Bearing ring grinding workshop detection line

A bearing ring and detection line technology, which is applied in the field of detection line in the grinding workshop of bearing rings, can solve problems affecting the accuracy of detection, waste of time and space, and classification of out-of-tolerance products that cannot be processed, so as to improve production efficiency and quality , improve accuracy, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

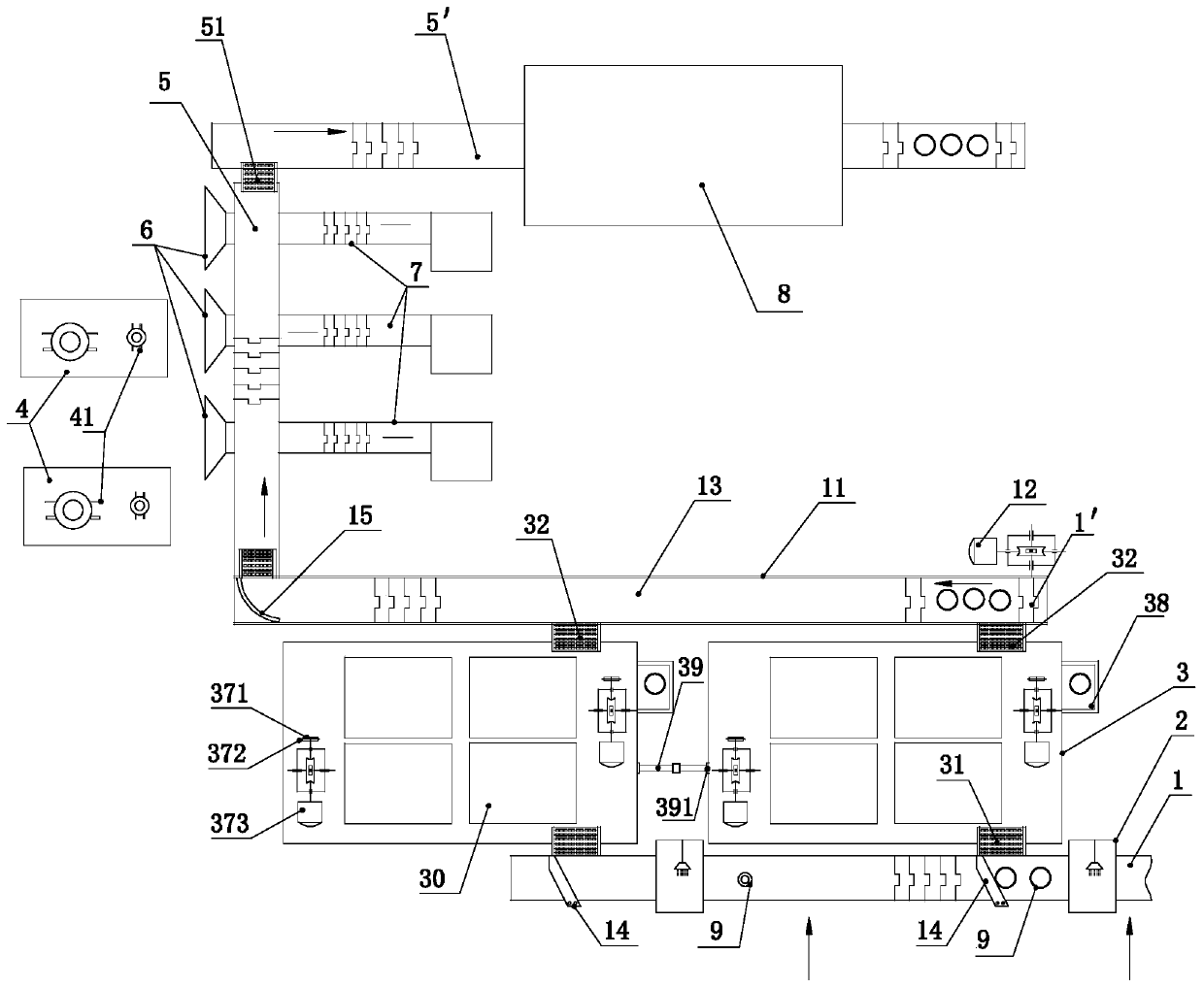

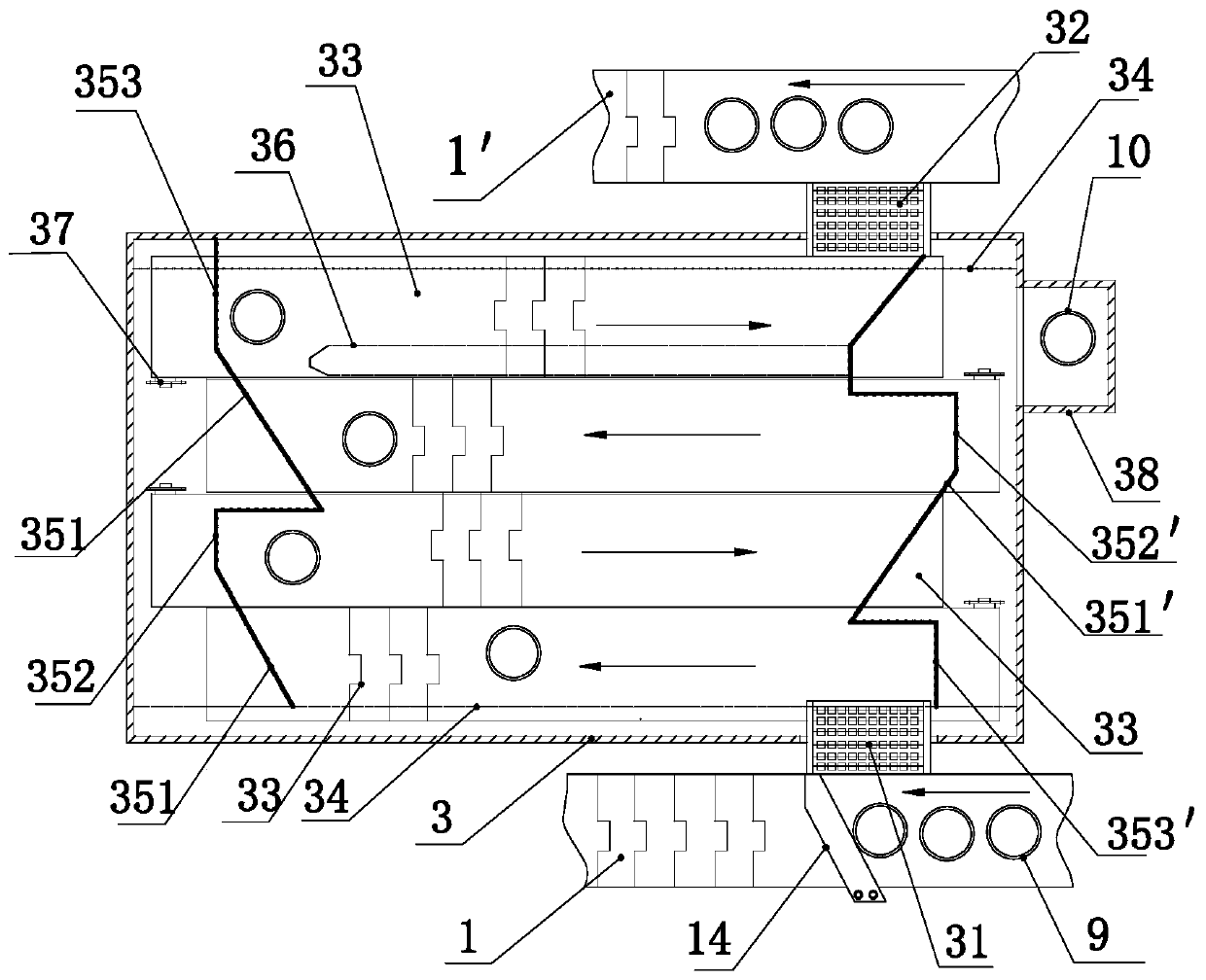

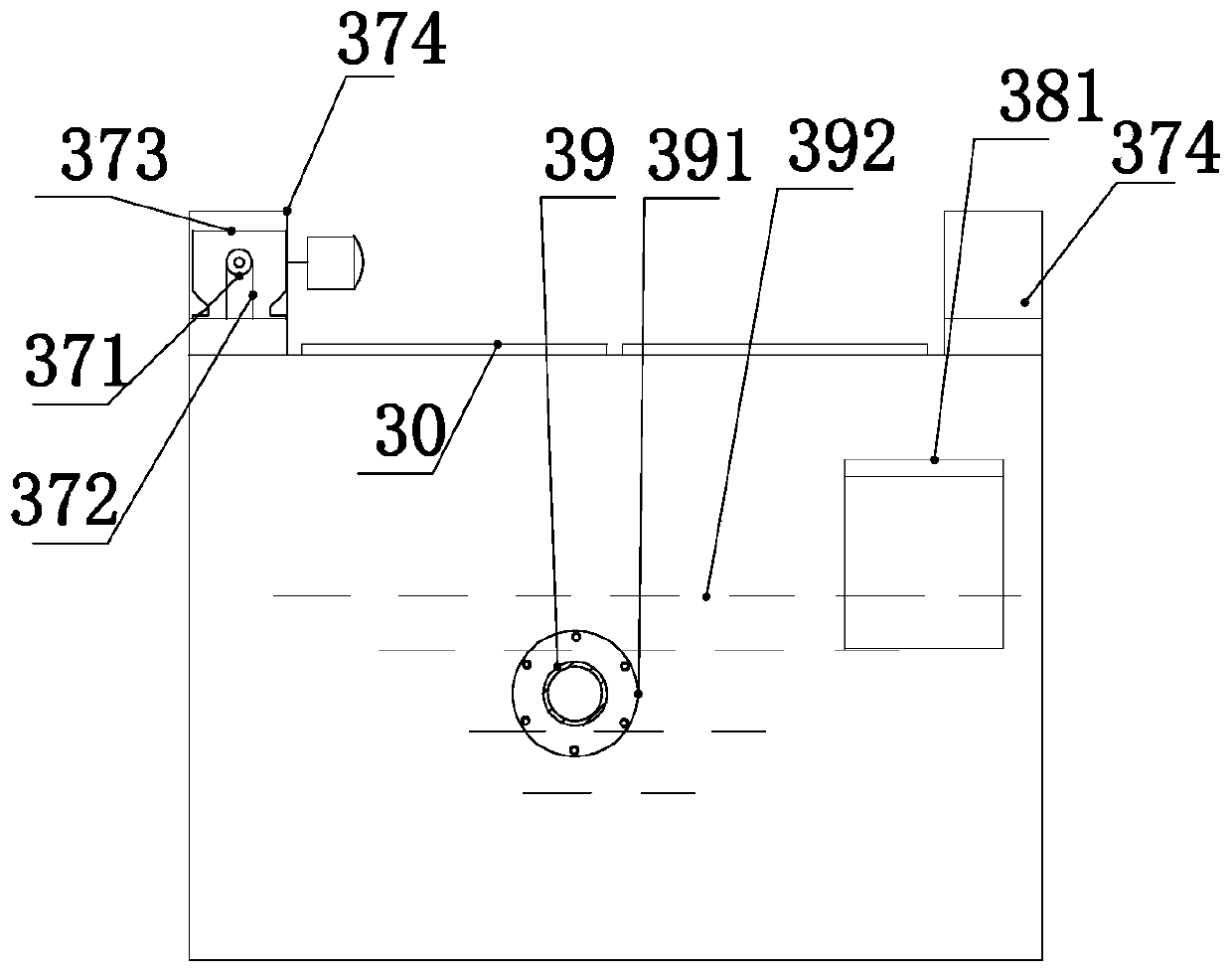

[0025] Such as Figure 1 to Figure 4 As shown, the present invention mainly includes a feed conveyor 1, a discharge conveyor 1', a spray box 2, an isothermal box 3, a detection table 4, a detection conveyor 5, a return conveyor 5', a classification tank 6, a classification Platform 7 and washing machine 8, the present invention will be described in detail below in conjunction with accompanying drawing.

[0026] Such as figure 1 As shown, the feeding conveyor 1 is arranged horizontally, and the feeding conveyor includes a supporting frame 11, a flexible belt 13 arranged on the supporting frame, a transmission roller matched with the flexible belt, and a transmission motor 12 for driving the transmission roller to rotate. , two distribution plates 14 arranged left and right are arranged above the feeding conveyor, the distribution plates are fixedly connected with the carrier frame, and the two distribution plates are rectangular plates and arranged in parallel. Two spray boxe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com