Material handling device

A technology for handling devices and materials, applied in the field of material handling devices, can solve the problems of cumbersome steps and low efficiency, and achieve the effects of high work efficiency, convenient maintenance and low maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

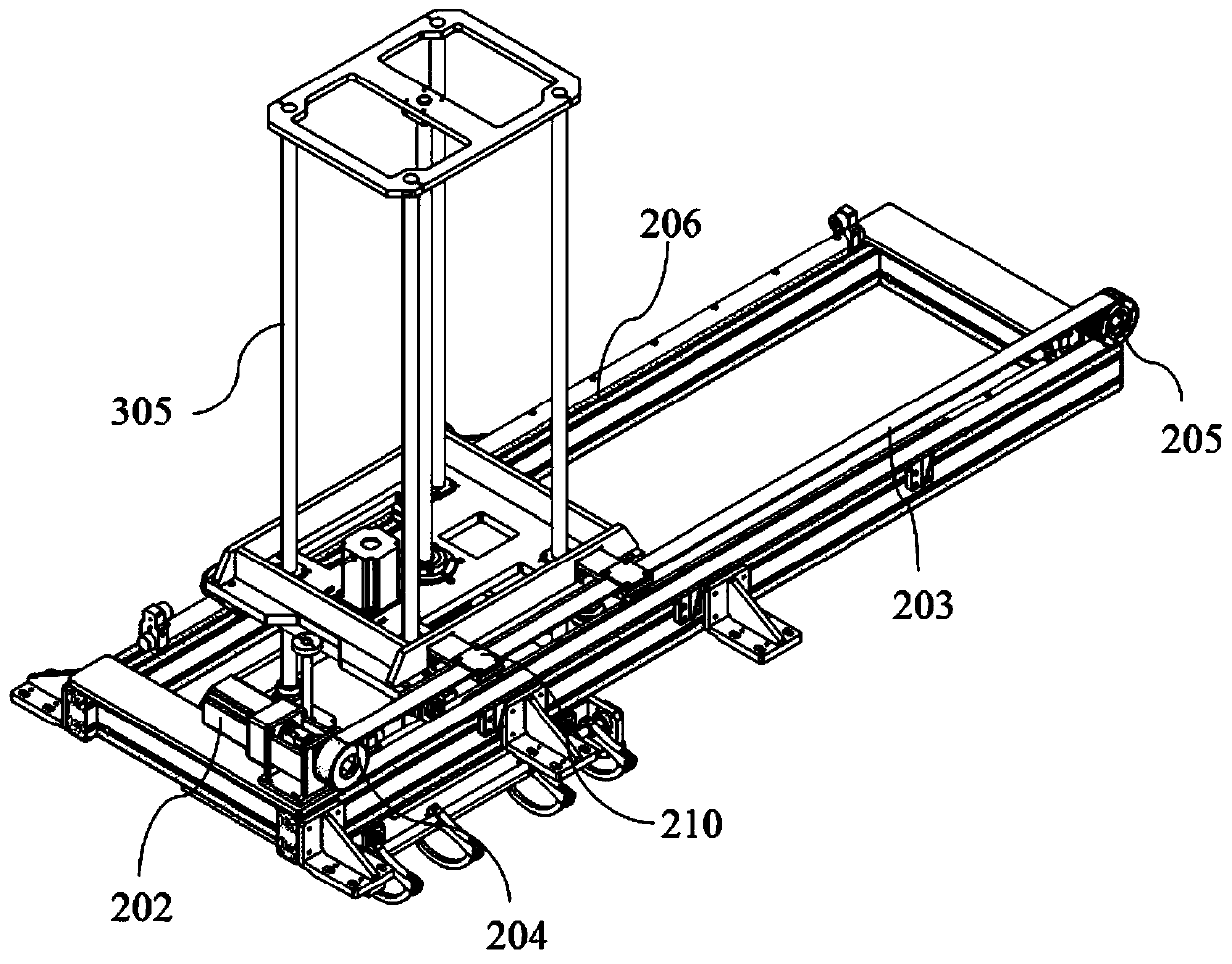

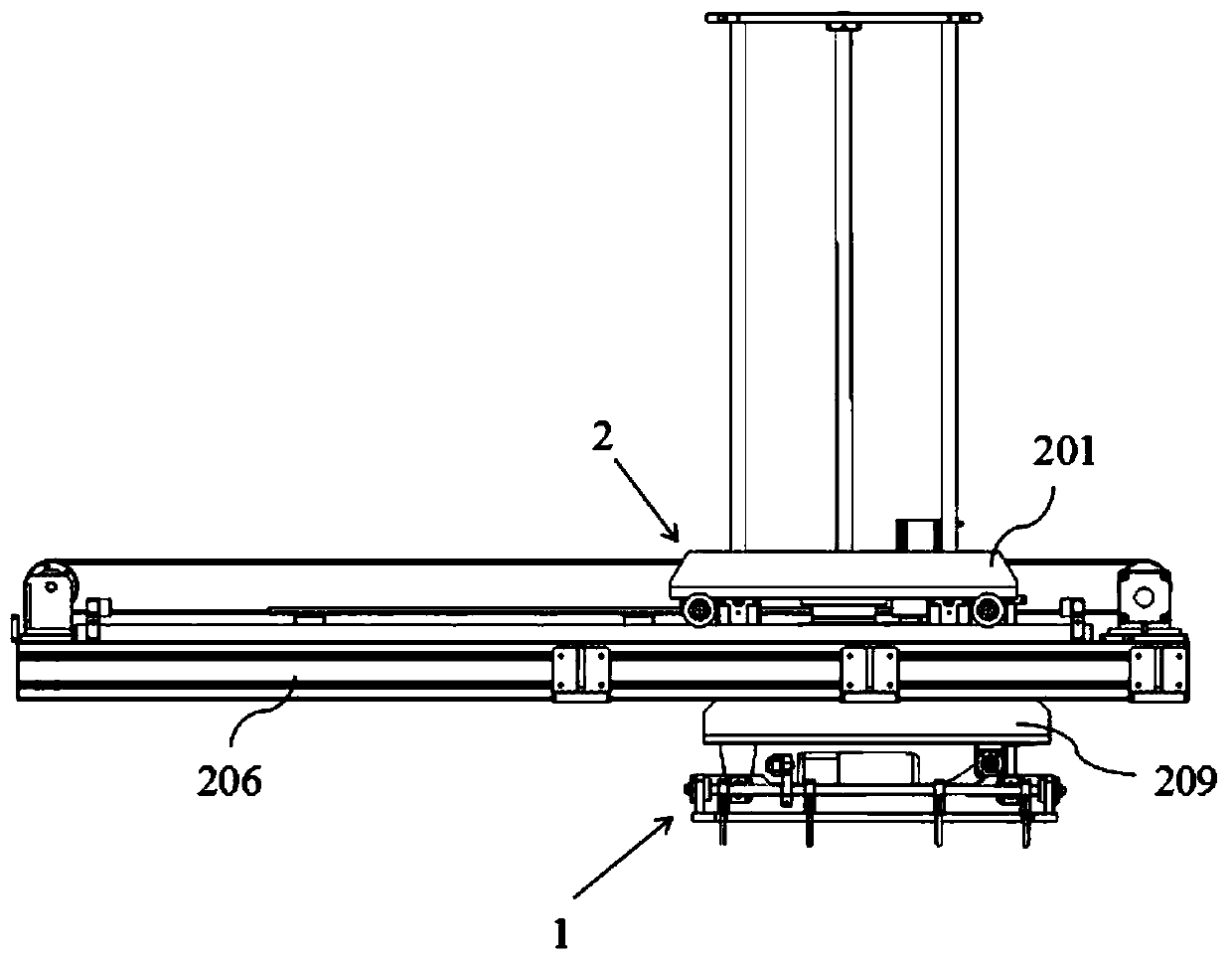

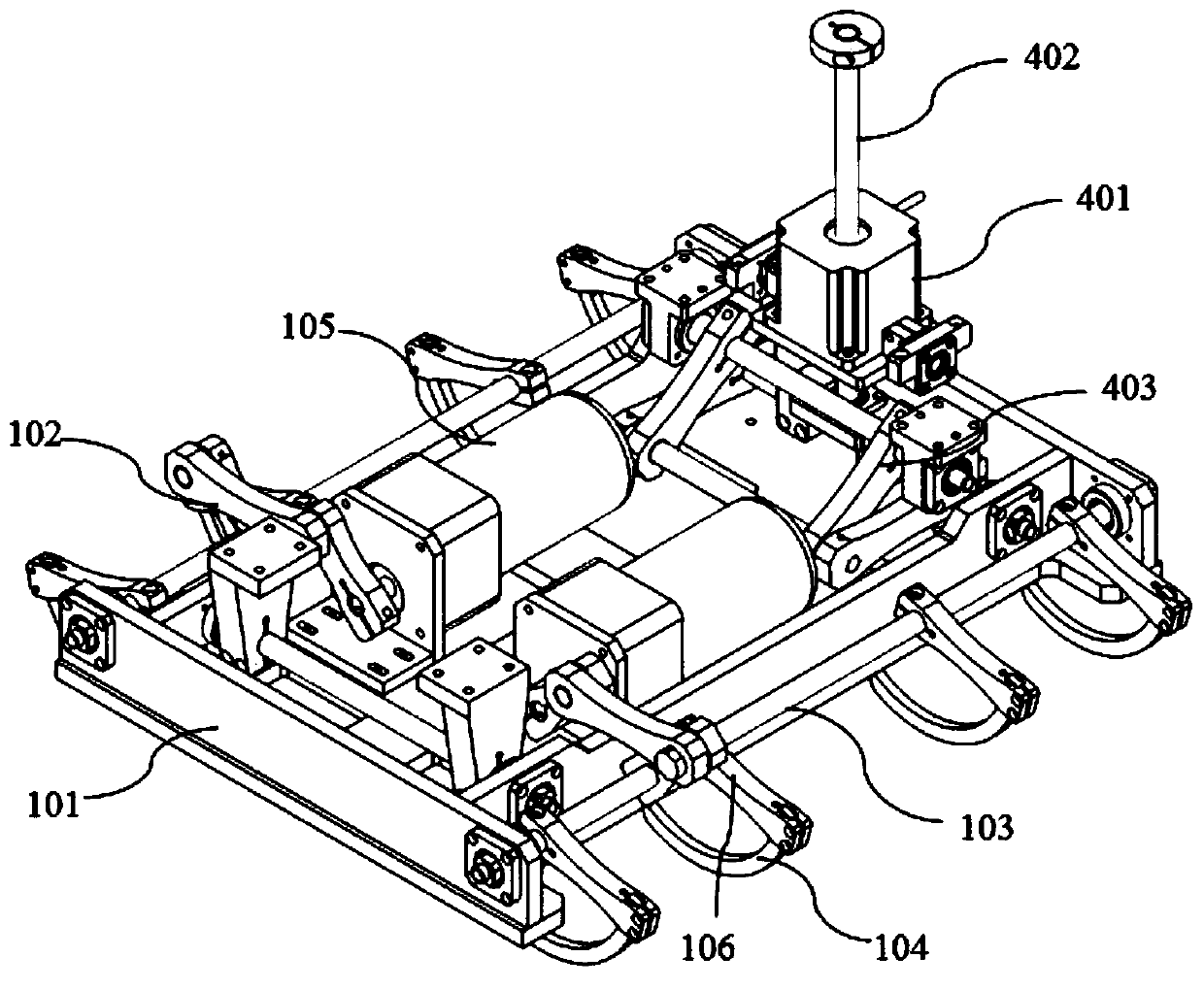

[0024] see Figure 1 to Figure 5 , a material handling device, which includes a transfer mechanism 2 and a transfer mechanism 2; the grabbing mechanism 1 includes a frame 101, a drive link 102 and a hook shaft 103; the frame 101 is provided with a hook Drive motor 105; the output shaft of described hook drive motor 105 is connected with an end of described drive link 102, and the other end of described drive link 102 is connected with hook rotating shaft 103; Several described insert hooks 104 pass through respectively The hook connecting rod 106 is connected to the hook shaft 103; the transfer mechanism 2 includes a transfer slide 201 and a transfer power mechanism, and the transfer slide 201 is connected to the frame 101. The transfer power mechanism is used to drive the transfer slide 201 to move along a predetermined track.

[0025] In this embodiment, the hook driving motor 105, the driving connecting rod 102, the hook rotating shaft 103, the hook connecting rod 106, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com