Wire joint tin hanging device for indoor decoration

A technology for wire joints and interior decoration, applied in coating, metal material coating process, hot dip plating process, etc., can solve the problems of cumbersome, difficult to spill tin liquid, etc., to achieve the effect of convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

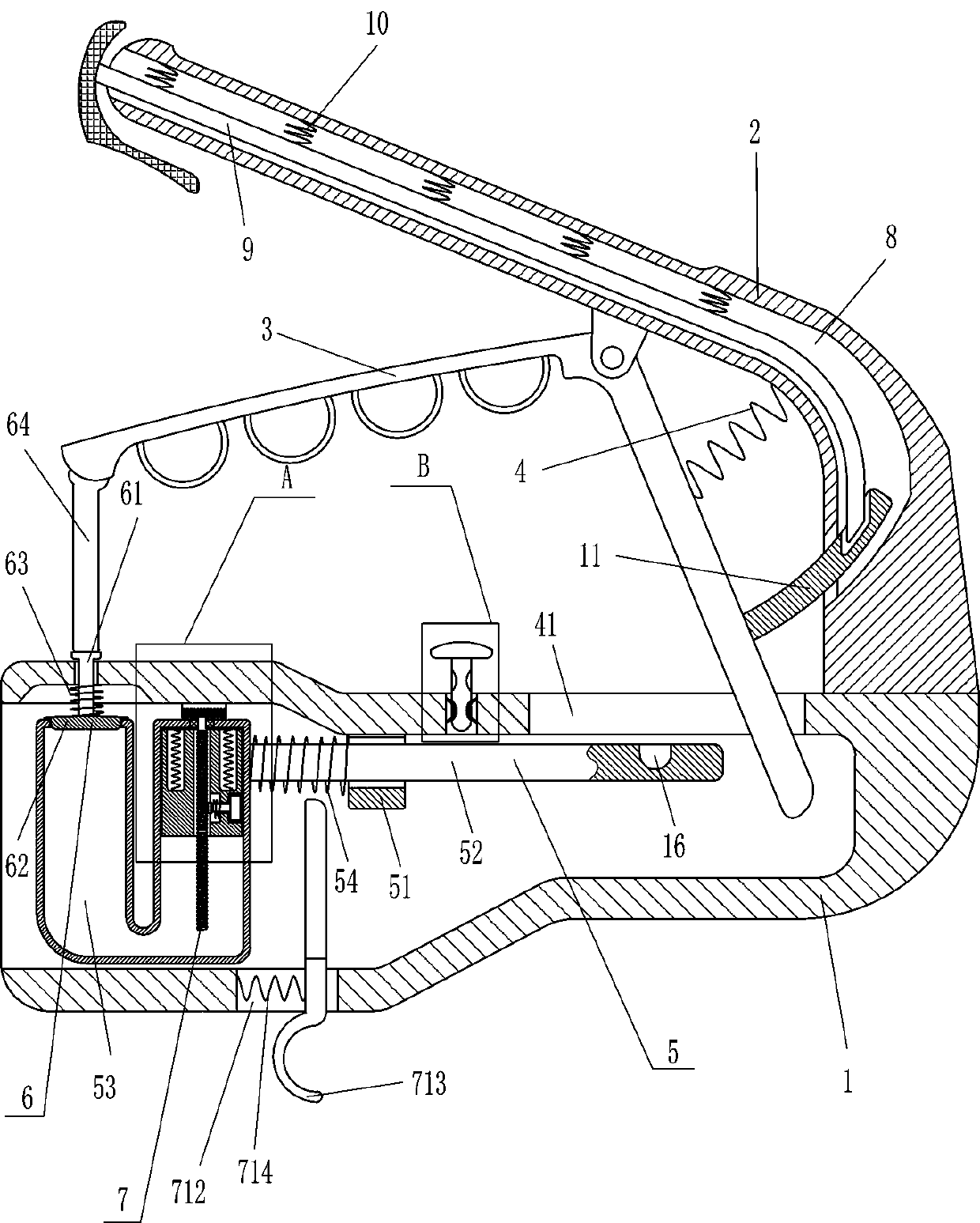

[0021] A wire connector hanger for interior decoration, such as Figure 1-2 As shown, it includes a cylinder body 1, a fixed handle 2, an L-shaped handle 3, a first spring 4, a material storage device 5 and a sealing device 6, the fixed handle 2 is installed on the top right of the cylinder body 1, and the left part of the cylinder body 1 is Open, the fixed handle 2 is equipped with an L-shaped handle 3 through a hinged connection, the first spring 4 is connected between the L-shaped handle 3 and the inner left side of the fixed handle 2, and an opening 41 is opened on the right side of the top of the cylinder 1 , the bottom of the L-shaped handle 3 passes through the opening 41 and is located in the cylinder 1, the cylinder 1 is provided with a storage device 5, wherein the storage device 5 is used to store tin liquid, and the left part of the cylinder 1 is provided with a sealing device 6, wherein the sealing device 6 is used to seal the storage device 5 .

[0022] The stor...

Embodiment 2

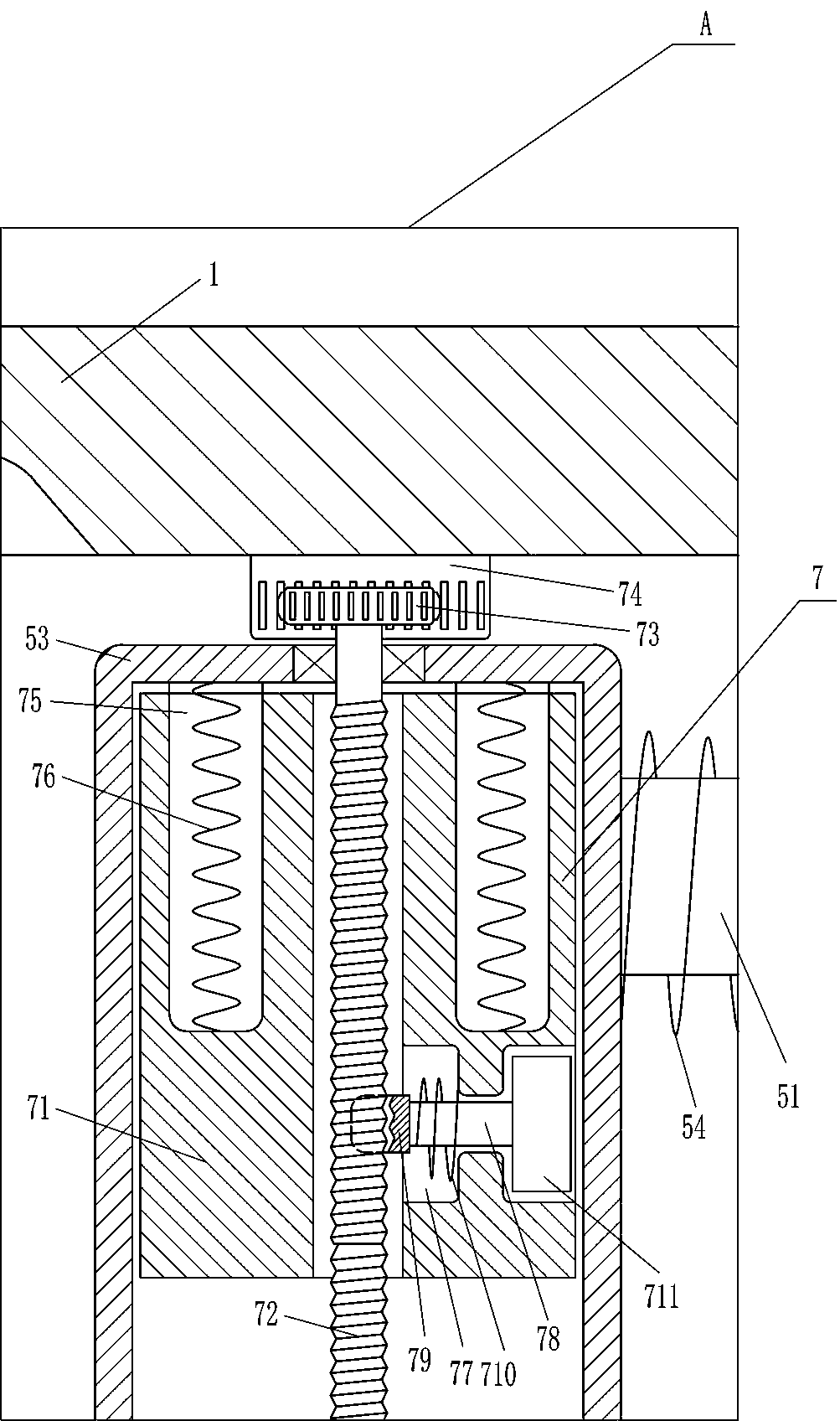

[0026] On the basis of Example 1, such as Figure 1-2Shown, also comprise limit device 7, limit device 7 comprises hollow sliding block 71, threaded rod 72, ratchet 73, tooth bar 74, the 4th spring 76, horizontal movable bar 78, half nut 79, the 5th spring 710 , fixed high-temperature magnet 711, movable high-temperature magnet 713 and the sixth spring 714, U-shaped heating cylinder 53 right side sliding type is provided with hollow sliding block 71, and U-shaped heating cylinder 53 right side upper rotating type is connected with threaded rod 72, threaded rod 72 is located in the hollow sliding block 71, a ratchet 73 is installed on the top of the threaded rod 72, a rack 74 is installed on the inner top of the left side of the cylindrical body 1, the rack 74 is engaged with the ratchet 73, and vertical holes are opened on the left and right sides of the top of the hollow sliding block 71. Straight opening 75, a fourth spring 76 is connected between the bottom of the vertical ...

Embodiment 3

[0029] On the basis of Example 2, such as Figure 1-3 Shown, also comprise special-shaped bar 9, the 7th spring 10 and the first clamp bar 11, have special-shaped opening 8 in fixed handle 2, be provided with special-shaped bar 9 movablely in special-shaped opening 8, special-shaped bar 9 tops and Seventh springs 10 are evenly spaced between the tops of the special-shaped openings 8, and the outer right side of the L-shaped handle 3 is equipped with a first clamping rod 11, which cooperates with the special-shaped rod 9.

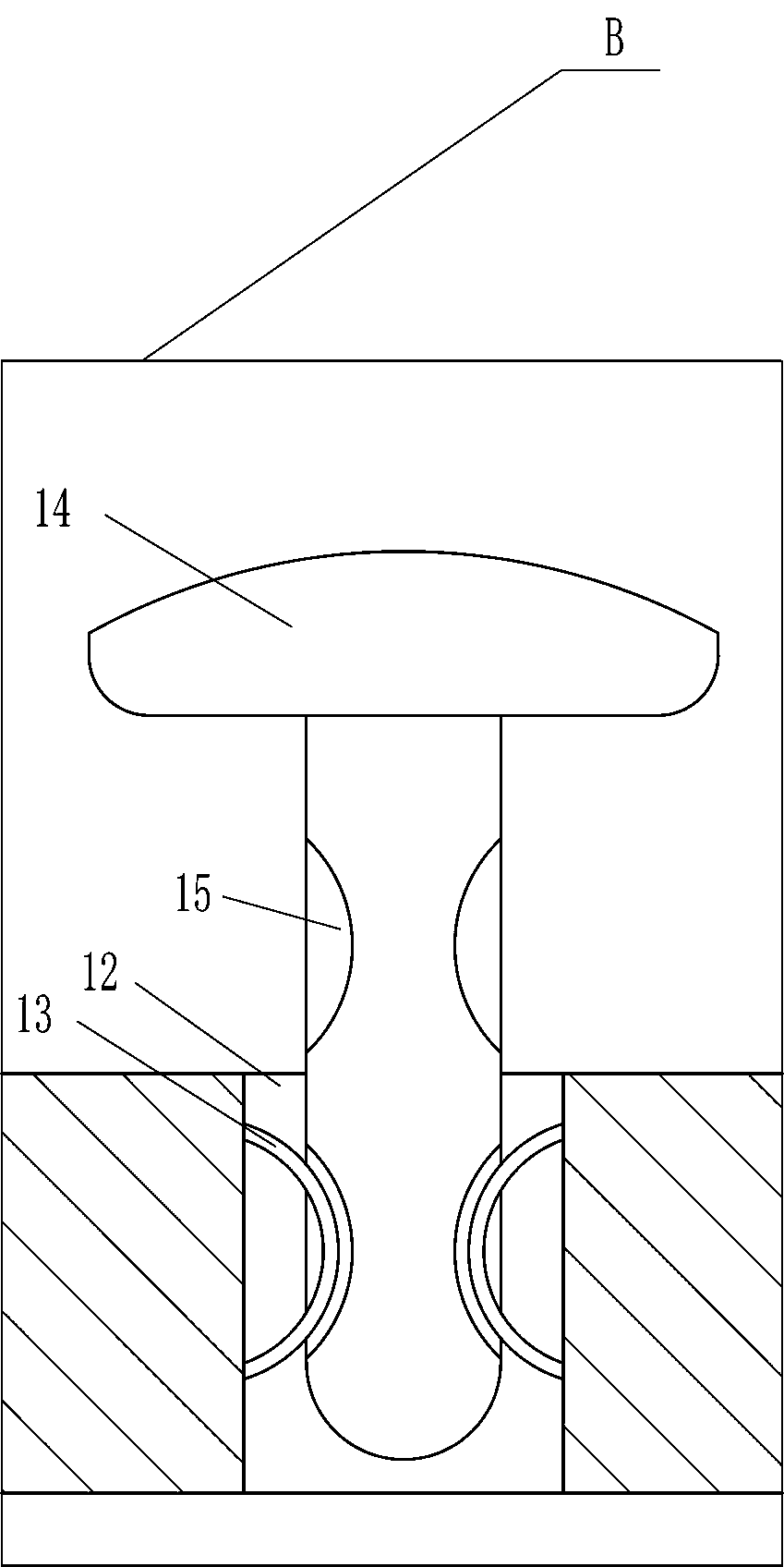

[0030] It also includes an arc-shaped reed 13 and a second clamping rod 14. There is a vertical hole 12 in the middle of the upper part of the cylinder body 1. The left and right sides of the vertical hole 12 are provided with arc-shaped reeds 13. The vertical hole 12 is slidingly provided with The second clamping rod 14 has a groove 15 matching with the arc-shaped reed 13 on the second clamping rod 14 , and a clamping hole 16 matching with the second clampi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com