Bearing carrier of magnetic circuit assembly of bone conduction earphone and automatic assembly equipment thereof

A bone conduction earphone and automatic assembly technology, applied in earphone/earphone accessories, sensor parts, sensors, etc., can solve the problem of large assembly error assembly requirements, reduce the assembly quality of magnetic circuit components, etc., and achieve the effect of improving assembly quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

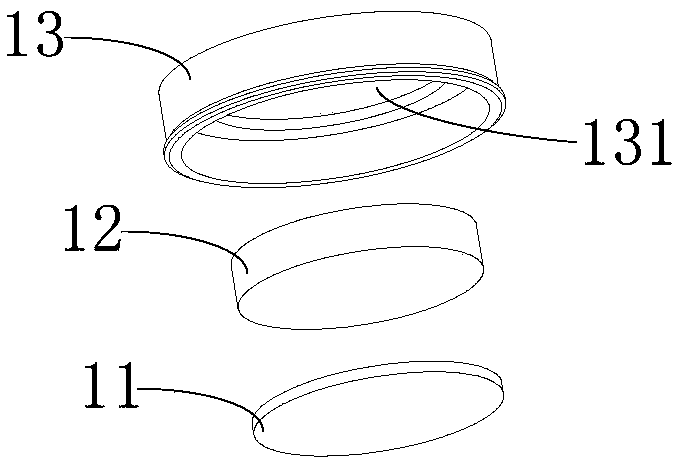

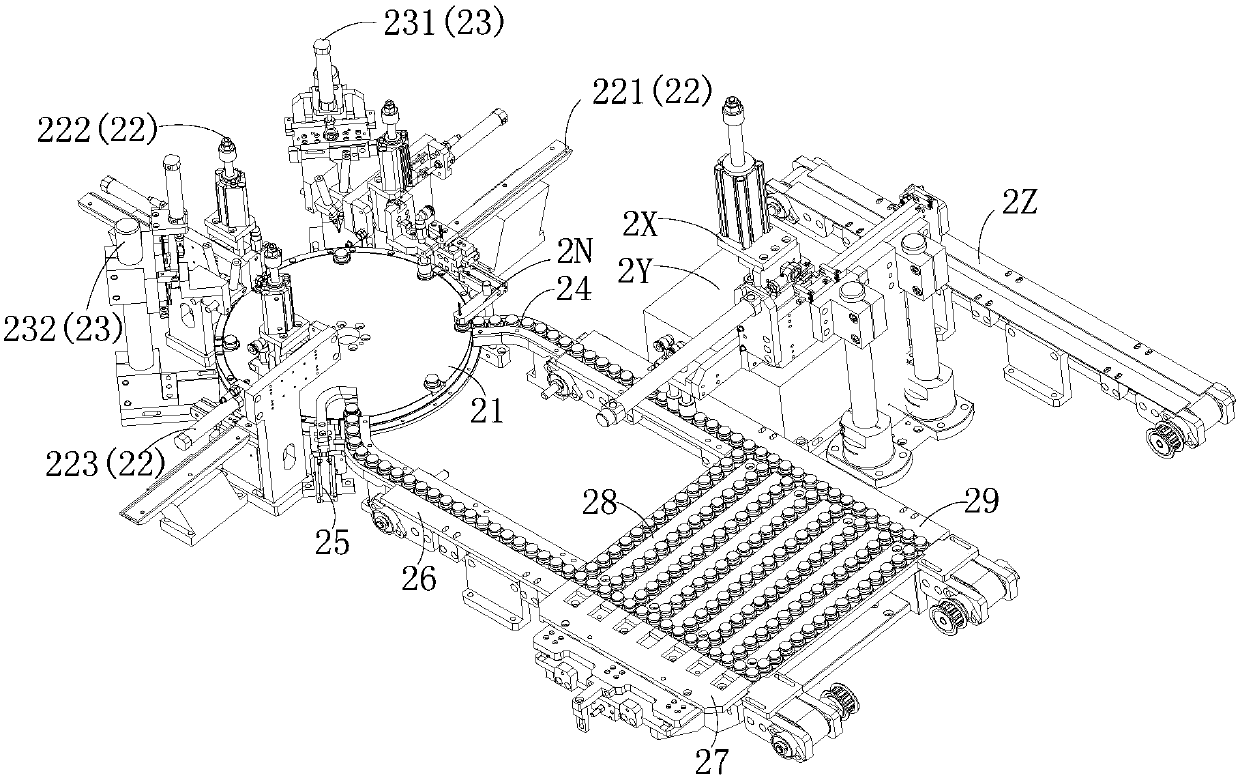

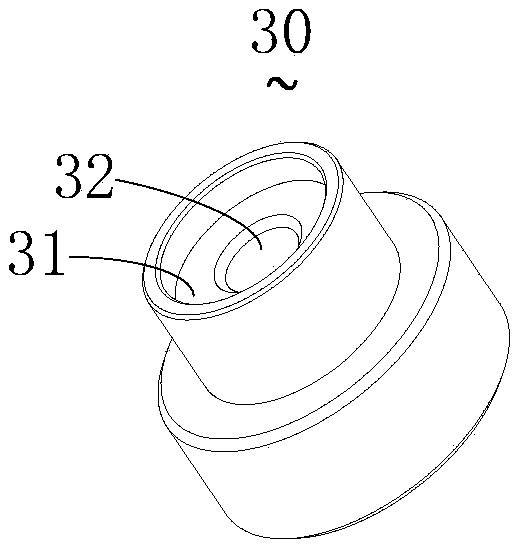

[0026] Please also refer to Figure 1 to Figure 3 , figure 1 It is a structural schematic diagram of the magnetic circuit assembly of the bone conduction earphone of the present application, figure 2 It is a structural schematic diagram of an embodiment of the automatic assembly equipment for the magnetic circuit assembly of the bone conduction earphone of the present application, image 3 It is a structural schematic diagram of an embodiment of a carrier for carrying a magnetic circuit assembly of a bone conduction earphone according to the present application.

[0027] Among them, the magnetic circuit component is the part of the bone conduction earphone to realize the electric-force transduction, and it is an indispensable part in the whole electric-force-acoustic transduction process of the bone conduction earphone. In this application, the magnetic circuit assembly of the bone conduction earphone includes a magnetically conductive plate 11 , a magnetized plate 12 , and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com