Water pump axial force self-balancing device

An axial force, self-balancing technology, applied to the components, pumps, pump components, etc. of the pumping device for elastic fluid, can solve the problems of motor damage, loss, large axial force, etc., and achieve reasonable design and structure. novel effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

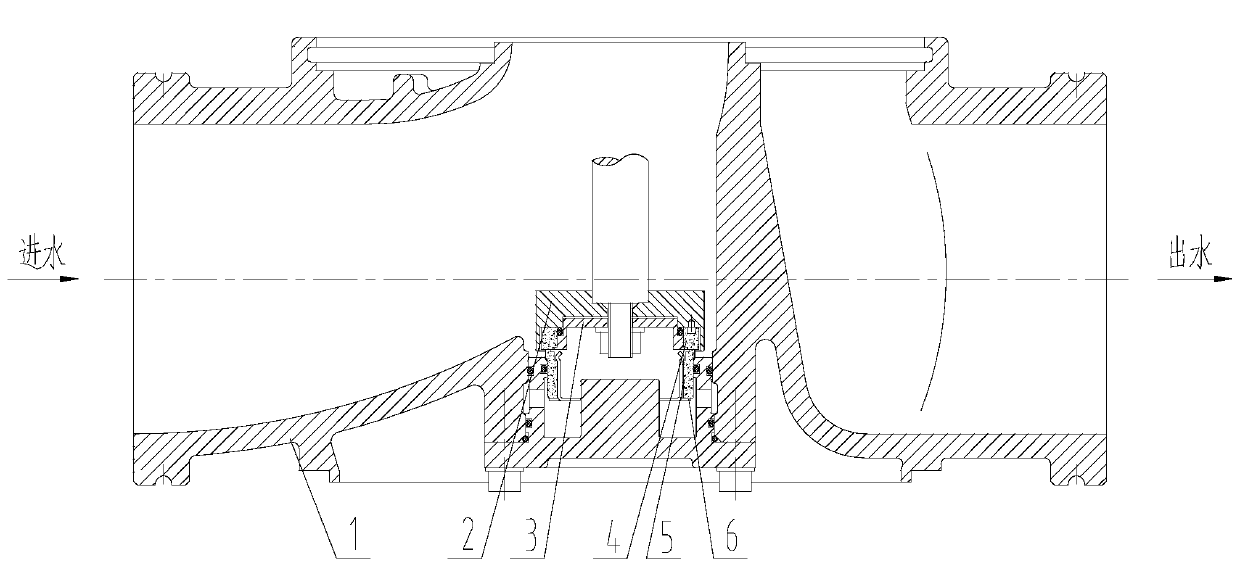

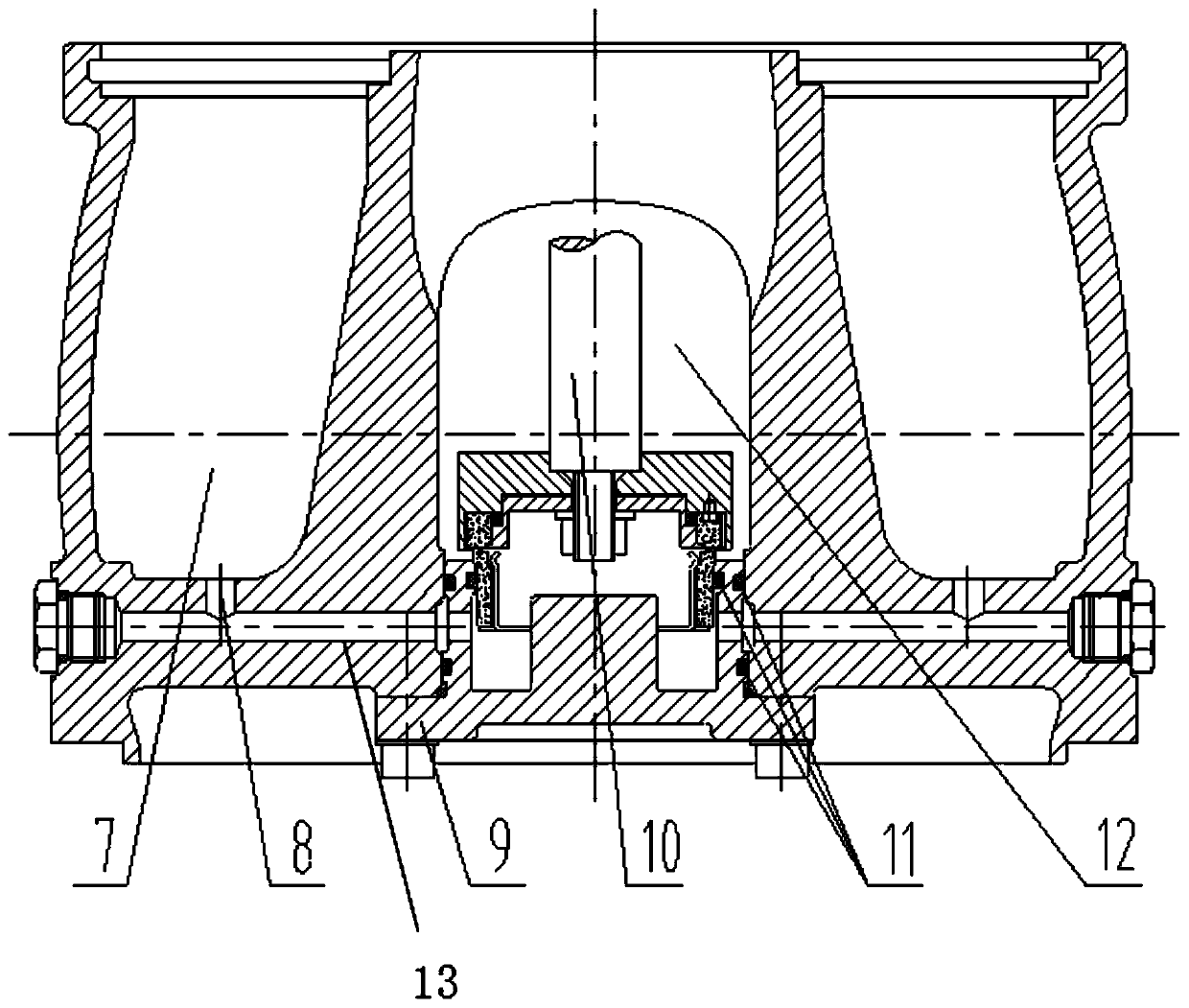

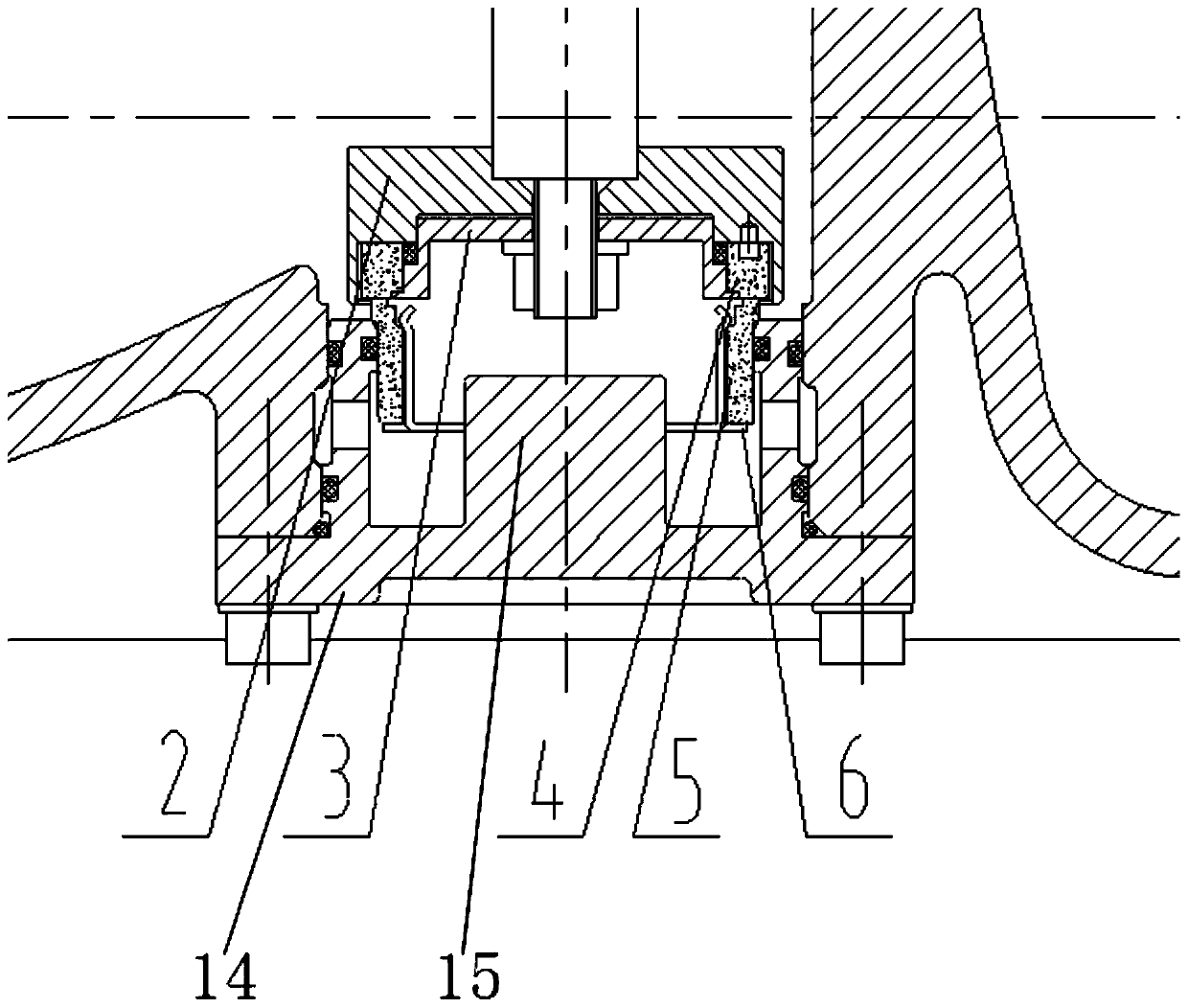

[0014] Below in conjunction with accompanying drawing, the present invention will be further described as follows:

[0015] As shown in the drawings, the present invention provides a water pump axial force self-balancing device, including a water pump inlet and outlet section 1, the water pump inlet and outlet section 1 is divided into a high pressure area 7 and a low pressure area 12, and the bottom of the high pressure area 7 is provided with a return hole 8. The return hole 8 communicates with the return channel 13 of the water pump inlet and outlet section 1. The high-pressure water flow in the high pressure area 7 flows to the low pressure area 12 through the return hole 8 and the return channel 13. The water pump inlet and outlet section 1 is provided with a balance seat 9 to balance The seat 9 is set under the pump shaft 10, the balance seat 9 is provided with a lifting plate 6, the lifting plate 6 is set at the bottom of the low-pressure area 12, the lifting plate 6 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com