Integrated real-time measurement device for longitudinal crawling and tight fit clearance of switch rail

A technology of real-time measurement and sharp rails, which is applied in the field of rail transit safety, can solve problems such as the inability to crawl on sharp rails and close gaps, comprehensive analysis of data changes, rules, and trends, installation interference of measuring devices, and difficulty in maintenance, etc., to achieve reduction Displacement measurement range, easy maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings and technical solutions.

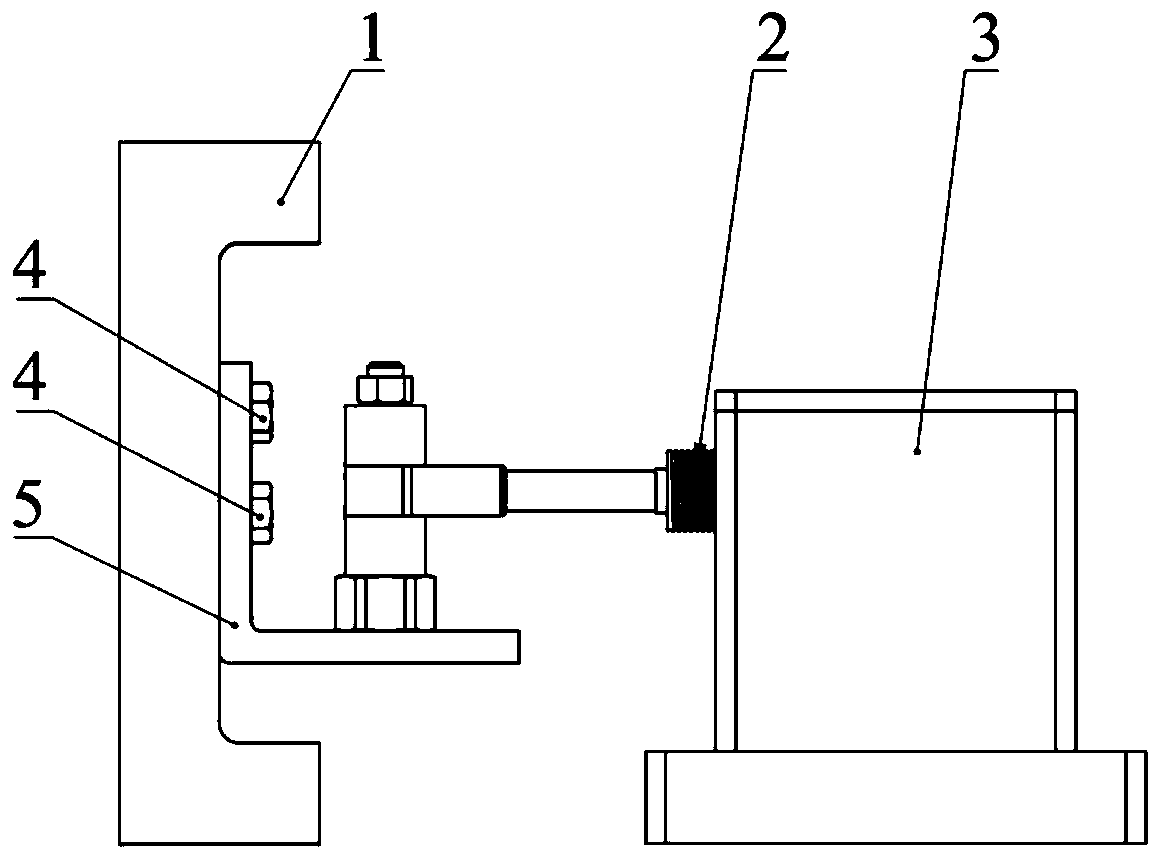

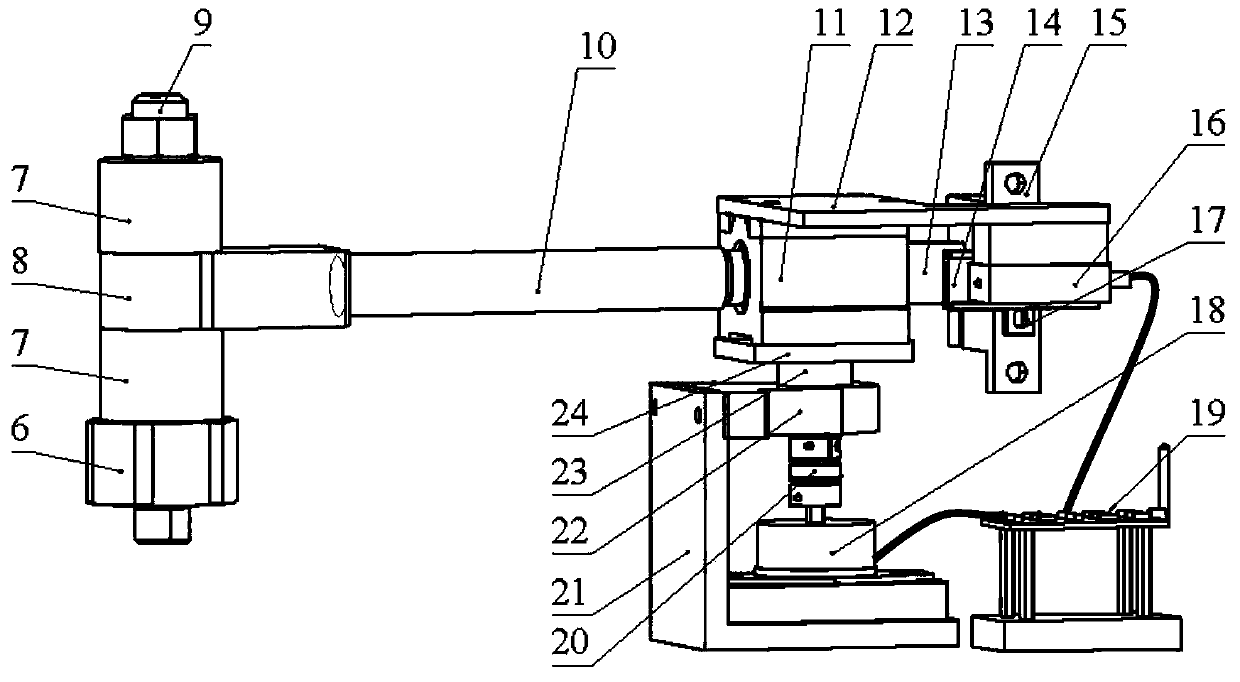

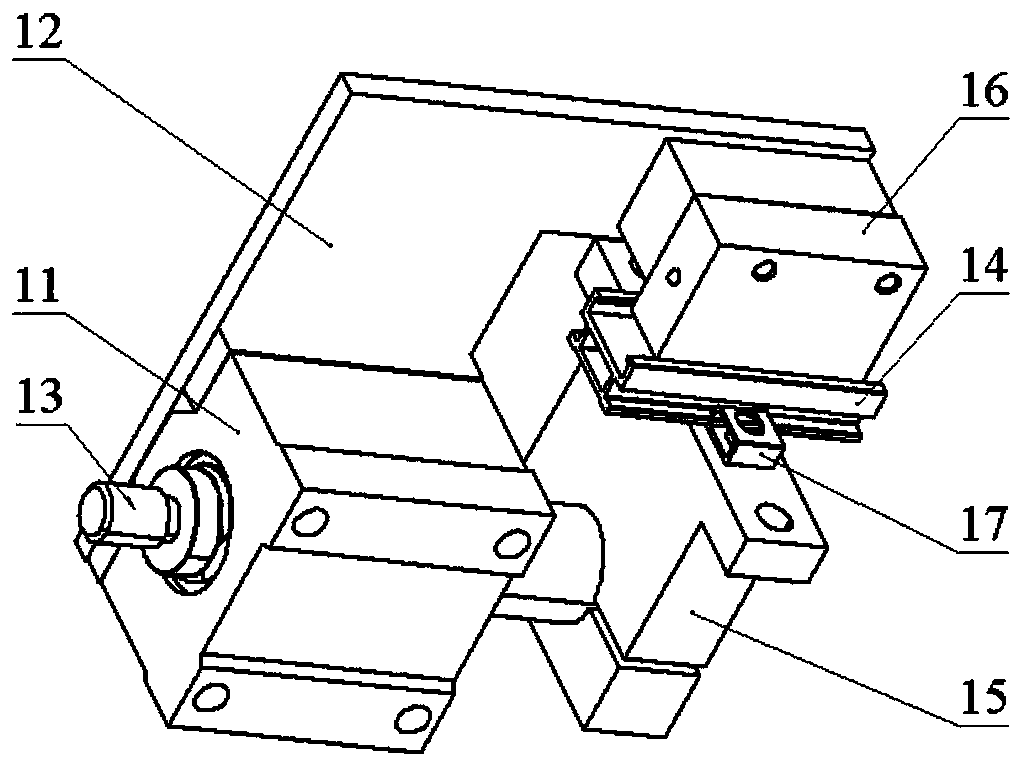

[0024] (1) if figure 1 and 4 As shown, the switch rail 1 is located inside the basic rail 25, and the switch machine pushes the switch rail 1 to move, keeping the switch rail 1 on one side and the basic rail 25 on the same side in a close contact state, and the switch rail 1 on the other side and the basic rail on the same side 25 is in the state of repelling, install two groups of point rail longitudinal crawling and close-fitting gap integrated real-time measuring devices of the present invention on the same section of the turnout rail (each turnout has a point rail on the inner side of the two basic rails, Both need to be monitored), the measuring device includes a displacement conversion transmission mechanism, a displacement sensor, an angle sensor and a data acquisition and processing unit. The displ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com