Robot driving joint

A technology of robots and joints, applied in the direction of manipulators, manufacturing tools, joints, etc., can solve the problems of increasing the vibration and noise of the transmission system, reducing the life of transmission components and system reliability, so as to avoid system vibration and noise and reduce noise transmission and radiation, the effect of the overall structure is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

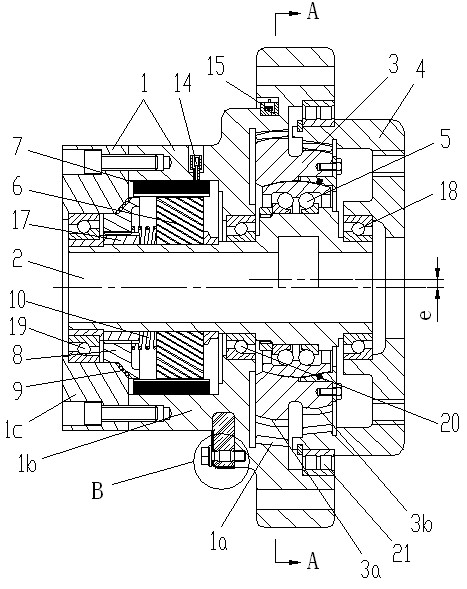

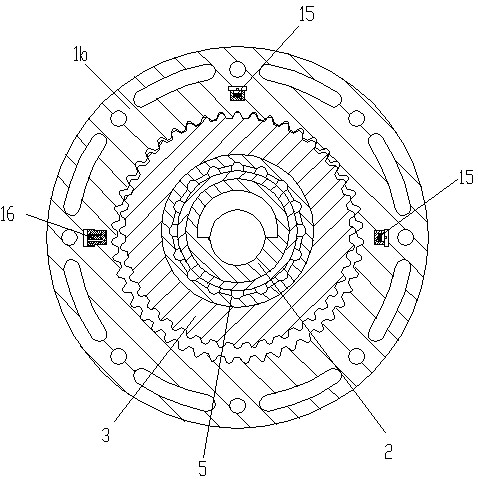

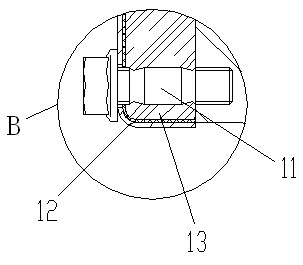

[0031] figure 1 It is a sectional view of the overall structure of the robot drive joint of the present invention; figure 2 for figure 1 Sectional view along A-A; image 3 for figure 1 The enlarged schematic diagram of part B in the middle.

[0032] As shown in the figure, the robot drive joint in this embodiment includes a drive joint housing 1, a power input shaft 2, a double-connected outer arc-shaped drum tooth 3, and a power output gear 4 with an inner arc-shaped drum gear.

[0033] The drive joint housing 1 is provided with an inner arc-shaped drum gear 1a,

[0034] The first rolling bearing 5 is fixedly overlaid on the power input shaft 2, and the first rolling bearing 5 is eccentrically arranged with the power input shaft, and the eccentricity is e. The double-connected outer arc-shaped bulging teeth 3 are overlaid on the first rolling bearing and coaxial with it set up,

[0035] The first drum-shaped tooth 3a of the double-connected outer arc-shaped drum gear 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com