Assembly tool for rethresher shell of harvester

A technology for assembly tooling and re-extractors, applied in the direction of manufacturing tools, auxiliary devices, metal processing equipment, etc., can solve the problems of low assembly efficiency, achieve the effects of improving assembly efficiency, reducing assembly errors, and preventing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

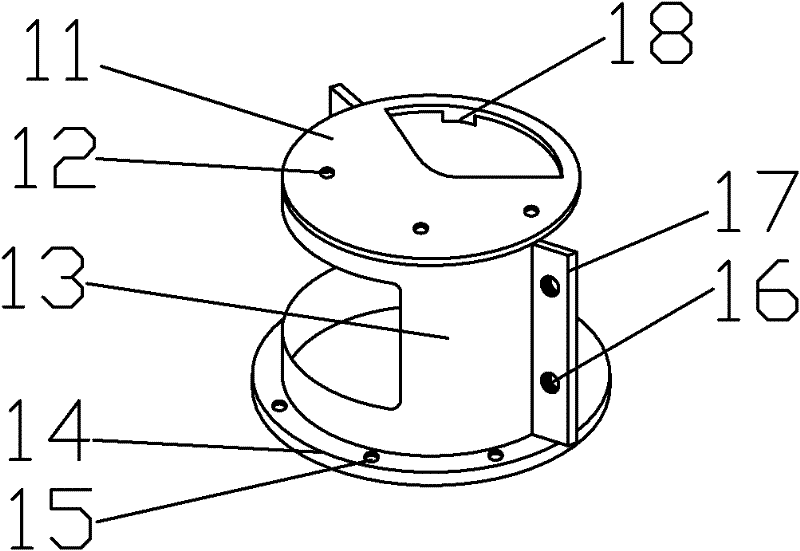

[0018] Such as figure 2 As shown, the shell of the harvester re-extractor includes a volute 13, an end cover 11 welded on one side of the volute 13, and a flange 14 welded on the other side of the volute 13. The shape of the volute 13 is not It is completely cylindrical and forms the interface of the grain output tube connected with the grain output tube of the harvester. The two edges of the outer curved surface of the volute 13 are bent outward to form two connecting plates 17 for connecting with the grain output tube. Each connecting plate 17 is provided with Two threaded holes 16. The shape of the end cover 11 is disc-shaped, and an opening is opened on the top surface of the end cover 11 , and a flange 18 facing the volute 13 is also provided at the opening.

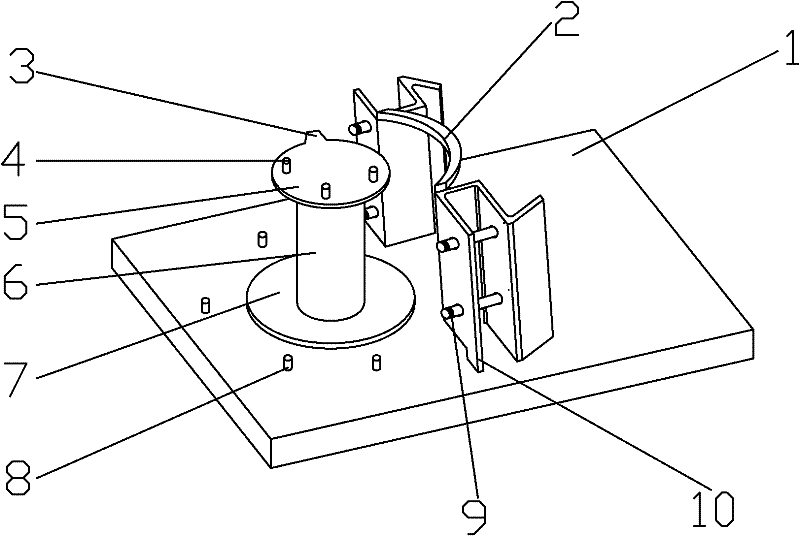

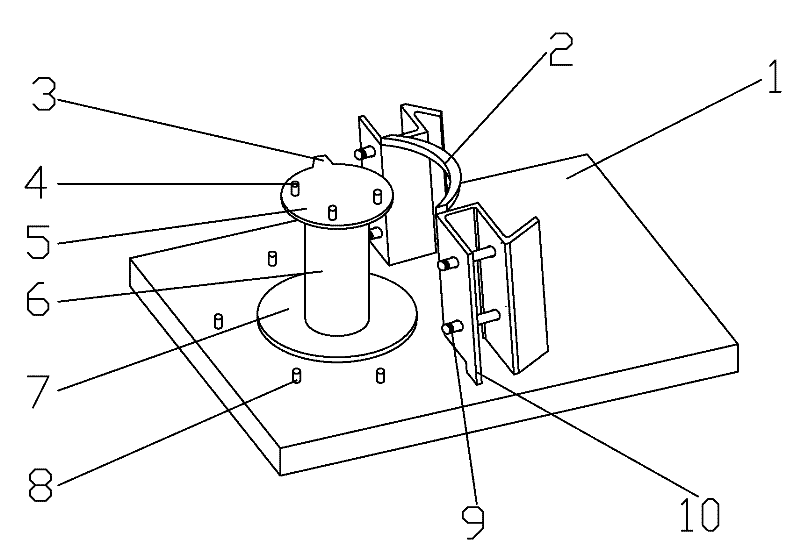

[0019] Such as figure 1 As shown, the assembly tooling of the harvester re-extractor shell of the present invention is used to assemble the volute 13, end cover 11 and flange 14 of the re-extractor shell into one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com