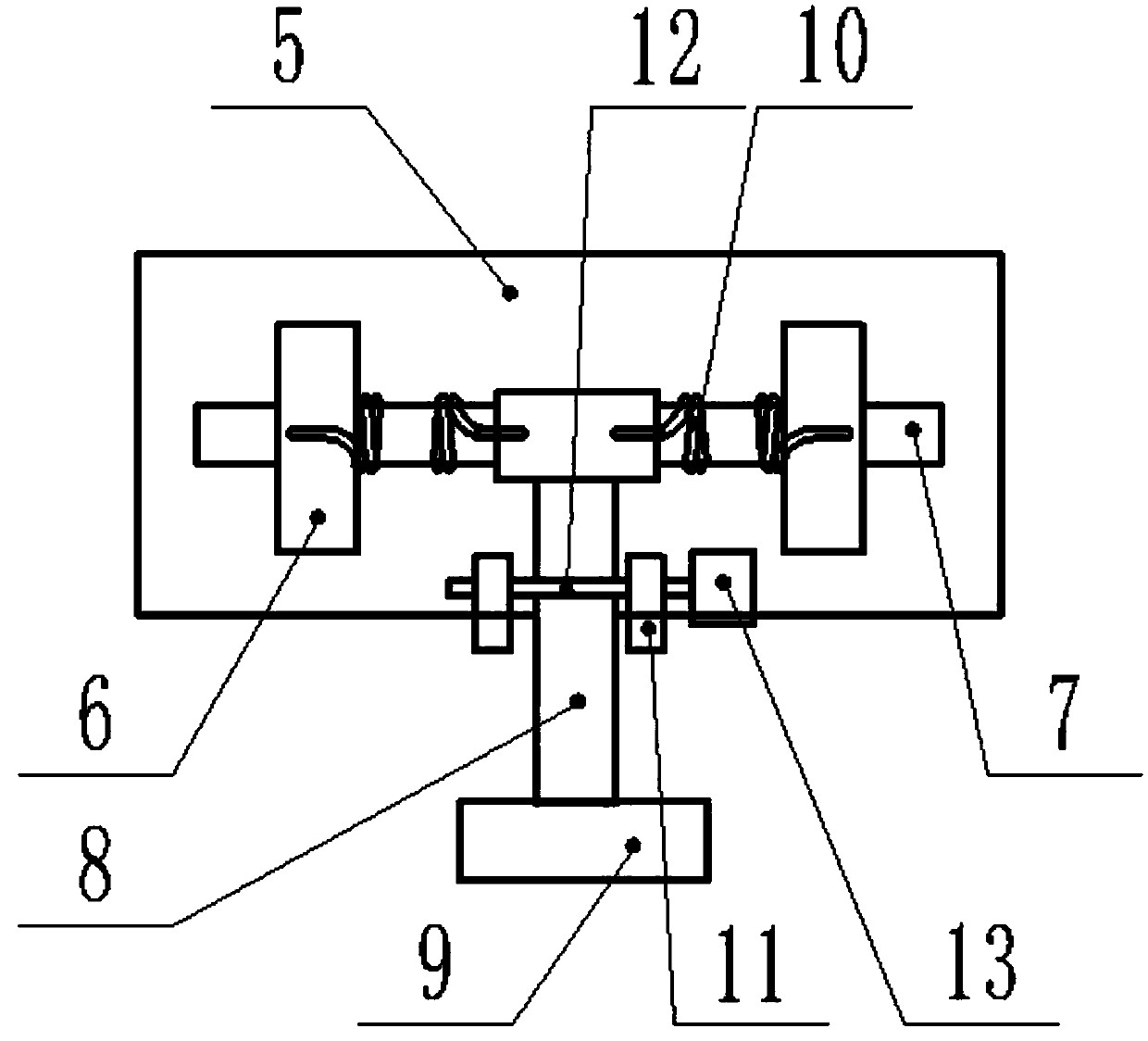

[0023] Such as Figure 1-2 As shown, the present invention is a fire-fighting blasting and breaking system for architectural glass, comprising a powder cavity (1), a detonating core (2), a controller (3), a smoke sensor (4), a temperature sensor ( 5), the catapult (1) and the remote confirmation terminal (9), are characterized in that: the gunpowder chamber (1) is a groove structure, the gunpowder chamber (1) is equipped with gunpowder (6), and the gunpowder chamber The body (1) is surrounded by a plurality of suction cup holders (7), the gunpowder chamber (1) is adsorbed on the glass (8) through the suction cup holders (7), and the opening of the gunpowder chamber (1) corresponds to the glass (8) , a detonating core (2) for detonating the propellant (6) is provided in the propellant cavity (1), and the detonating core (2) is connected to the controller (3) for control, and the controller (3) is respectively connected with smoke sensor (4) and temperature sensor (5);

[0024...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com