On-Line Prediction Method of Compressor Faults in Rail Vehicle Air Conditioning Units

A technology for air-conditioning units and rail vehicles, applied in forecasting, machine/engine, rail vehicle heating/cooling, etc., to achieve the effect of improving operational reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

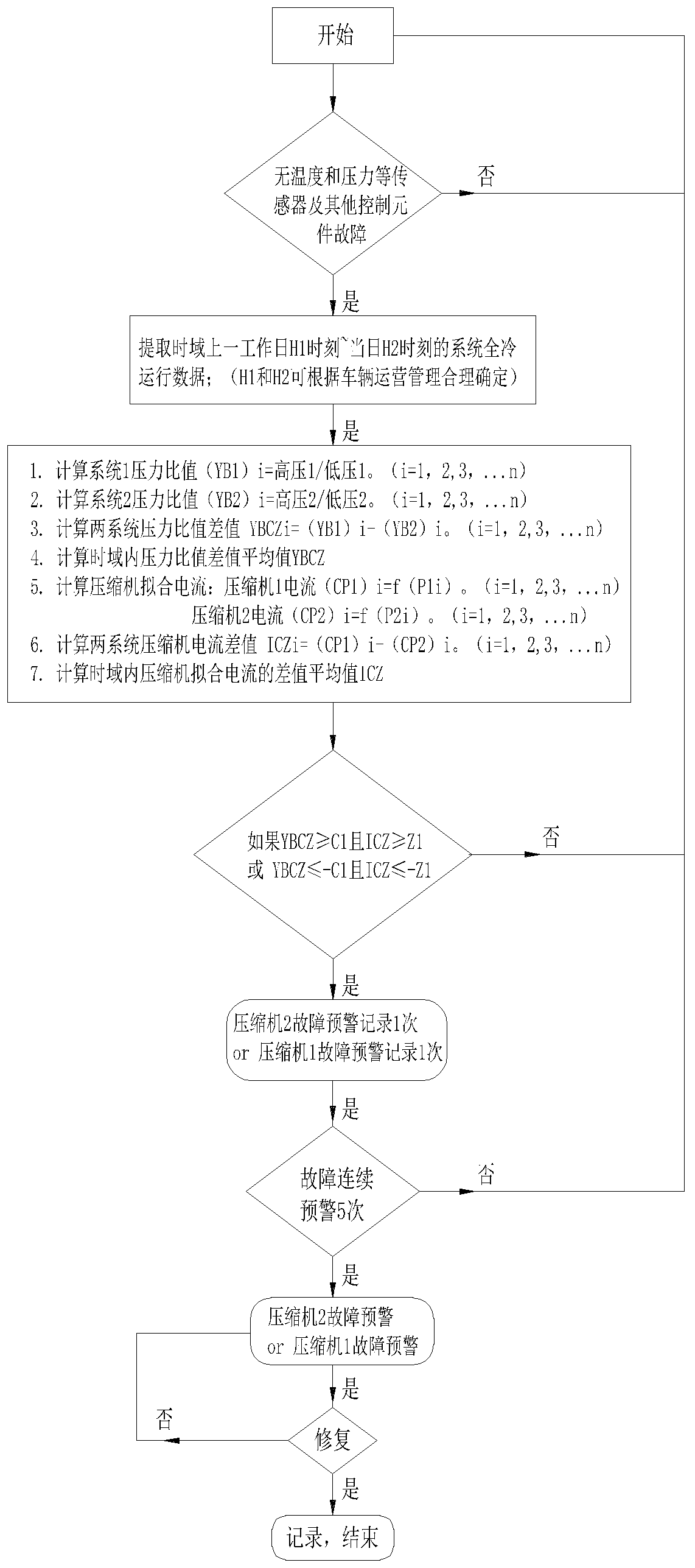

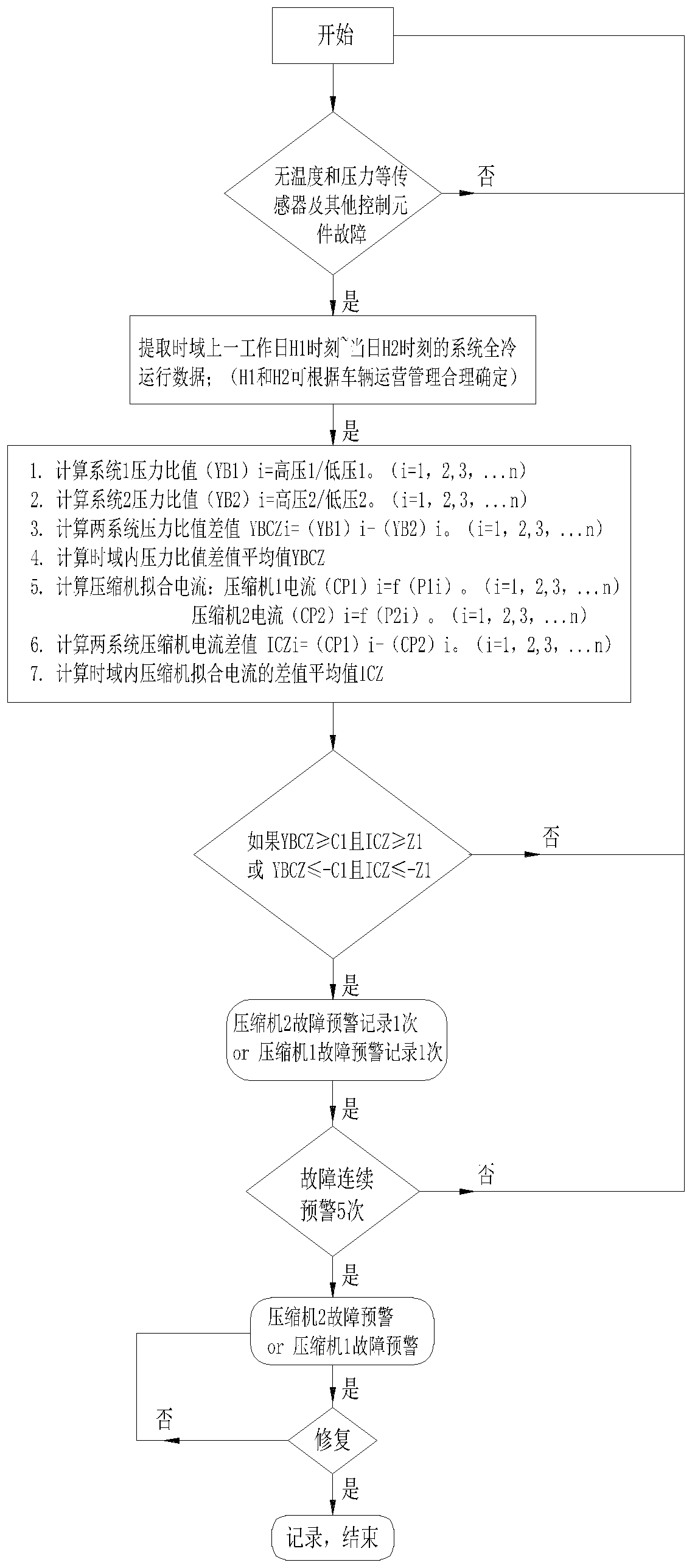

[0018] See attached figure 1 , the method of the present invention comprises the following steps.

[0019] Step A. Collect the discharge pressure and suction pressure data of the compressor during the operation of the air-conditioning unit at a certain period. Specifically, the collection cycle of the discharge pressure and suction pressure data of the compressor is H hours, for example, from the time H1 of the previous working day to the time H2 of the current working day. H, H1 and H2 can be reasonably determined according to the vehicle operation management time. For example, the data collection cycle of the discharge pressure and suction pressure of the compressor is 6, 12, 18 or 24 hours, which can be adjusted according to the vehicle operation management plan.

[0020] Step B. Calculate the ratio of the exhaust pressure value and the suction pressure value of the compressor in each group of refrigerant circulation systems according to a certain frequency in the collecte...

Embodiment 2

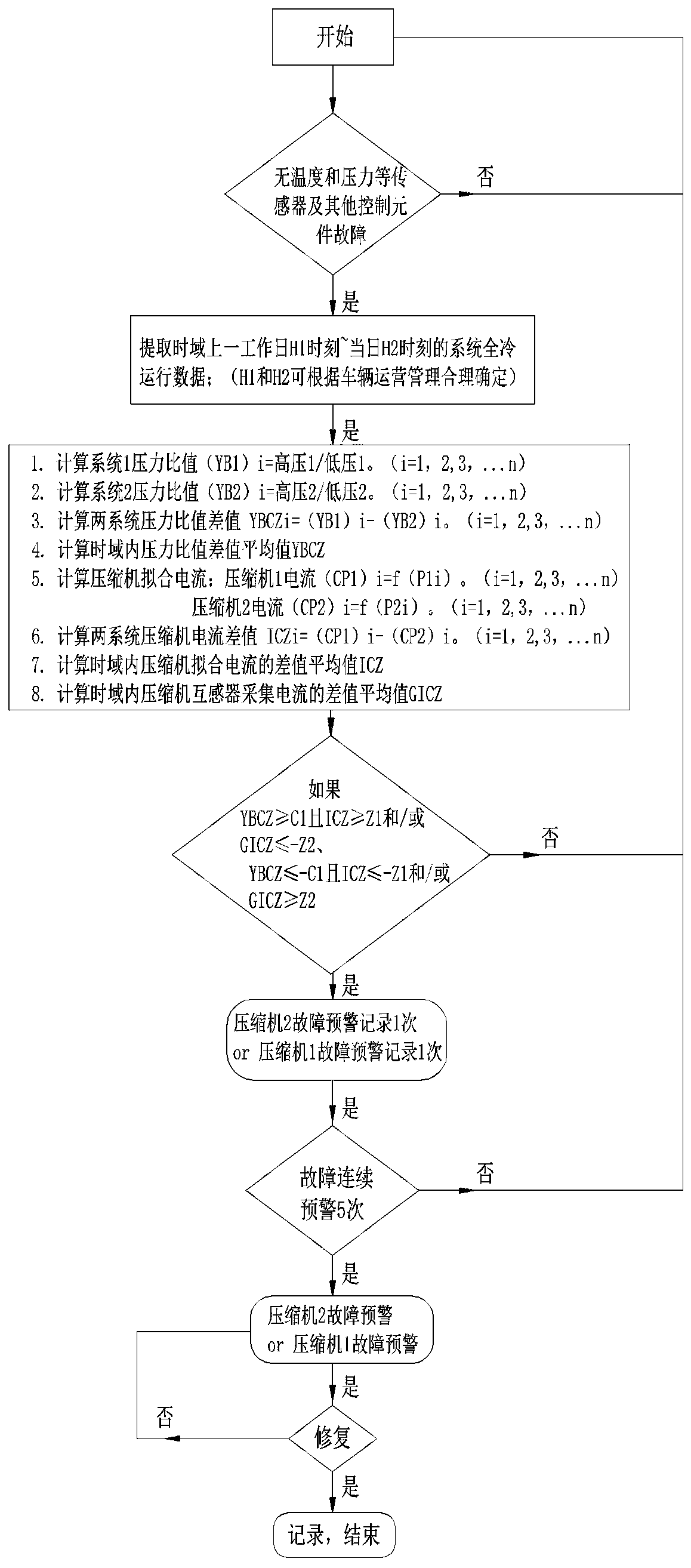

[0024] Embodiment 2: Different from Embodiment 1, in this embodiment, the air-conditioning unit is also provided with a current transformer for collecting the compressor current, and the accuracy of the method is further ensured by cooperating with the pressure sensor. When any one of the pressure sensor and the pressure sensor fails, the detection of compressor failure can still be realized.

[0025] See attached figure 2 , the method of the present invention comprises the following steps.

[0026] Step A. Collect the discharge pressure and suction pressure data of the compressor during the operation of the air-conditioning unit and the current data of the two sets of compressors collected by the current transformer in a certain period. Specifically, the collection cycle of the discharge pressure and suction pressure data of the compressor is H hours, for example, from the time H1 of the previous working day to the time H2 of the current working day. H, H1 and H2 can be re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com