Protective cover for electric welding machine

A technology of electric welding machine and protective cover, which is applied in the field of protective cover, which can solve the problems of reducing the service life of electric welding machine, bruises, objects smashed, etc., and achieve the effect of avoiding the sun and rain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

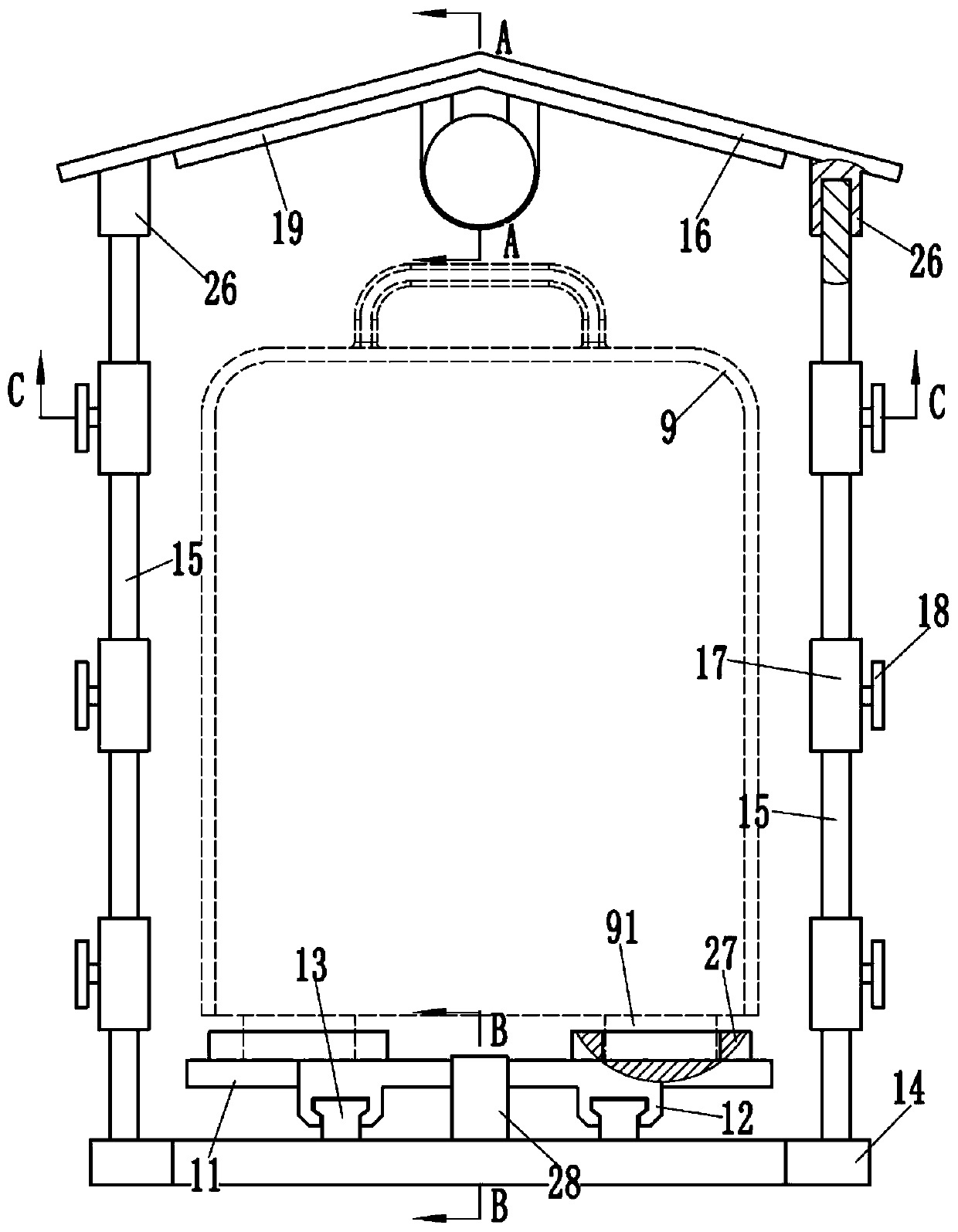

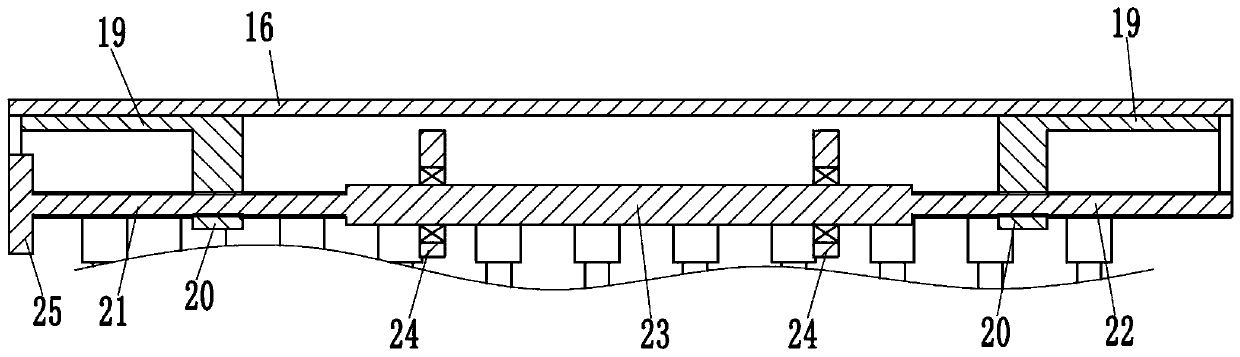

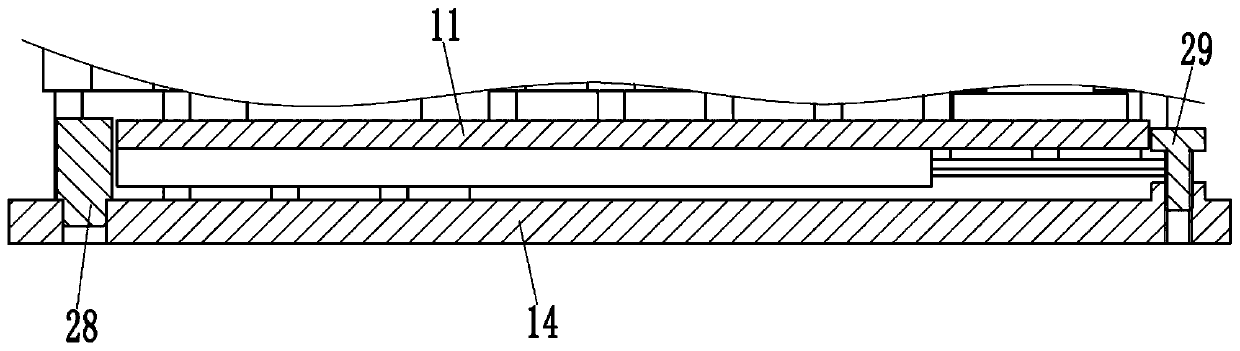

[0018] Examples, see e.g. Figure 1 to Figure 4 As shown, a protective cover for an electric welding machine includes a support base 11 for placing an electric welding machine 9, and two sliders 12 arranged left and right are fixed on the lower bottom surface of the support base 11, and each slider 12 slides Connected to the corresponding slide rail 13, the slide rail 13 is fixed on the base plate 14, and the left and right sides of the base plate 14 are respectively fixed with a row of protection rods 15 linearly and uniformly distributed in the front and rear directions, and the tops of the two rows of protection rods 15 are connected There is the protective plate 16 that is triangular eaves shape.

[0019] Furthermore, each column of protective bars 15 is sleeved with a plurality of side bars 17 linearly and uniformly distributed in the up and down direction, and the side bars 17 can slide up and down on the protective bars 15; A locking screw 18 is screwed, and the end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com