Butt joint type stress sensor

A stress sensor and docking technology, which is applied in the direction of instruments, measuring force, measuring devices, etc., can solve the problems of compatibility, functional film layer falling off, and inability to be used for multiple cleaning cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] To further illustrate the various embodiments, the present invention is provided with accompanying drawings. These drawings are a part of the disclosure of the present invention, which are mainly used to illustrate the embodiments, and can be combined with related descriptions in the specification to explain the operating principles of the embodiments. With reference to these contents, those skilled in the art should understand other possible implementations and advantages of the present invention.

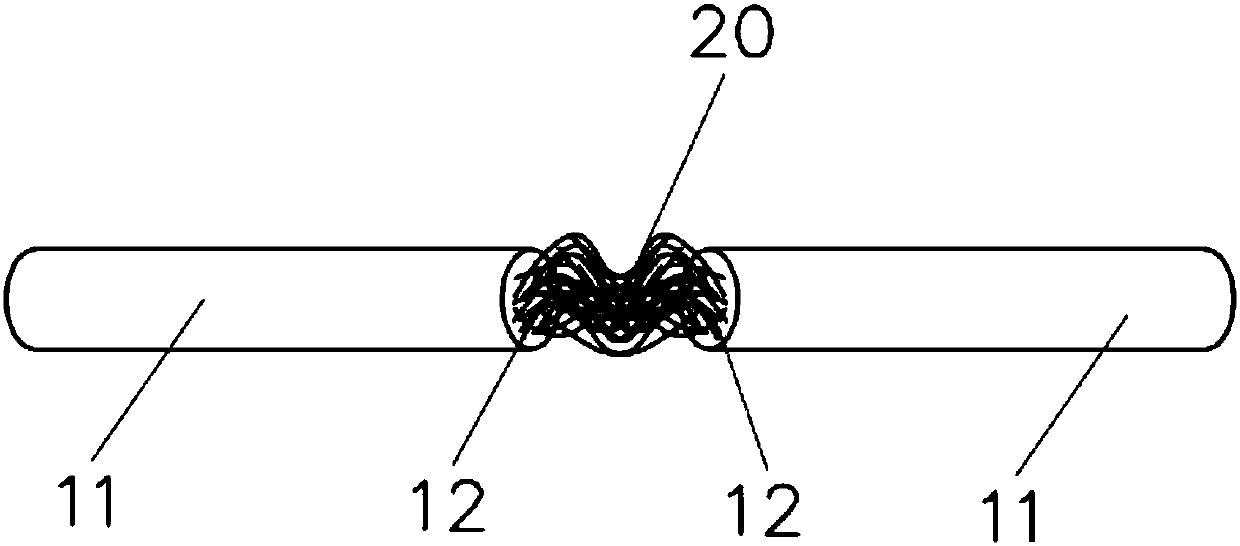

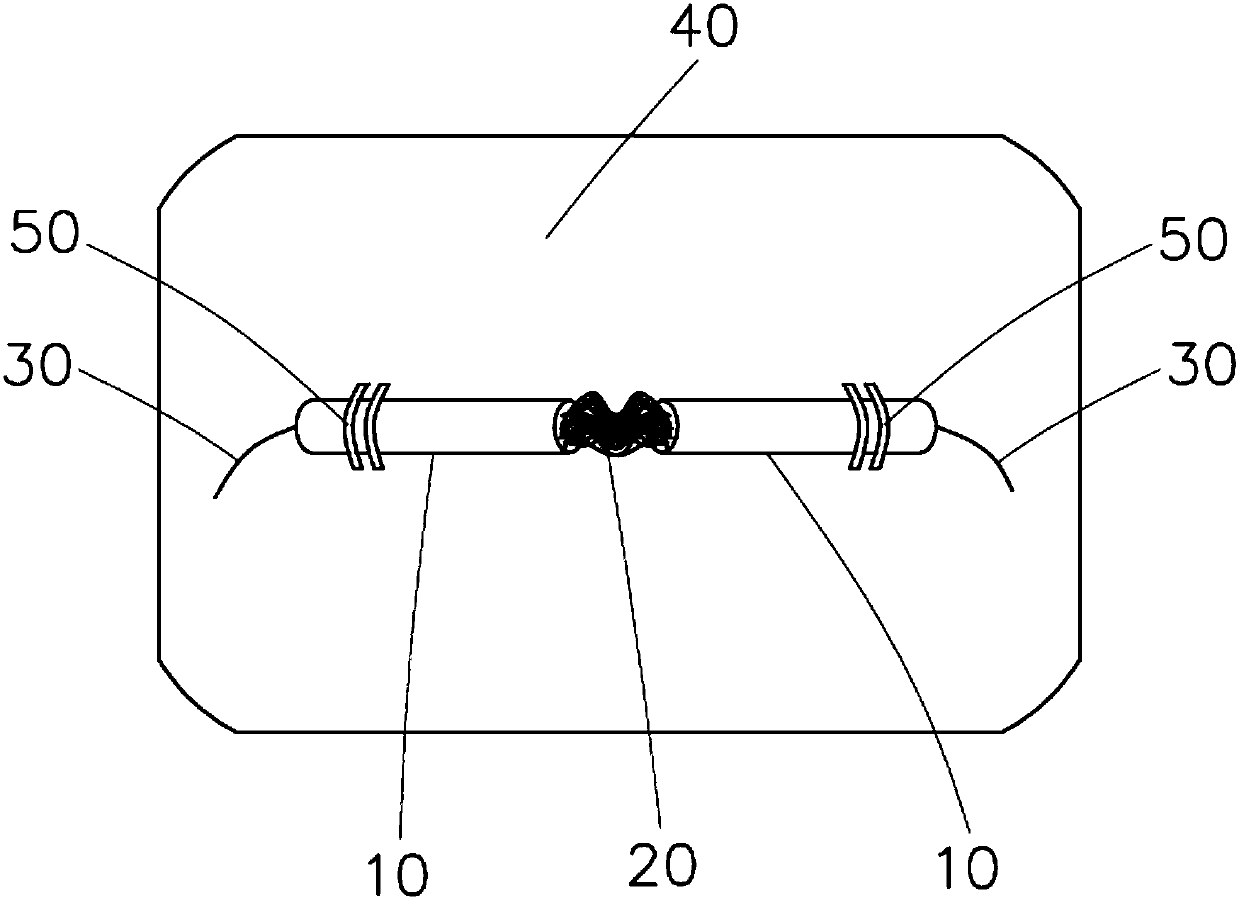

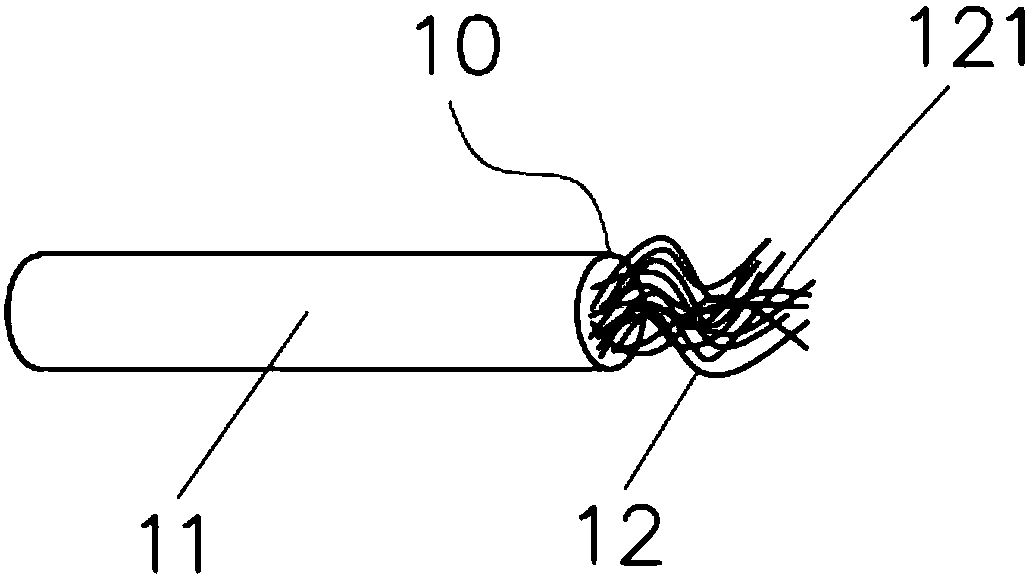

[0026] Please also see Figure 1 to Figure 3 .

[0027] The docking type stress sensor of the present invention includes two conductive fiber bundles 10, each conductive fiber bundle 10 includes a converging portion 11 and a fluffy structure 12 electrically connected to the converging portion 11; the fluffy structure of the two conductive fiber bundles 10 12 are butted against each other to form a butt joint 20, and the converging portions 11 of the two conductive fiber b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com